5

13

12

10

9

8

11

07

06

05

04

03

01

02

HANCOCK CAST STEEL - GATE, GLOBE AND CHECK VALVES

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

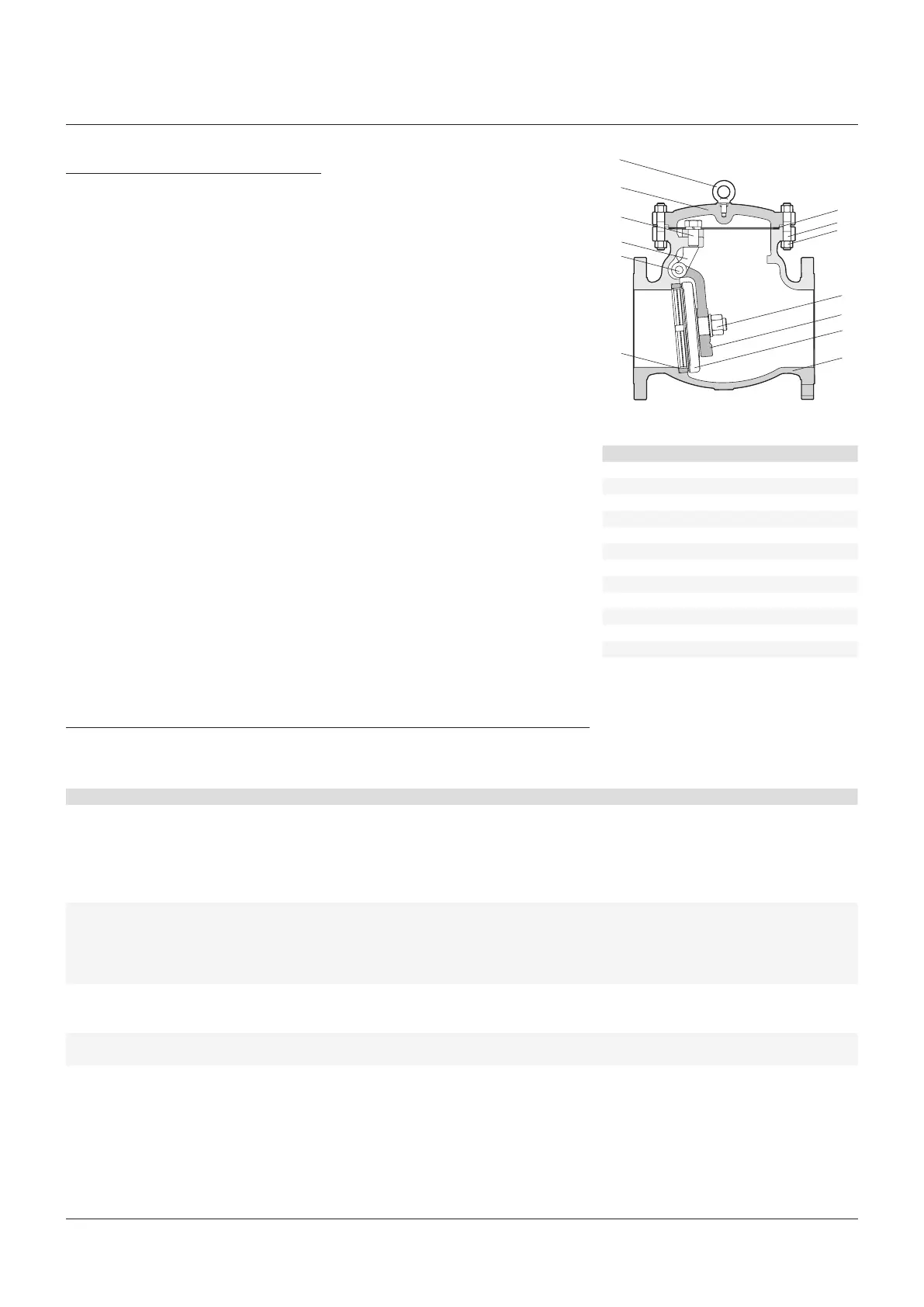

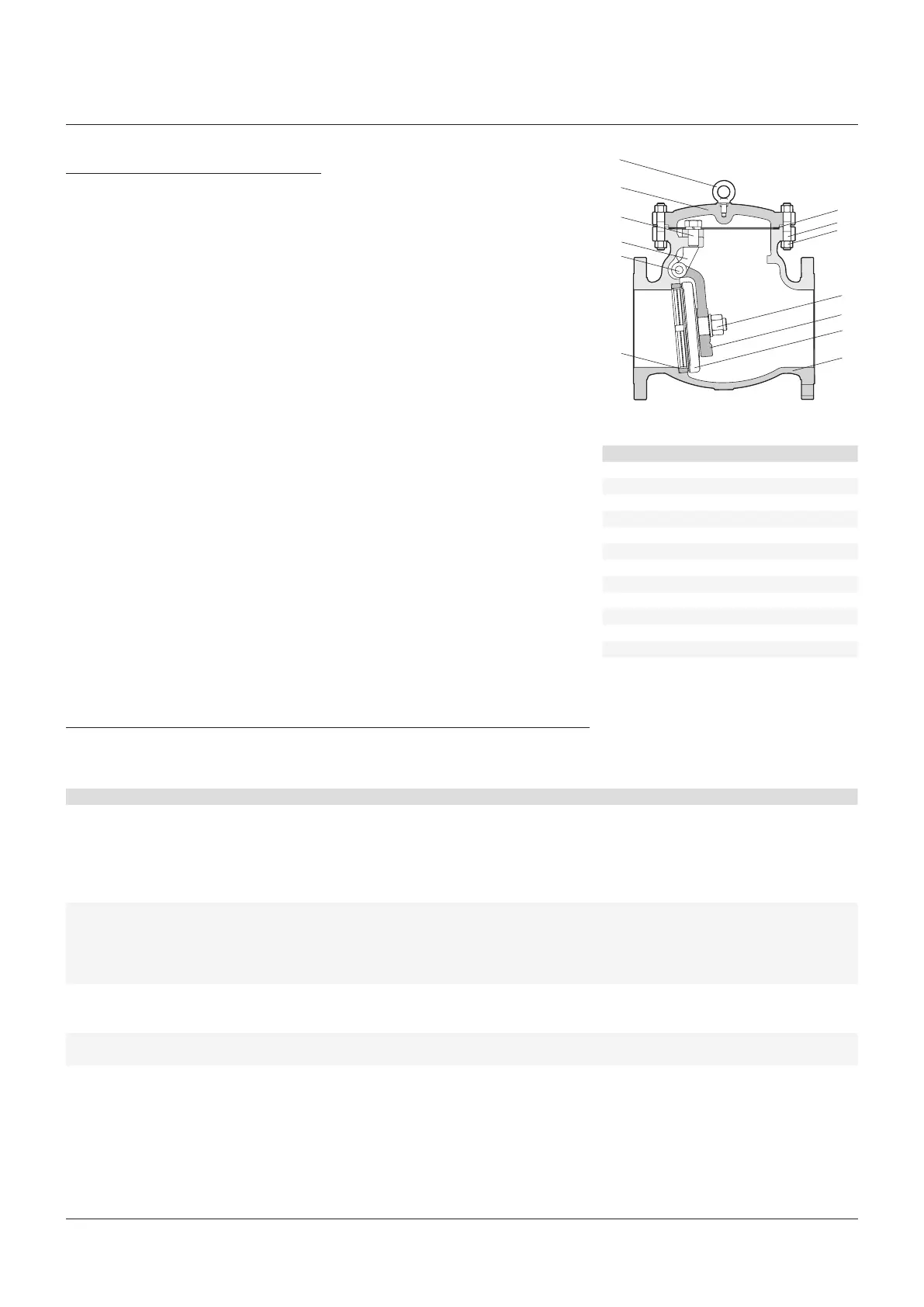

4 SWING CHECK VALVES

4.1 Installation of valve

4.1.1 Prior to installation

Valves not required for immediate use should

be stored under clean conditions to reduce the

risk of foreign matter entering the valve during

unpacking. If the valves are unpacked for

checking purposes, they should be immediately

re-packed until required for use.

Protection caps fitted to inlet and outlet

connections must be removed but not until

immediately prior to installation.

Check that the disk is swinging freely on its

hinge arrangement with no hang-ups.

Seating faces should be wiped clean with a dry

clean cloth before commencing installation.

PARTS LIST

No. Description

1 Body

2 Seat ring

3 Disc

4 Lever arm

5 Nut

6 Hinge pin

7 Yoke

8 Bonnet nut

9 Bonnet stud

10 Bolt

11 Gasket

12 Cover

13 Eye bolt

5 TROUBLE-SHOOTING

The following table will cover the various problems which are common to most valves.

Theinformation provided will aid in isolating and correcting these problems.

Problem Possible cause Solution

Leakage through

thestempacking

1. Gland nuts are loose. 1. Tighten gland bolts.

2. Gland is binding against the stem or packing chamber wall. 2. Check to ensure gland is centered and evenly tightened.

3. Inadequate amount of packing rings. 3. Install additional packing rings.

4. Packing is hard and dry. 4. Replace with new packing.

5. Packing was not properly cut and staggered. 5. Replace with new packing.

6. Stem is damaged. 6. Repair or replace as required.

Problems in operating

valve

1. Stem binding during travel. 1. Remove dirt and lubricate stem with grease.

2. Stem packing is exerting excessive force on the stem. 2. Check torque on gland nuts.

3. Stem is damaged. 3. Examine stem through full open and close action.

Repairorreplaceasrequired.

4. Internal components may be damaged. 4. Disassemble the valve. Inspect and repair as needed.

Bonnet leakage 1. Bonnet nuts are loose. 1. Tighten to values as listed.

2. Gasket is damaged. 2. Disassemble and install a new gasket.

3. Flange faces are damaged. 3. Repair and install a new gasket.

Seat leakage 1. Valve not properly seated.

1. Check to see if valve is tightly closed.

2. Internal components are damaged or worn.

2. Inspect internal components and repair as required.

4.1.2 Installation

Valves are suitable for flow in one direction only

and this is shown by a direction arrow marked

on the valve body. It is essential that they are

installed in the correct flow (arrow) situation.

They may be fitted in horizontal or vertical

(flow-upwards) pipelines, or any in-between

lines with flow-upward. They must always be

orientated so that the hinge swings downwards

and with the hinge pin horizontal.

The valves should be installed in positions

where the minimum stress is imposed on them

from expansion and contraction of the pipe,

and pipe work should be adequately supported

each side of the valve to minimize mechanical

pipestrain.

4.2 Maintenance

Routine Maintenance

While the valve is working satisfactory, there

isno requirement for servicing.

Loading...

Loading...