Prosonic S FDU90/91/91F/92/93/95/96

Endress + Hauser 11

Installation conditions for

level measurements

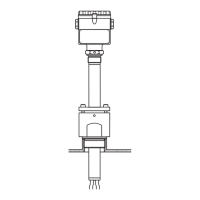

L00-FDU9xxxx-17-00-00-xx-003

• If possible, install the sensor so that its lower edge projects into the vessel.

• Make sure, that the maximum level does not reach into the blocking distance (BD, see table).

• Do not install the sensor in the middle of the tank (2). We recommend leaving a distance (1) between the

sensor and the tank wall measuring 1/6 of the tank diameter.

• Avoid measurements through the filling curtain (3).

• Make sure that equipment (4) such as limit switches, temperature sensors, baffles etc. are not located within

the emitting angle α. Emitting angles of the individual sensors are given in the table below. In particular,

symmetrical equipment (5) such as heating coils etc. can influence the measurement.

• Align the sensor vertically to the product surface (6). An alignment unit (FAU40) is available as an accessory

(see chapter "Accessories").

• If the two-channel version of the transmitter FMU90 is used, both sensors can be mounted in one vessel.

• To estimate the detection range, use the 3 dB emitting angle α:

#

Warning!

All national guidelines applicable must be observed in explosion hazardous areas.

1

2

3

4

5

1/6D

D

r

α

L

BD

BD

6

BD

Sensor Blocking distance BD α (typically) Application L (max) r (max)

FDU90 0.07 m 12°

fluids 3 m 0.31 m

bulk materials 1.2 m 0.13 m

FDU91 0.3 m 9°

fluids 10 m 0.79 m

bulk materials 5 m 0.39 m

FDU91F 0.3 m 12°

fluids 10 m 1.05 m

bulk materials 5 m 0.53 m

FDU92 0.4 m 11°

fluids 20 m 1.92 m

bulk materials 10 m 0.96 m

FDU93 0.6 m 4°

fluids 25 m 0.87 m

bulk materials 15 m 0.52 m

FDU95 • 0.7 m (low temperature version)

• 0.9 m (high temperature version)

5° bulk materials 45 m 1.96 m

FDU96 1.6 m 6° bulk materials 70 m 3.6 m

Loading...

Loading...