Safety

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

Mentor MP User Guide 69

Issue: 3 www.controltechniques.com

The output of the speed regulator is a torque demand given as a

percentage of rated motor torque. This is then modified to account for

changes in motor flux if field weakening is active, and then used as the

torque producing current reference.

The torque demand can be derived from the speed controller and/or the

torque reference and offset. The units of the torque demand are a % of

rated torque.

The current feedback signal is derived from internal current

transformers. It is used for closed loop control and indication of the

armature current, and to initiate motor protection.

Indicates the field current feedback in 0.01 amperes.

The average measured DC output voltage seen across the drive A1 and

A2 terminals or the average measured DC output voltage seen across

the motor. Selected by Pr 5.14.

The armature voltage feedback has a resolution of 10-bit plus sign.

These parameters are controlled by the drive sequencer as defined in

Menu 6. They select the appropriate reference as commanded by the

drive logic. di11 (Pr 0.46, 1.11) will be active if a run command is given,

the drive is enabled and the drive is ok. This parameter can be used as

an interlock in a Onboard PLC or SM-Applications program to show that

the drive is able to respond to a speed or torque demand.

The parameter displays the software version of the drive.

6.1.5 Trips

Contains the last 10 drive trips. tr01 (Pr 0.51, 10.20) is the most recent

trip and tr10 (Pr 0.60, 10.29) the oldest. When a new trip occurs all the

parameters move down one, the current trip is put in tr01 (Pr 0.51,

10.20) and the oldest trip is lost from the bottom of the log. Descriptions

of the trips are given in Table 13-1 on page 167. All trips are stored,

including HF trips numbered from 20 to 29. (HF trips with numbers from

1 to 16 are not stored in the trip log.) Any trip can be initiated by the

actions described or by writing the relevant trip number to Pr 10.38. If

any trips shown as user trips are initiated the trip string is "txxx", where

xxx is the trip number.

6.1.6 Speed loop

SP01 (Pr 0.61/3.10) operates in the feed-forward path of the speed-

control loop in the drive. See Figure 11-3 on page 102 for a schematic of

the speed controller. For information on setting up the speed controller

gains, refer to Chapter 8 Optimization on page 78.

SP02 (Pr 0.62, 3.11) operates in the feed-forward path of the speed-

control loop in the drive. See Figure 11-3 on page 102 for a schematic of

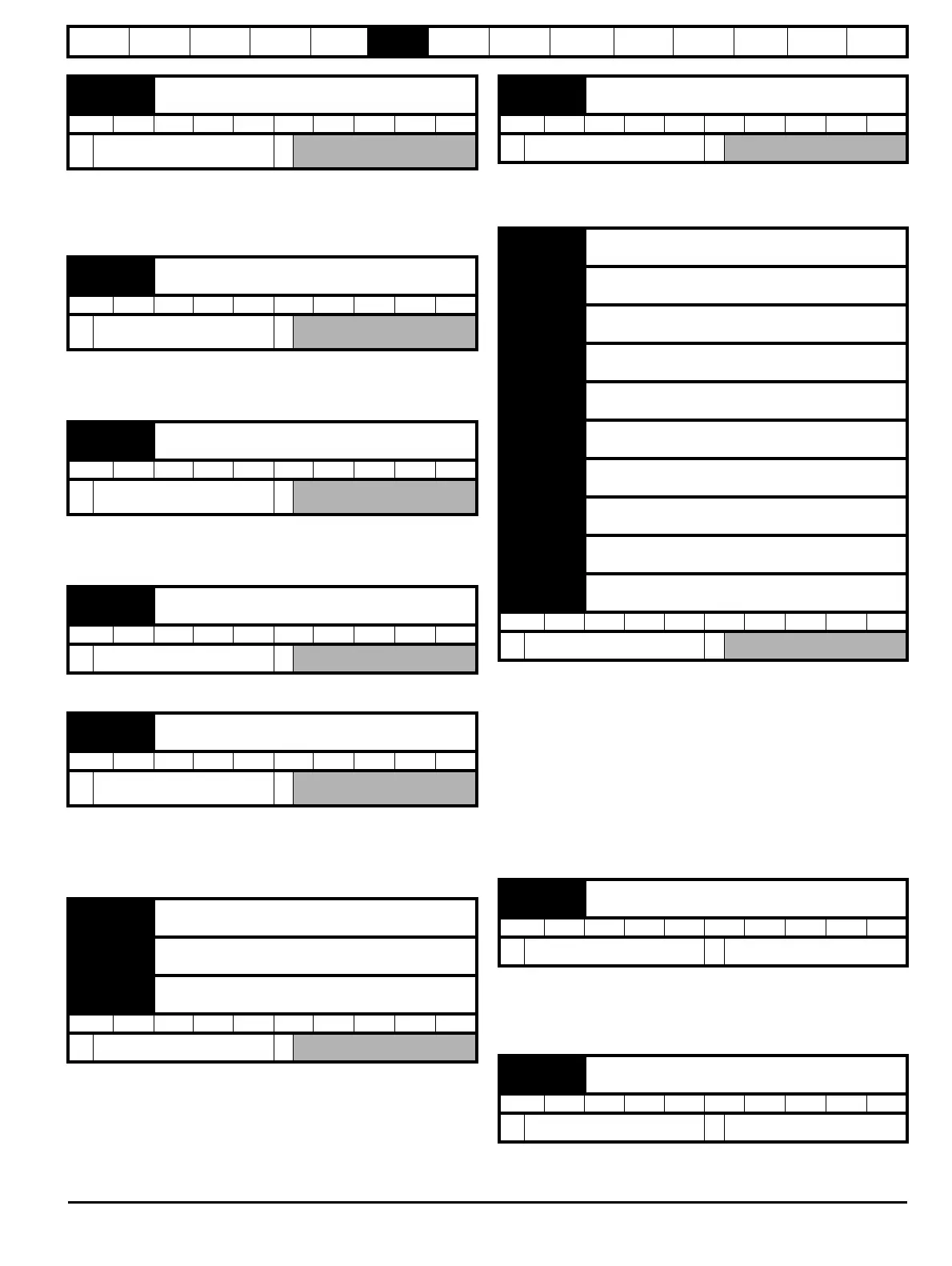

di06

{0.41, 3.04}

Speed controller output

RO Bi FI NC PT

Ú

±TORQUE_PRODUCT_

CURRENT_MAX rpm

Ö

di07

{0.42, 4.03}

Torque demand

RO Bi FI NC PT

Ú

±TORQUE_PROD_

CURRENT_MAX %

Ö

di08

{0.43, 4.01}

Current magnitude

RO Uni FI NC PT

Ú

0 to DRIVE_CURRENT_MAX

A

Ö

di09

{0.44, 5.56}

Field current feedback

RO Bi FI NC PT

Ú

±50.00A

Ö

di10

{0.45, 5.02}

Armature voltage

RO Bi FI NC PT

Ú

±ARMATURE_VOLTAGE_

MAX V

Ö

di11

{0.46, 1.11}

Reference enabled indicator

di12

{0.47, 1.13}

Reverse selected indicator

di13

{0.48, 1.14}

Jog selected indicator

RO Bit NC PT

Ú

OFF (0) or On (1)

Ö

di14

{0.49, 11.29}

Software version

RO Uni NC PT

Ú

1.00 to 99.99

Ö

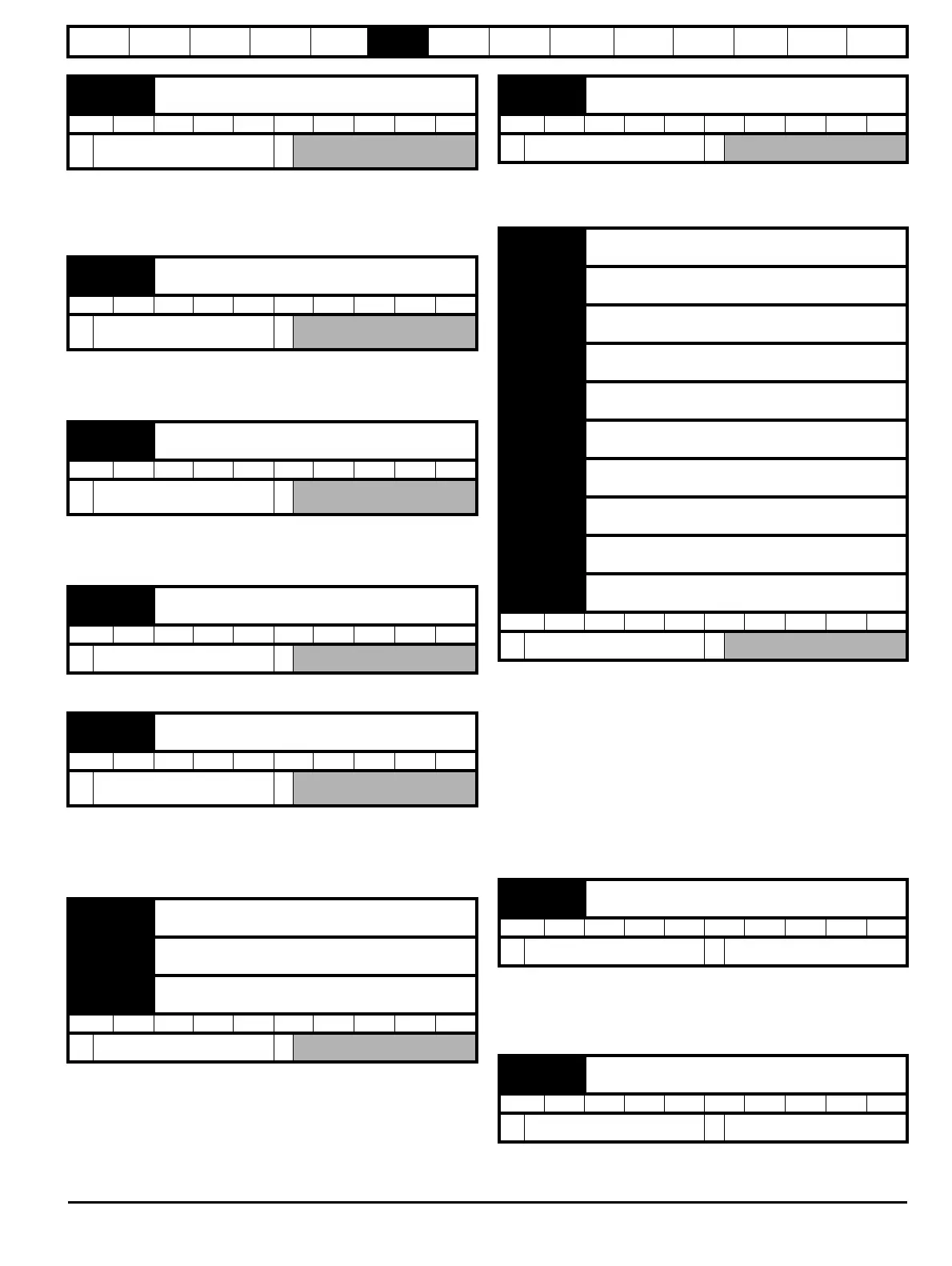

tr01

{0.51, 10.20}

Trip 0

tr02

{0.52, 10.21}

Trip 1

tr03

{0.53, 10.22}

Trip 2

tr04

{0.54, 10.23}

Trip 3

tr05

{0.55, 10.24}

Trip 4

tr06

{0.56, 10.25}

Trip 5

tr07

{0.57, 10.26}

Trip 6

tr08

{0.58, 10.27}

Trip 7

tr09

{0.59, 10.28}

Trip 8

tr10

{0.60, 10.29}

Trip 9

RO Txt NC PT PS

Ú

0 to 229

Ö

SP01

{0.61, 3.10}

(Kp1) Speed controller proportional gains

RW Uni US

Ú

0.0000 to 6.5535 (1 / (rad/s))

Ö

0.0300

SP02

{0.62, 3.11}

(Ki1) Speed controller integral gains

RW Uni US

Ú

0.00 to 655.35 (s / (rad/s))

Ö

0.1

Loading...

Loading...