PRO 32 & 48 X-AXIS ASSEMBLY

19

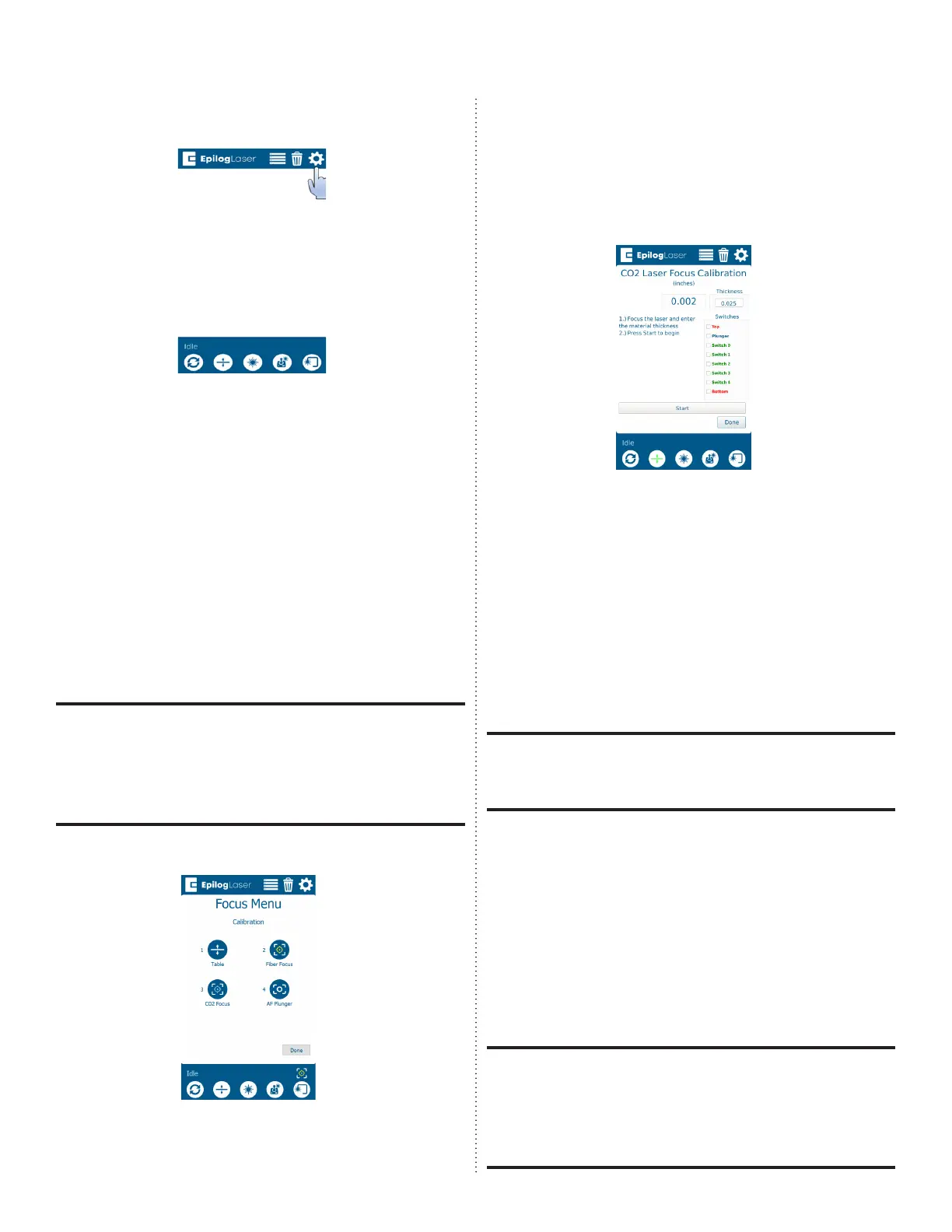

11. On the display, press the gear icon to

enter the Settings menu:

12. Ensure that the material thickness used

during the previous step is entered in

the Thickness box. If using anodized

aluminum provided by Epilog Laser, the

default value of 0.025” corresponds to

the material.

13. Press the Start button. This calibration is

very fast as the engraver simply notes

and saves the current position of the

table.

14. Press Done.

The CO2 focus must be set to the same

height as the fiber focus before moving

onto the CO2 Focus Calibration. Failure to

complete this step will result in an inaccu-

rate focus calibration.

15. Press the CO2 Focus button:

16. Ensure that the material thickness used

during the previous step is entered in

the Thickness box. If using anodized

aluminum provided by Epilog Laser, the

default value of 0.025” corresponds to

the material.

17. Press Done.

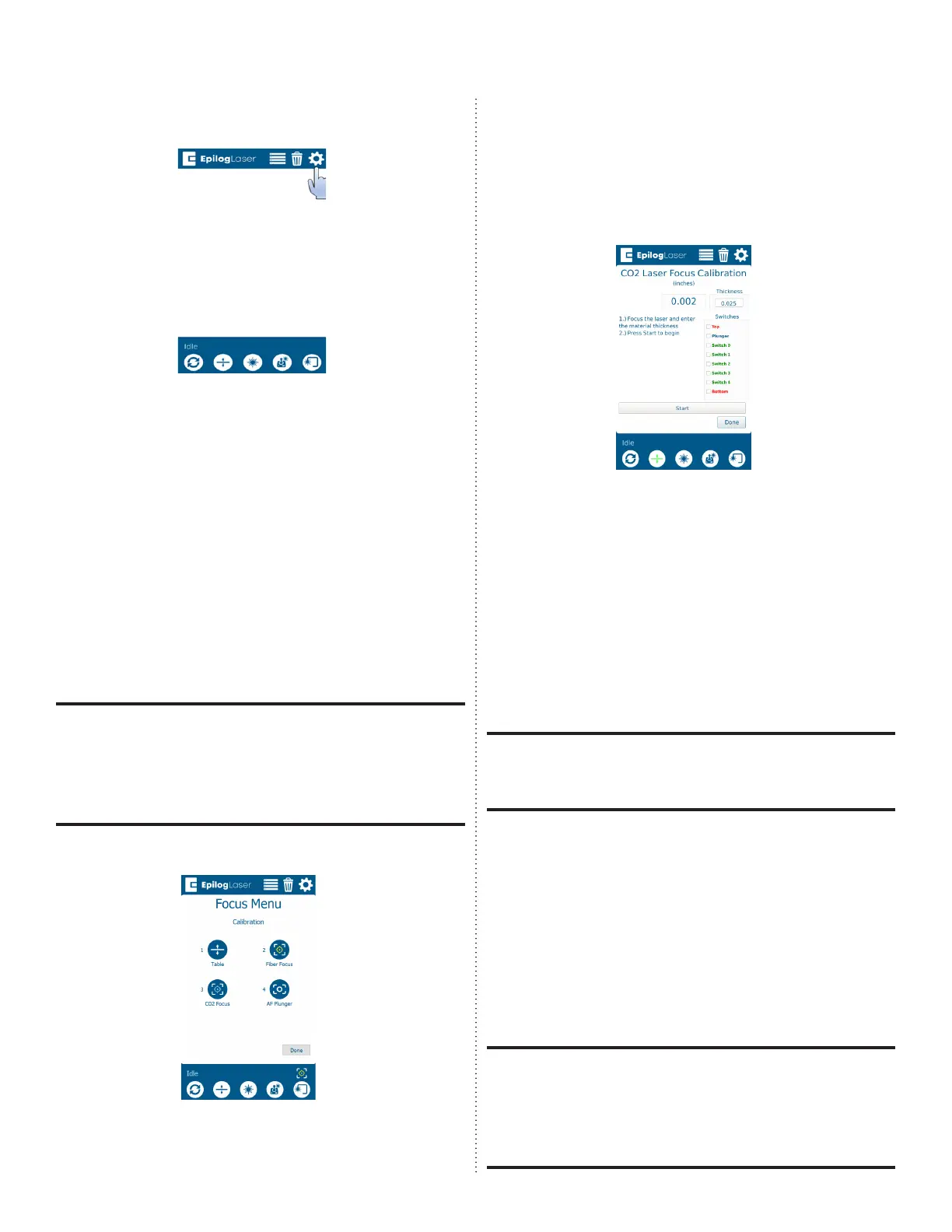

CO2 Focus Calibration

The CO2 focus calibration establishes

the focal height of the laser and manual

focus gauge. You will run a small job while

adjusting the table height to find the

correct focal height.

A small piece of anodized aluminum (at

least 3” x 3” or 75mm x 75mm) is required to

complete this procedure.

1. Open your preferred illustrating

program and create a black, raster box

measuring ~2” x 2” or 50mm x 50mm.

2. Send the job to the Soware Suite.

3. Ensure that the process shows as an

engraving job and set the both power

and speed at 5-10%.

If completing the procedure on the Fusion

Pro 32, place the artwork and material

in the upper le corner of the engraving

table, ensuring that the artwork appears

over the anodized aluminum.

Loading...

Loading...