Frontier Oil Heat – PN 10-2021 – October 2021 - 13 -

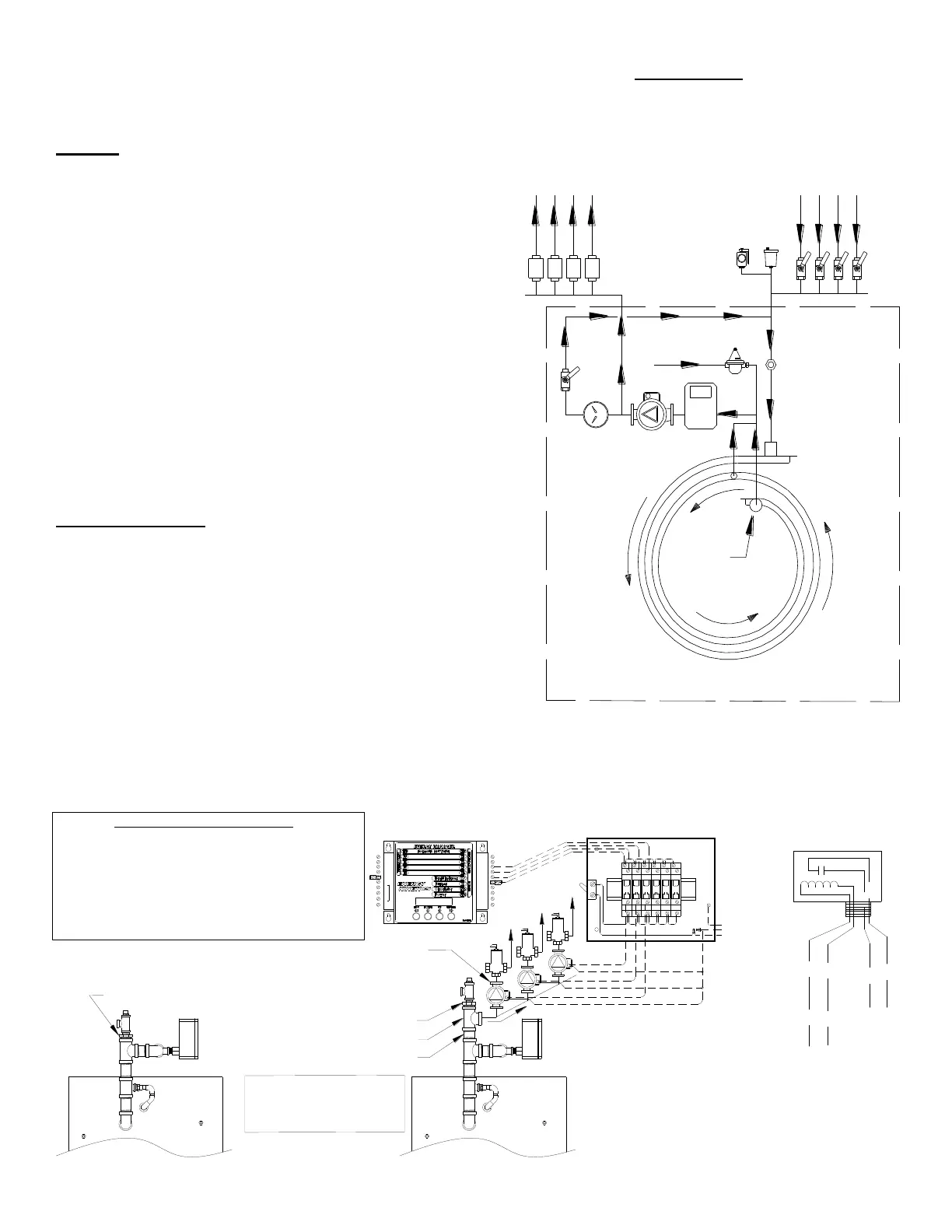

Supply

Return

Return

Supply

Boiler Feed

Energy Converter

Typical Flow

Schematic

Factory piping shown within dashed line

Supply

Boiler Bypass

Digital

Sensor

BOILER PITCH: The Frontier pressure vessel is manufactured with the rear ½ to 1 bubble higher to allow for proper air

removal. This pitch is carefully set at the factory when the boiler is built. Be sure to level the stand prior to mounting the

boiler on the stand. When the stand is level, the pitch is correct and the back of the boiler will be higher than the front.

The EK1 Frontier is pitched 1/4" and the EK2 Frontier is pitched 7/16".

PIPING

All piping and accessory connections should follow good

practice using approved joint sealants.

Figure 2C indicates a typical flow schematic for boiler water

feeding multiple zones. Each system will vary according to

job location.

Supply and return connections are 1”NPT on the EK1 and 1-

1/4”NPT on the EK2.

Call Energy Kinetics to obtain piping and wiring instructions

for alternate applications, such as hydronic heating, radiant

heating, domestic hot water, swimming pool heating, multiple

boilers, injection loops, etc.

Figures 2A and 2B indicate general system piping

arrangement and options. Piping of individual systems may

vary from Figures.

ZONE CONTROL

ZONE CONTROL BY VALVE: The SYSTEM 2000 Boiler is

designed to provide multi-zone control of the heating system and

optionally can supply domestic hot water. Energy Kinetics

recommends and supplies two wire, full port, 24-volt zone valves for

control of each heating zone. A system with a single heating zone

still requires a zone valve to provide control for preheat of unit and

to maintain minimum temperature during operation.

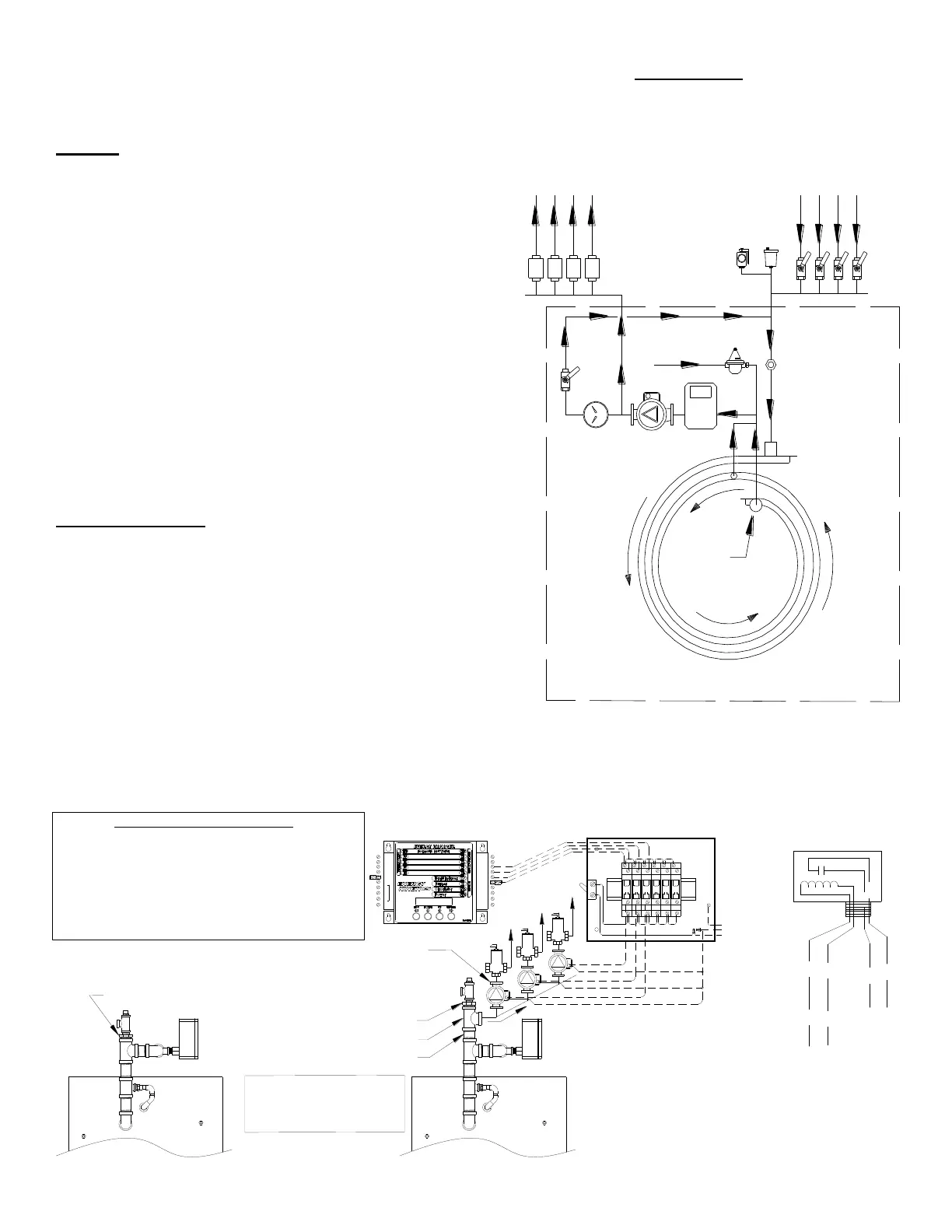

ZONE CONTROL BY CIRCULATOR: Zone control by circulators

requires a flow valve, circulator and 24-volt relay (Multi relay kits or

Individual relays such as a RIB relay available from Energy Kinetics)

for each zone. The main circulator and boiler bypass line are still used in these cases. NOTICE: An additional tee must

be installed into the supply on the inlet side of the main circulator. This tee is the supply for circulators with returns for

these zones into normal return location. Call Energy Kinetics and request “Zoning with Circulators” diagram.

ORANGE

YELLOW

WHITE / YELLOW

WHITE/BLUE

EK# 10-0412-RIB (RIB# 2421C)

24V/120VAC Relay SPDT

24VAC

Coil Leads

To Manager,

Zx & 24V

N/O Contact

Leads

To CIRC,

Power To L1

Full Size Tee (added)

Nipple (added)

Bushing (moved)

1. Remove bushing installed at

factory from boiler supply.

2. Install a nipple (not supplied)

into the existing tee.

3. Install a tee (not supplies) on

to the new nipple.

4. Reinstall the bushing into the

new tee.

SUPPLY

Ground

Neutral

Line

120 VAC

Frontier Boiler Supply Piping

Modified piping for Zone

Circulators.

Looking from rear of boiler.

Circulators w/IFC or Circulators and Flow Checks

(Supply Side Preferred*)

*Circulator may be Installed Return Side

System Manager

5 Zone Circulator Relay Kit

P/N: 10-0412R-5 Shown

ZONE CIRCULATOR RELAY KITS

TO ACTIVATE EACH CIRCULATOR, USING The

SYSTEM MANAGER'S 24VAC OUTPUTS, USE ONE OF

ENERGY KINETICS MULTIPLE ZONE RELAY KITS.

5 ZONE RELAY KIT P/N: 10-0412R-5

10 ZONE RELAY KIT P/N: 10-0412R-10

15 ZONE RELAY KIT P/N: 10-0412R-15

OR INDIVIDUAL 24V RELAY(S) (EK#10-0412-RIB RIB

RELAY OR EQUIVALENT)

Bushing (Installed at Factory)

TEMP. SENS.

R

S

B

A2

A1

B2

CIRC

B1

24VAC

IND

T3

T1

T2

THW

T4

Z1

Z2

Z3

Z4

ZHW

Loading...

Loading...