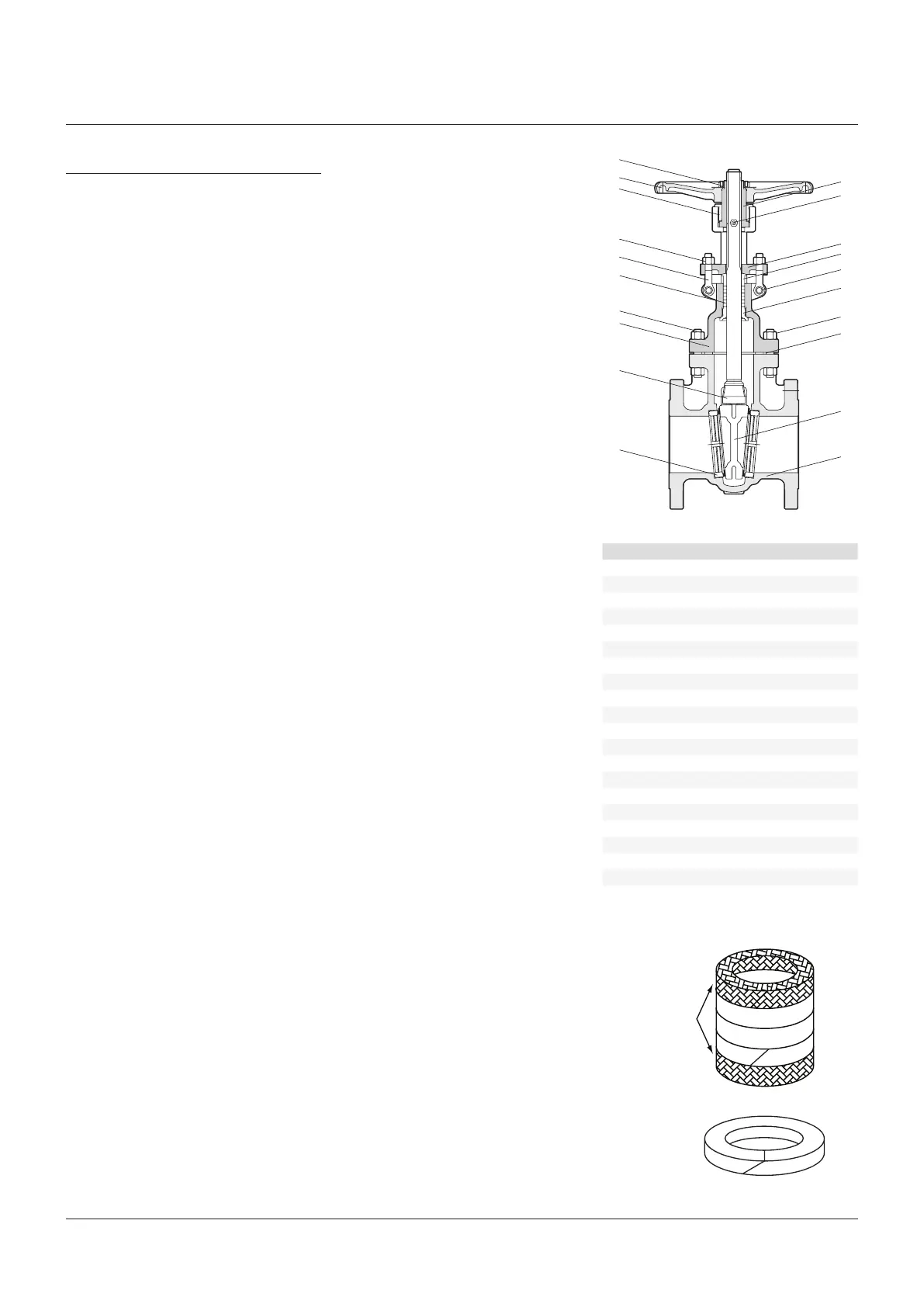

3

20

19

18

17

16

14

13

12

15

11

10

09

07

08

06

05

03

02

01

04

HANCOCK CAST STEEL - GATE, GLOBE AND CHECK VALVES

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

2 GATE VALVES

2.1 Installation and operation

2.1.1 Prior to installation

Valves not required for immediate use should

be stored under clean conditions to reduce the

risk of foreign matter entering the valve during

unpacking. If the valves are unpacked for

checking purposes, they should be immediately

re-packed until required for use.

Protection caps fitted to inlet and outlet

connections must be removed, but not until

immediately prior to installation.

Seating faces should be wiped clean with a

drycloth before commencing installation.

2.1.2 Installation

Valves are suitable for flow in either direction,

but they should be fitted in either horizontal

pipelines with the stem upright or vertical

lines. Other positions can be detrimental to

theproper seating of the wedge.

The valves should be installed in positions

where the minimum stress is imposed on them

from expansion and contraction of the pipe, and

pipework should be adequately supported close

to the valve to minimize mechanical pipe strain.

For bolting valves into the pipeline, see General

Installation Instructions Section 1.

All valves will have been pressure tested at

ambient temperature before delivery, so it is

recommended that gland packing nuts should

be tightened after a short time on higher

temperature service.

2.1.3 Operation

Rotation of the handwheel in the clockwise

direction (see markings) will cause the valve

to close, and vice versa. Shut off should be

achieved by application of the handwheel torque

only. Excessive application of force can result in

failure of the thrust assembly or damage to the

valve seating.

PARTS LIST

No. Description

1 Body

2 Seat ring

3 Wedge gate

4 Stem

5 Bonnet bolt

6 Bonnet nut

7 Gasket

8 Bonnet

9 Backseat

10 Packing

11 Gland eyebolt

12 Gland

13 Gland flange

14 Eyebolt nut

15 Eyebolt pin

16 Nipple

17 Stem nut

18 Yoke sleeve nut

19 Hand wheel

20 Hand wheel nut

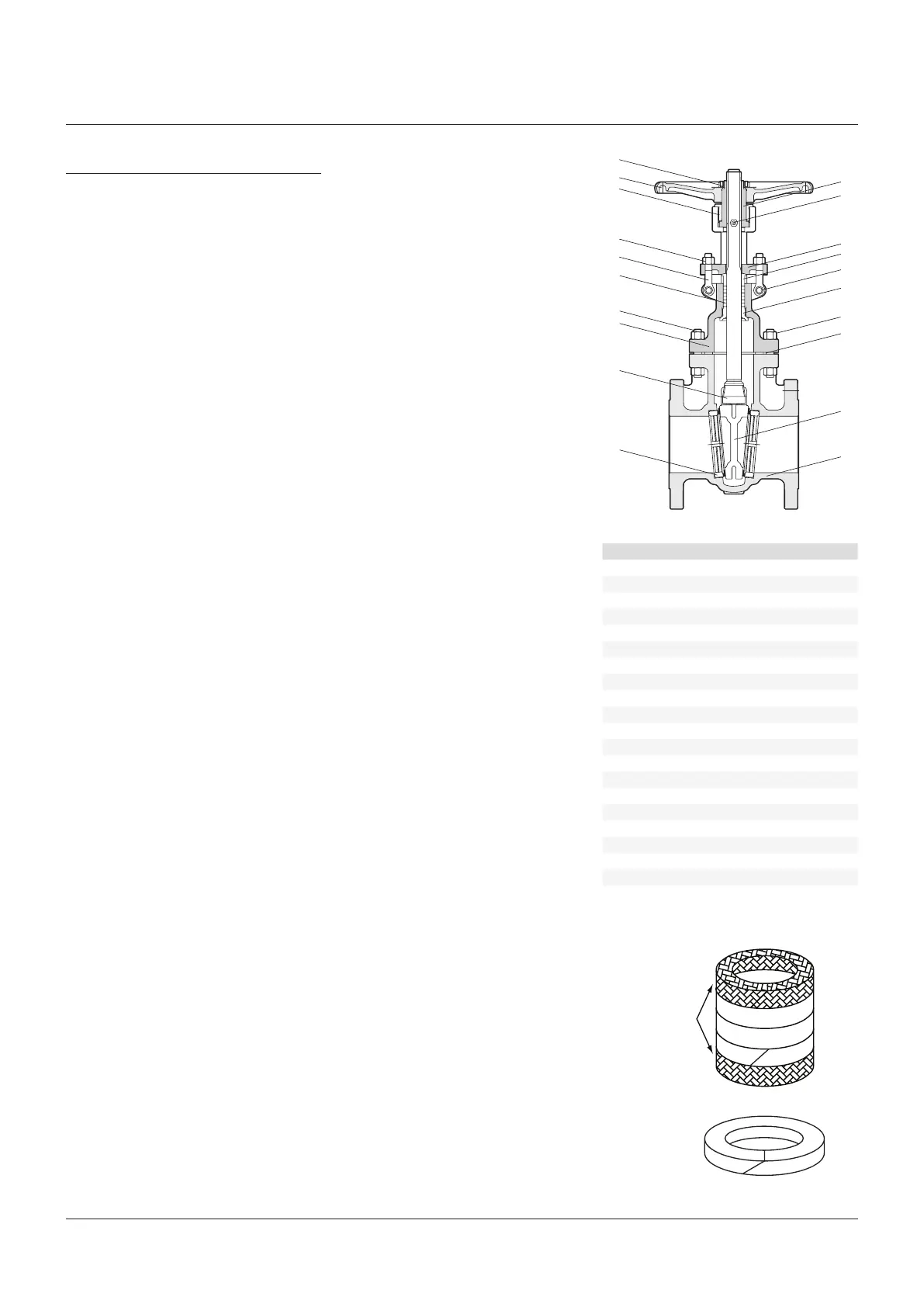

Braided end ring

Die-formed rings

(3 min.)

Braided end ring

120° Stagger of joints

45° End cut

2.2 Maintenance

Gland leakage

CAUTION

On no account should stem gland repacking be

attempted under pressure if the contained fluid is

dangerous because of temperature, high pressure

or chemical composition.

Evenly tighten the gland adjusting nuts to

compress the packing rings.

If this does not correct the leakage or if

the adjustment is fully used up, it will be

necessaryto repack the gland using a new

set of the correct grade packing, or to add

packingring(s).

Re-packing glands

To gain access to the packing box, the gland

adjusting nuts should be removed and the

gland and packing flange removed or retracted

along the stem as far as possible. When the

stuffing box has been completely emptied of the

original packing, it must be thoroughly cleaned

before the new packing is introduced. It is

recommended that the packing manufacturers

general instructions are followed when

repacking glands.

General

It is recommended that the reconditioned valve

should be subjected to hydrostatic testing in

line, before being reinstated on line working

conditions.

2.3 Spares

The normal requirement for spare parts for

normal wear in service are gland packing

andgaskets.

Loading...

Loading...