!

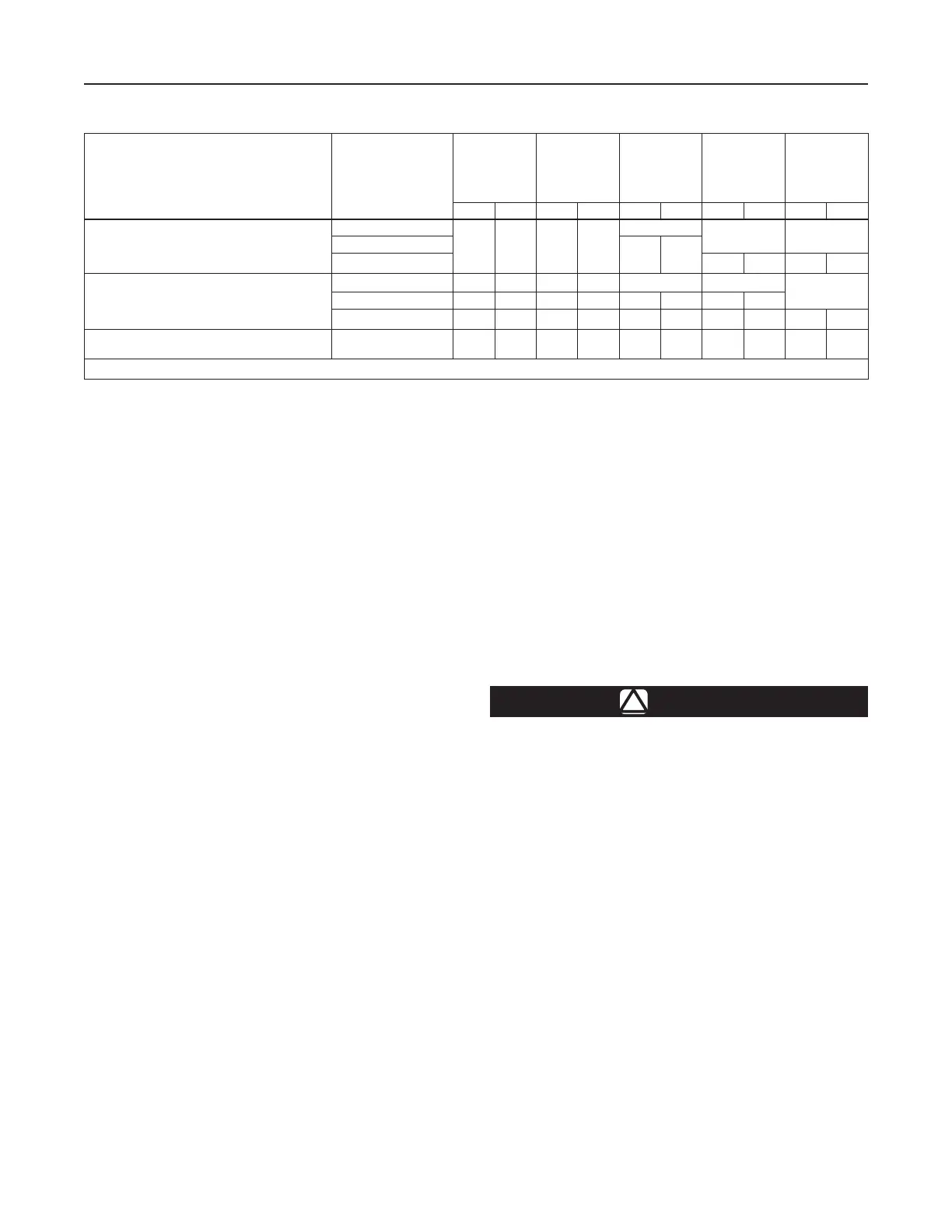

Table 2. Maximum Spring and Diaphragm Casing Pressure

(1)

MAXIMUM PRESSURE DESCRIPTION

DIAPHRAGM

CASING MATERIAL

TYPES 627

AND 627OSX

TYPES 627R

AND 627LR

TYPES 627M

AND

627MOSX

TYPE 627MR

TYPES 627H,

627HM,

627HOSX

AND

627HMOSX

psig bar psig bar psig bar psig bar psig bar

Maximum pressure to spring and diaphragm

casings to prevent leak to atmosphere other than

relief action (internal parts damage may occur)

Die cast aluminum

250 17.2 250 17.2

Not Available

Not Available Not Available

Ductile iron

250 17.2

Steel or Stainless steel 250 17.2 800 55.2

Maximum pressure to spring and diaphragm

casings to prevent burst of casings during

abnormal operation (leak to atmosphere and

internal parts damage may occur)

Die cast aluminum 375 25.9 375 25.9 Not Available Not Available

Not Available

Ductile iron 465 32.1 465 32.1 465 32.1 465 32.1

Steel or Stainless steel 1500 103 1500 103 1500 103 1500 103 1500 103

Maximum diaphragm casing overpressure (above

setpoint) to prevent damage to internal parts

All materials 60 4.1 120 8.3 60 4.1 120 8.3 120 8.3

1. If the spring case is pressurized, a metal adjusting screw cap is required. Contact your local Sales Oce for details.

Type 627M or 627HM Regulator

De-Icer System Application

For the Type 627M or 627HM regulator de-icer system,

refer to the application shown in Figure 3. With a large

pressure drop across the working regulator, ice can form

within this regulator. The formation of ice decreases the

size of the orifice, so the regulator is unable to supply

enough flow to satisfy the downstream demand. When the

downstream pressure falls below the outlet pressure setting

of the Type 627M or 627HM regulator, the disk assembly

of the Type 627M or 627HM regulator moves off its orifice,

permitting alcohol to flow into the main gas line. The alcohol

carried to the main regulator by the flowstream prevents

additional ice from forming on the orifice. When normal

flow resumes and as pressure in the downstream system is

restored, the Type 627M or 627HM regulator shuts off.

Overpressure Protection

627 Series regulators have outlet pressure ratings that are

lower than their inlet pressure ratings. A pressure-relieving

or pressure-limiting device must be provided by the user for

the Types 627, 627H, 627M and 627HM regulators if the inlet

pressure can exceed the outlet pressure rating, since these

regulators do not have internal relief.

Types 627R and 627LR regulators provide internal relief

which limits the total outlet pressure buildup over setpoint.

Use Tables 3 and 4 to determine the total outlet pressure.

This internal relief may be adequate for the application, if

not, provide additional pressure relief or a pressure-limiting

device downstream.

Types 627OSX utilizes integral slam-shut device to provide

overpressure and underpressure protection by completely

shutting off the flow of gas to the downstream system.

Pressure is registered on one side of the diaphragm, piston

or bellows and is opposed by the setpoint control spring of

the manometric sensing device. The Type OS2 slam-shut

valve tripping pressure is determined by the setting of the

control spring.

WARNING

Overpressure–When the downstream pressure increases

above the setpoint, the pressure on top of the diaphragm

overcomes the spring setting and moves the manometric

device stem.

Underpressure–When the downstream pressure decreases

below the setpoint, the control spring pressure below the

diaphragm overcomes the downstream pressure and pushes

the diaphragm which moves the manometric device stem.

See Type OS2 Instruction Manual (D102778X012) for

additional information.

Startup and Adjustment

Startup

To avoid personal injury or property damage

due to explosion or damage to regulator or

downstream components during startup,

release downstream pressure to prevent an

overpressure condition on the diaphragm of

the regulator.

In order to avoid an overpressure condition

and possible equipment damage, pressure

gauges should always be used to monitor

pressures during startup.

1. Slowly open the upstream shut-off valve.

2. Slowly open the downstream shut-off valve.

3. Check all connections for leaks.

4. Make final control spring adjustments according to the

adjustment procedures.

6

627 Series

Loading...

Loading...