3

208/240V - 3 Phase - 50/60 Hz

PRESSURE

SWITCH

TIMER

RELAY

MANUAL

RESET

Timer Checkout

1) De-energizecompressor/controlcircuit.Insertsmall

screwdrivertoholdbellowslevertabdown(nopressure

position),seegure3.

2) Re-energizecompressor/controlcircuit–timershouldthen

beenergizedandstopthecompressorinthepresettime

period.Aftercheckout,theFD113timermustbereset.

Pressure Checkout

1) ToaccuratelychecktheoperatingpressureoftheFD113,

thecompressormustbede-pressurized,theFD113“Oil”

and“Low”pressurelinesdisconnectedandacheck

performedasoutlinedin“pressurecheck”underthe

checkingandadjustingprocedure.

CONTROL CHECKOUT

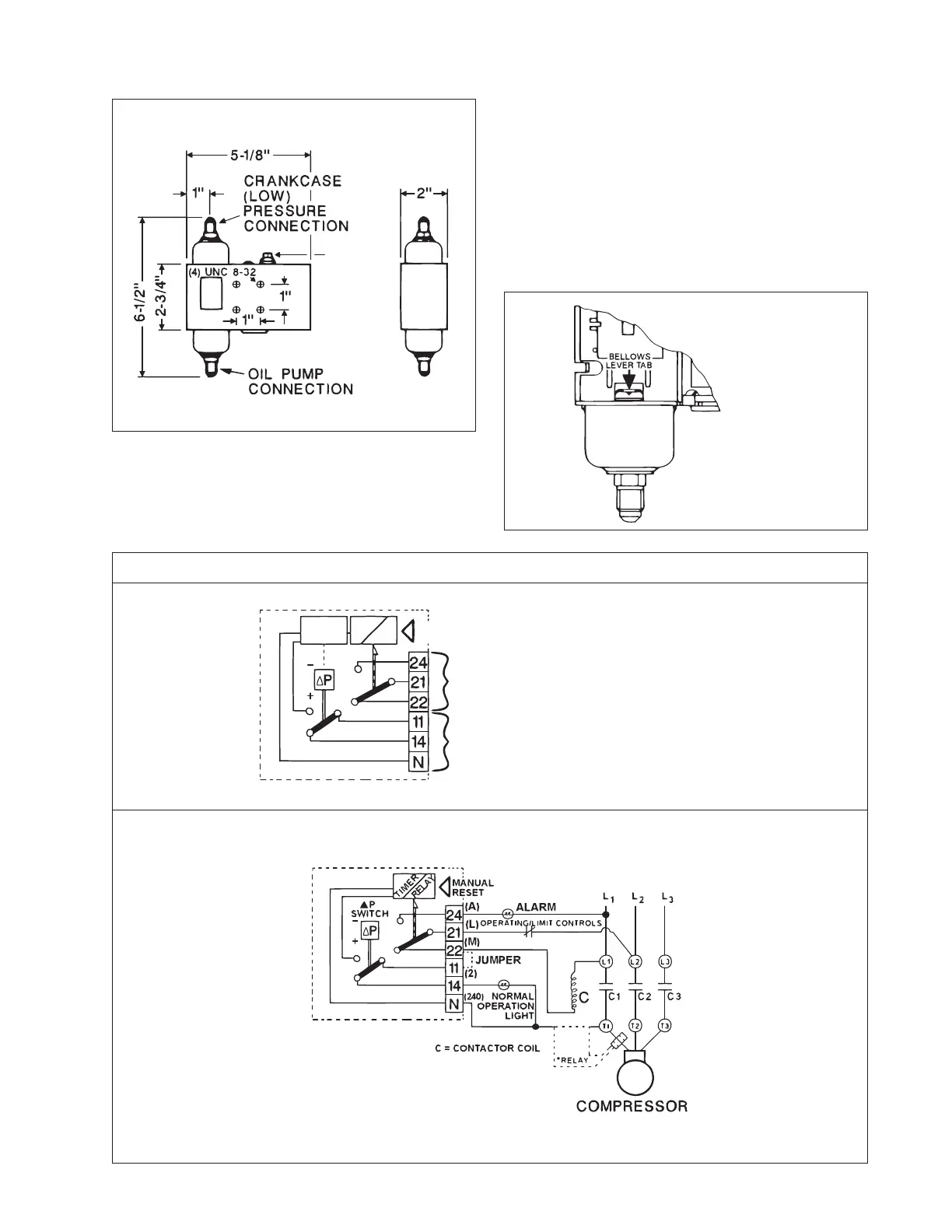

FIGURE 2—FD113 MOUNTING DIMENSIONS

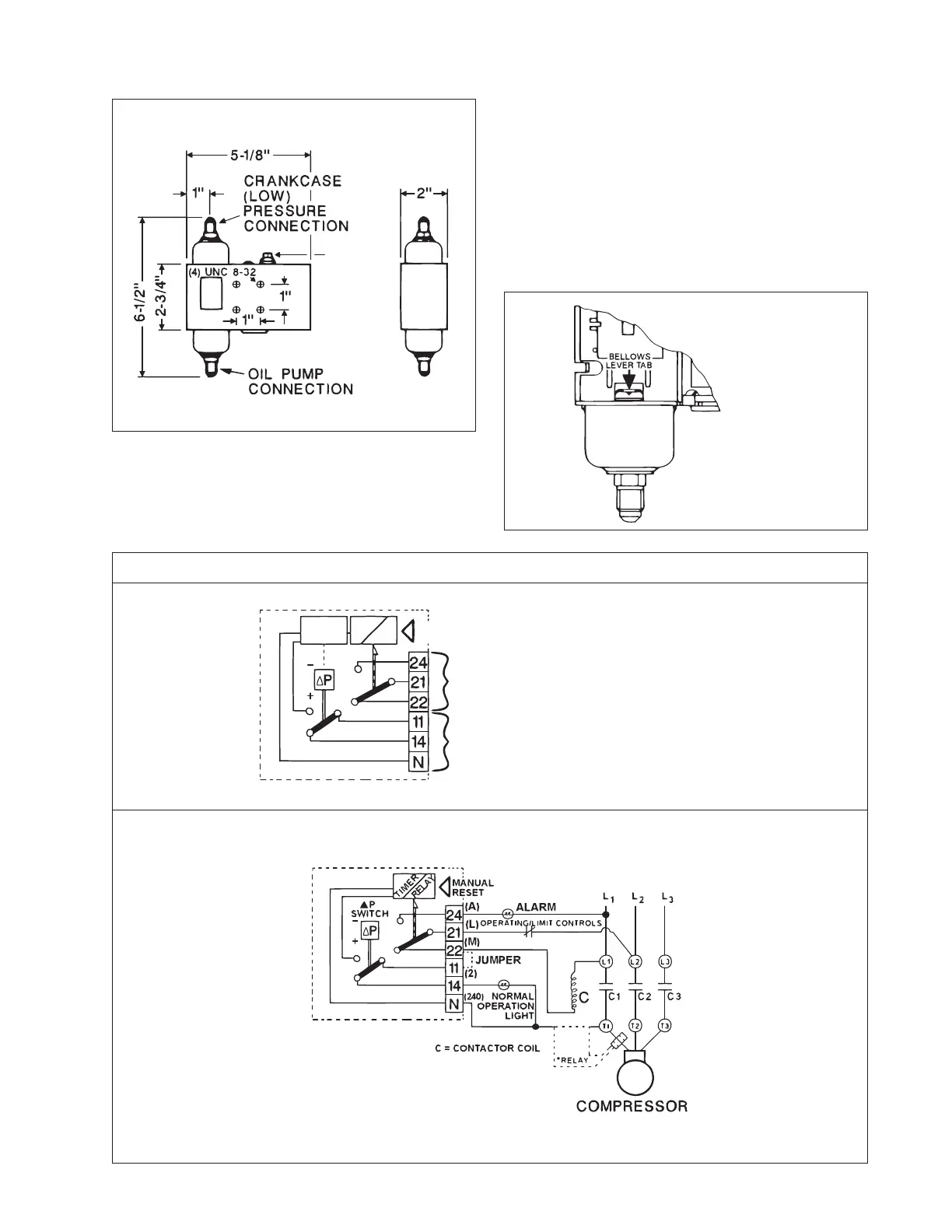

Contacts below are shown in normal run condition with oil pressure.

Typical Old Copeland 3-Wire Oil Pressure Safety Control Wiring

Manualresettimercontacts.Terminal21to22closed

duringnormalrunandduringtime-out–openontime-out.

Terminals21/24(signal)closedaftertime-out.

PowertoTimerthrupressureswitchcontacts.Duringnormalrun,

11/14closedfor“safelight”circuit.Onlossofpressure,11/14open

andtimerisenergizedfortimedelayperioduntiltrip-out.

FIGURE 4

FIGURE 3

* Optional Current Sensing RelayinSerieswithN/T1line

forcompressorswithinternallinebreakmotorprotectors.

(Preventsoilpressuresafetycontrolfromtrippingwheninternal

line-breakmotorprotectortrips.)

FIGURE 5

TIMER

RESET

BUTTON

Loading...

Loading...