Instruction Manual

D100310X012

667 Actuator (Size 30/30i - 76/76i and 87)

May 2018

14

6. Remove the following connected parts: the diaphragm (key 3), upper diaphragm plate (key 4), spacer (key 2), cap

screw (key 12), lower diaphragm plate (key 71), and actuator stem (key 144). Be careful when pulling the threads of

the actuator stem through the seal bushing (key 7) to avoid damaging the O‐rings (key 8).

7. Remove the cap screw (key 12) to separate the parts of this assembly.

8. To remove the seal bushing, remove the snap ring (key 72), and lift out the bushing. Inspect, and if necessary,

replace O‐rings (keys 8 and 9).

9. Remove cap screws (key 30), and take off the lower diaphragm casing (key 64) and the gasket (key 70, size 30/30i

through 60/60i and 76/76i) or O‐ring (key 70, size 70/70i or 87). If necessary, the down travel stops (key 77) can be

removed.

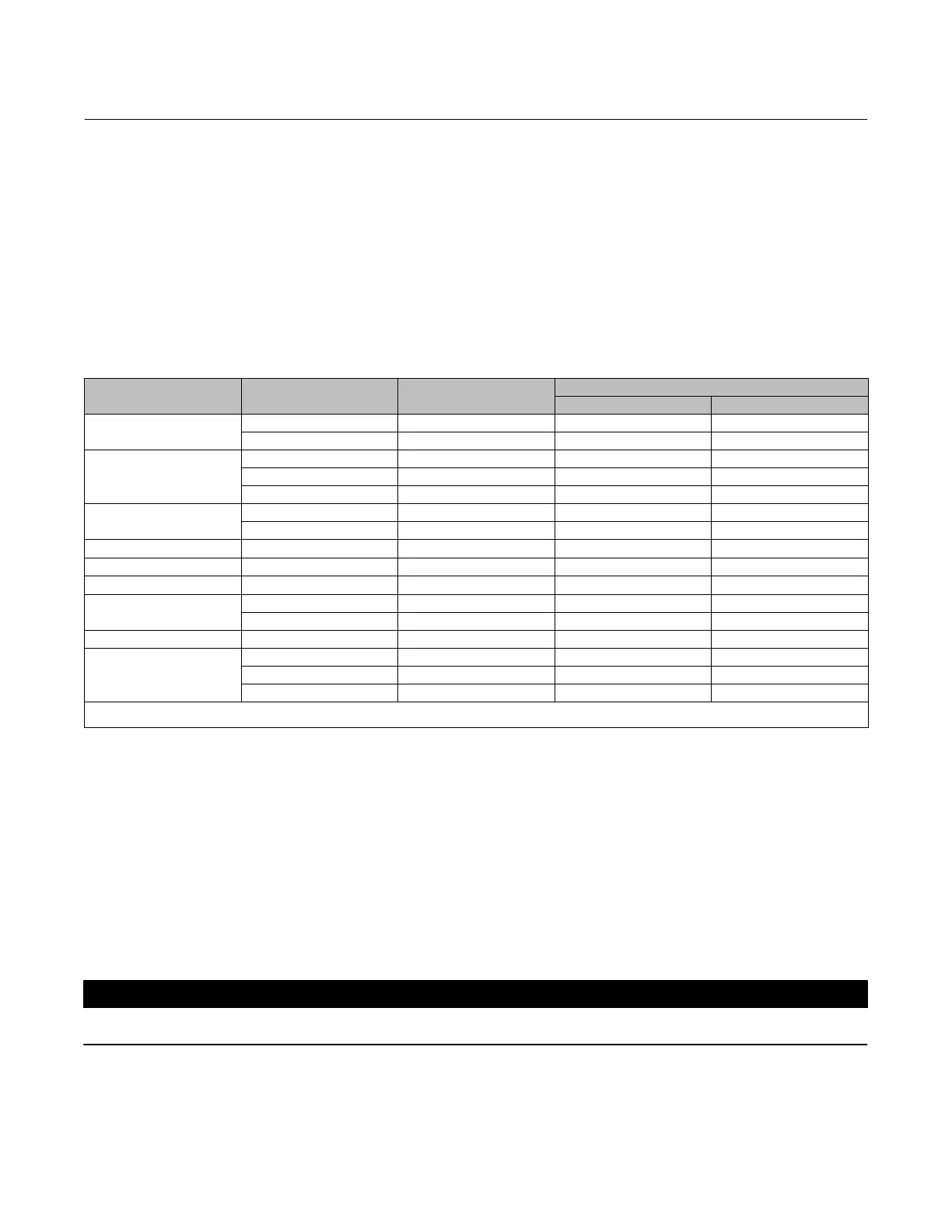

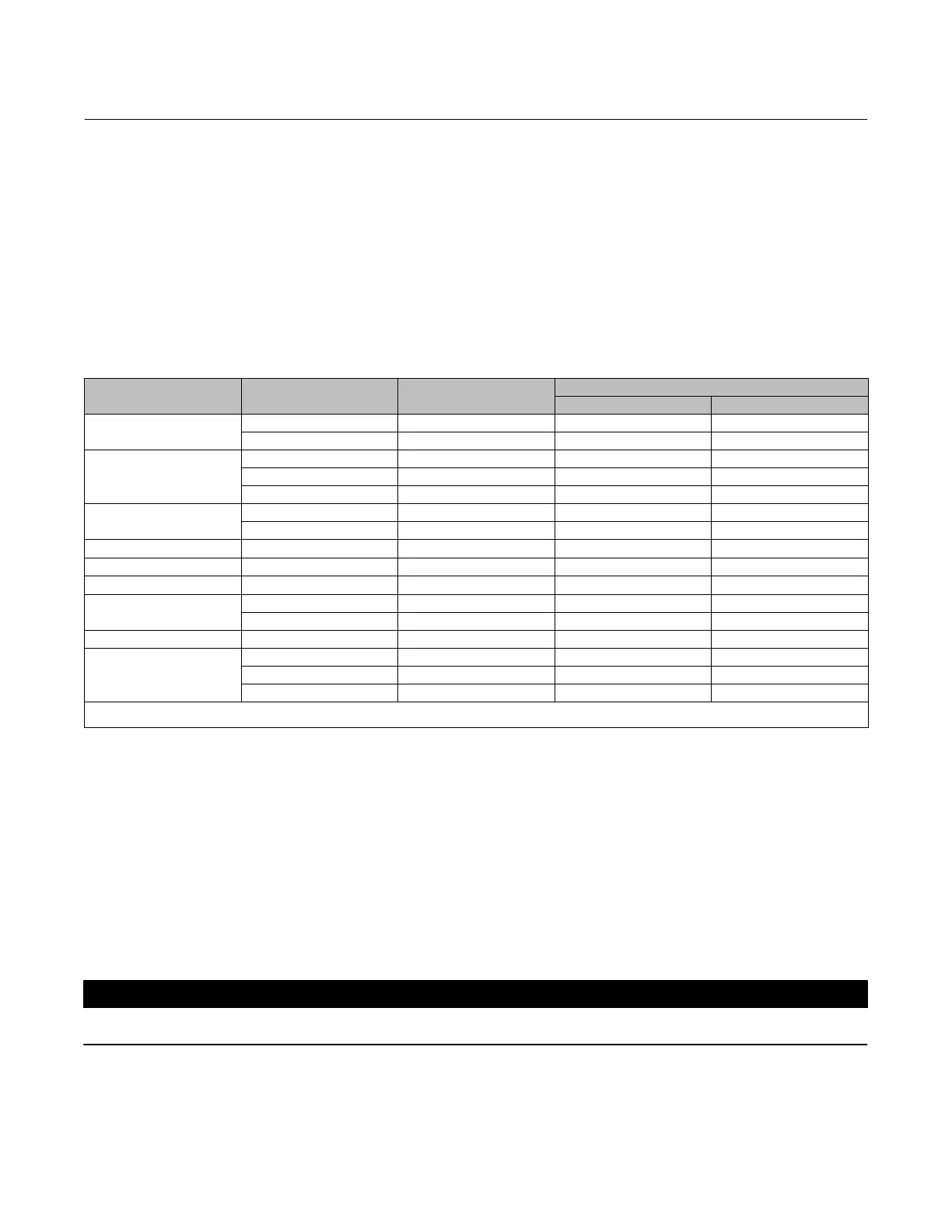

Table 2. Actuator Assembly Recommended Torque Values

DESCRIPTION, KEY

NUMBER

ACTUATOR SIZE THREAD SIZE, INCH

TORQUE

N•m Lbf•ft

Casing to yoke, key 30

(1)

30/30i to 60/60i and 76/76i 3/8-16 41 30

70/70i and 87 1/2-13 95 70

Travel stop, key 12

30/30i 3/8-24 41 30

34/34i and 40/40i 1/2-20 68 50

45/45i to 76/76i and 87 3/4-16 183 135

MO U-bolt nut, key 170

34 and 40 1/2-13 81 60

45 to 60 5/8-11 163 120

MO U-bolt nut, key 147 34 and 40 3/8-16 41 30

MO U-bolt nut, key 144 45 to 60 3/8-16 41 30

Diaphragm casing, key 14

(1)

30/30i to 76/76i and 87 3/8-24 27 20

Hex cap screw,key 256

34i to 40i 1/2-13 92 68

45i to 60i 5/8-11 163 120

Hex cap screw,key 257 34i to 60i 3/8-16 39 29

Stem connector, key 26

(2)

30/30i through 40/40i 5/16-18 23 17

45/45i through 70/70i 3/8-16 39 29

87 1/2-13 91 67

1. Observe tightening pattern and procedure described in the appropriate Actuator Assembly section.

2. Torque values when lithium grease is used on the threads.

Actuator Assembly

Refer to table 2 as appropriate.

1. Coat the O‐rings (key 70/70i, sizes 70 and 87) with lithium grease (key 237), or, coat the gasket with lithium grease

(key 237). Place a new gasket or O‐ring (key 70) on the yoke (key 73). Position the lower diaphragm casing (key 64)

on the yoke and align the holes. Insert the cap screws (key 30) and tighten evenly in a crisscross pattern to 41 NSm

(30 lbfSft) for size 30/30i‐60/60i and 76/76i actuators or 95 NSm (70 lbfSft) for size 70/70i and 87 actuators. If down

travel stops (key 77) were removed, insert and tighten them.

2. Coat the O‐rings (keys 8 and 9) with lithium grease (key 237) and place the O‐rings in the seal bushing (key 7).

3. Fill the seal bushing with lithium grease (key 237), slide the bushing into the yoke (key 73), and install the snap ring

(key 72).

CAUTION

Be careful during assembly to avoid damaging the O‐rings (key 8).

4. Assemble the actuator stem (key 144), lower diaphragm plate (key 71), diaphragm (key 3), upper diaphragm plate

(key 4), and the travel stop cap screw and spacer (keys 12 and 2). Coat the cap screw threads with lithium grease

Loading...

Loading...