3

OVERPRESSURE PROTECTION

The recommended safety pressure limitations are stamped

on the valve label.

Downstream overpressure protection shall be also provided

if the inlet pressure can be greater than the PS (see label).

Equipment’s operation below the maximum pressure

limitations does not preclude the possibility of damage from

external sources or debris in the line.

The relief valve should be inspected for damage after any

overpressure condition.

TRANSPORT AND HANDLING

Established transport and handling procedures shall be

followed to avoid any damage on the pressure containing

parts by shocks or anomalous stresses.

Ringbolts are designed just for handling of equipment

weight.

Built-up sensing lines and pressure accessories (e.g. pilots)

shall to be protected by shocks or anomalous stresses.

ATEX REQUIREMENTS

If the provisions of EN 12186 & EN 12279, national

regulations, if any, and specic manufacturer

recommendations are not put into practice before

installation and if purge by inert gas is not carried out before

equipment’s start-up and shut-down operations, a potential

external and internal explosive atmosphere can be present

in equipment & gas pressure regulating/measuring stations/

installations.

If a presence of foreign material in the pipelines is foreseen

and purge by inert gas is not carried out, the following

procedure is recommended to avoid any possible external

ignition source inside the equipment due to mechanical

generated sparks:

• drainage to safe area via drain lines of foreign materials, if

any, by inow of fuel gas with low velocity in the pipe-work

(5m/sec)

In any case,

• provisions of Directive 1999/92/EC and 89/655/EC shall

be enforced by gas pressure regulating/measuring station/

installation’s end user

• with a view to preventing and providing protection against

explosions, technical and/or organizational measures

appropriate to the nature of the operation shall be taken

(e.g. : lling/exhausting of fuel gas of internal volume

of the isolated part/entire installation with vent lines

to safe area - 7.5.2 of EN 12186 & 7.4 of EN 12279 ;

monitoring of settings with further exhaust of fuel gas to

safe area ; connection of isolated part/entire installation to

downstream pipeline; ….)

• provision in 9.3 of EN 12186 & 12279 shall be enforced

by pressure regulating/measuring station/installation’s end

user

• external tightness test shall be carried out after each

reassembly at installation site using testing pressure in

accordance with national rules

• periodical check/maintenance for surveillance shall be

carried out complying with national regulations, if any, and

specic manufacturer recommendations.

OPERATION

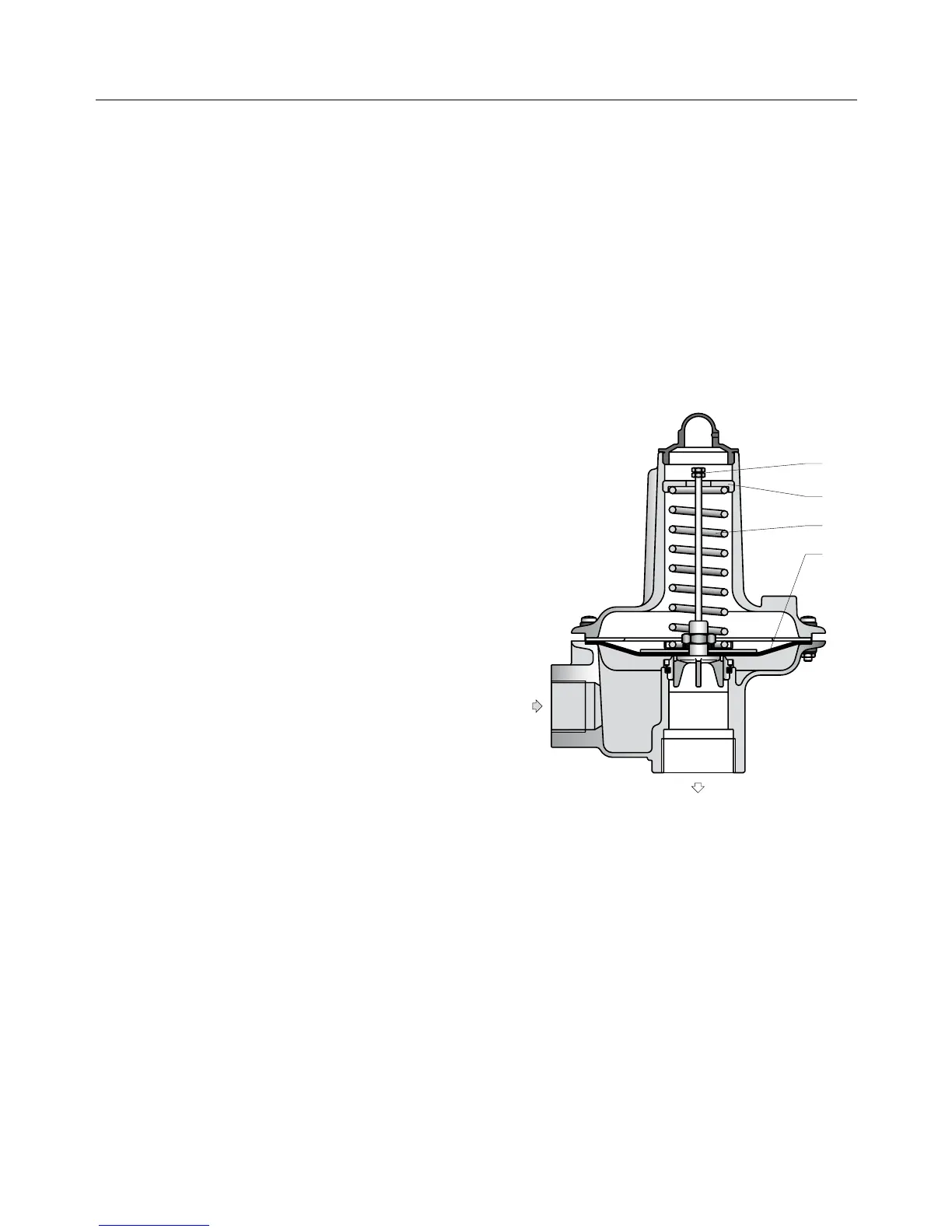

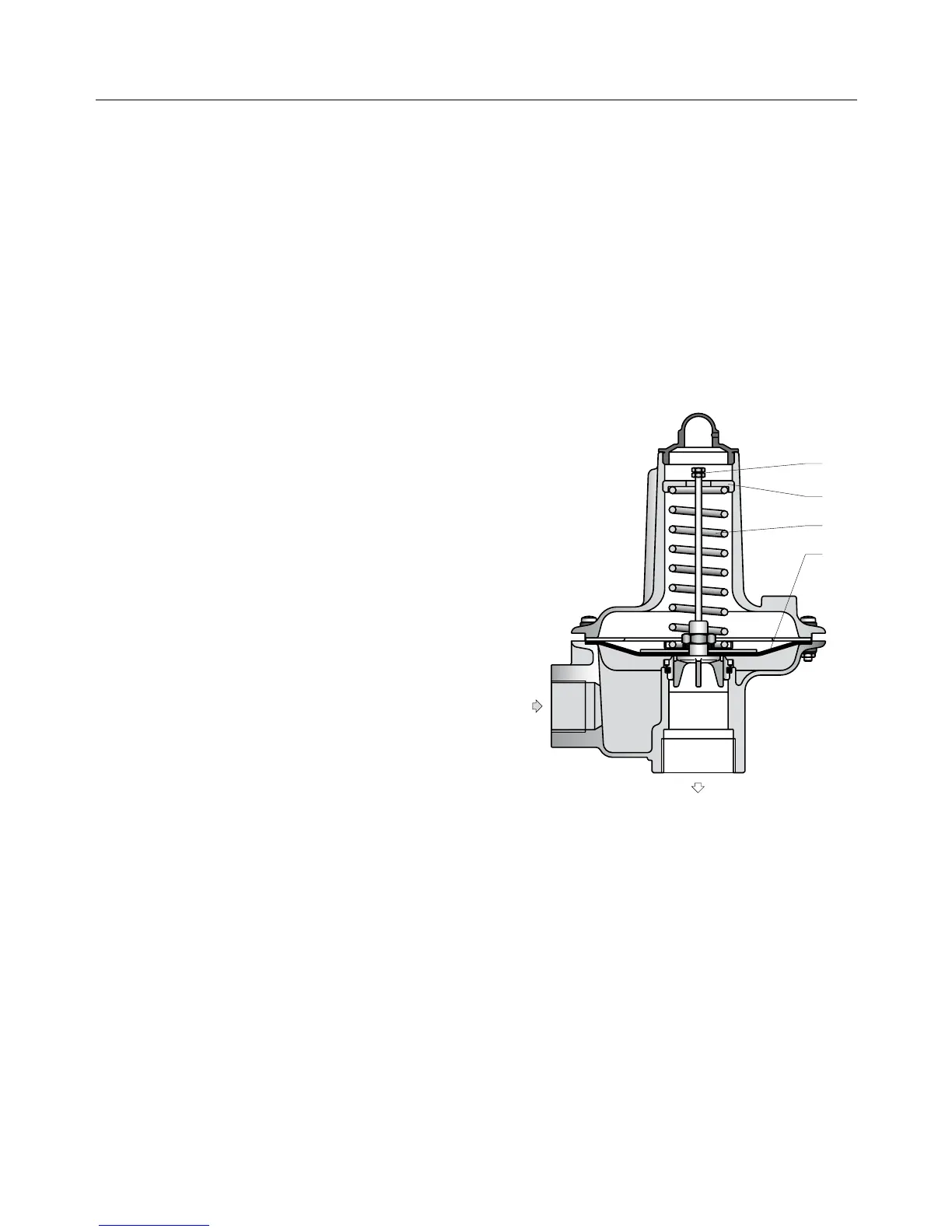

V/50 and V/60 Series

Figure 3. Closed V/50 Relief Valve

Whenever gas pressure under diaphragm (D) is higher than

the force exerted by spring (M), diaphragm is raised causing

sleeve (O), which is integral with the diaphragm itself, to

move and thereby open the release orice.

In order to check the efciency of the relief valve, pull up

valve opening stem (S).

Valve setting is carried out by adjusting the compression of

spring (M) through the appropriate ring (G).

Valve set point should generally be at an intermediate value

between active regulator or monitor and slam-shut valve

(if tted) set points.

In all other cases, it is recommended that relief valve be set

at a value at least 15% higher than the working pressure of

the equipment.

Loading...

Loading...