Instruction Manual

D102087X012

585C Actuator

October 2013

15

a. To open or close the valve manually or to position the valve at any point in the stroke, regardless of the cylinder

pressure. The tapered pin is inserted during manual throttling operation.

b. To act as a travel stop to limit full opening or closing of the valve but not both at the same time. The tapered pin

is left out when the assembly is used as a travel stop.

c. To open or close the valve manually in an emergency without the necessity of inserting the tapered pin.

Bevel gears are used in sizes 60 and 68 and worm gears in sizes 80 through 130. A spring-loaded ball detent is provided

in the handwheel to prevent a change in setting due to vibration. The following table 10 lists pertinent information on

these handwheel units.

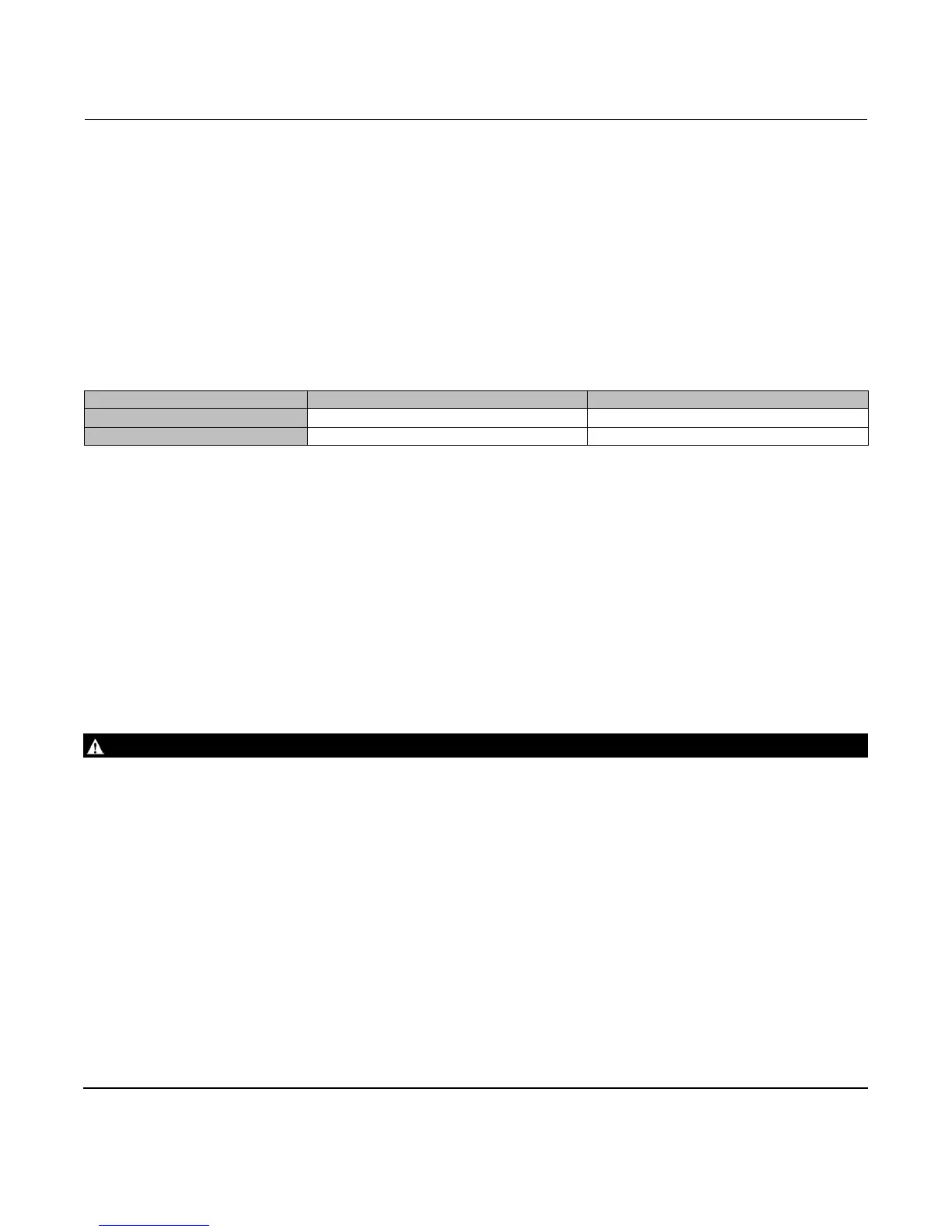

Table 10. Handwheel Information

Actuator Size 60-68 80-130

Handwheel Diameter, Inches 8 17

Turns Required for One Inch of Travel 16 10

Maintenance (Sizes 25 & 50)

Actuator parts are subject to normal wear and must be inspected and replaced as necessary. The frequency of

inspection and replacement depends on the severity of service conditions. This section provides two separate

procedures, one on Replacing Handwheel Housing O-Ring or Thrust Bearings, and the other on Replacing Seals,

Changing Action, or Changing Bias Spring(s).

Refer to figures 5 and 7.

For an actuator with handwheel, a grease fitting (key 50) is provided on the bearing cover (key 38) for periodic bearing

lubrication with lithium grease (key 24).

WARNING

Avoid personal injury from sudden release of process pressure. Before performing any maintenance operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal

injury.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator c annot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

on both s ides of the valve. Drain the process media from both sides of the valve.

D Vent the power actuator loading pressure and release all bias spring compression force by slowly unscrewing the

cylinder cover bolting in a crisscross pattern.

D Use lock-out procedures to be sure that the above measures stay in effect while you work on the equipment.

D The valve packing box may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings, or when

loosening the packing box pipe plug.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

Loading...

Loading...