Safety and operating instructions

© Construction Tools GmbH | 3390 5149 01 | 2020-09-22

Original Instructions

17

LED 4

LED 5

LED 6

LEDs 4, 5 and 6 flash simultaneously

Insulation fault detected

If an insulation fault is detected, a restart

is automatically blocked. The Hydro

Magnet cannot be switched on again.

This is a safety risk! Lethal contact

voltages can occur on metal parts!

Contact a qualified electrician immedi-

ately.

LED 4

LED 5

LED 6

LEDs 4, 5 and 6 light up simultaneously

and 100% flashes

Pre-alarm over temperature of the con-

trol electronics

Although the generator system is de-

signed for continuous operation, it may

be too hot in some special cases. This

risk exists when at full load, if the cool-

ing of the generator and the control

electronics is disabled or if the tempera-

ture of the cooling air exceeds the maxi-

mum allowable value of 40°C (104°F).

Warning temperature of control electron-

ics

The temperature in the control electron-

ics, has exceeded the pre-alarm limit

value. The generator system is blocked

from restarting until the temperature has

decreased in the control electronics

again and overtemperature - advance

warning goes out. If the generator sys-

tem is still used despite an overtempera-

ture - advance warning under load, the

temperature will continue to rise, and af-

ter about 10 minutes an immediate shut-

down of the system will occur due to ex-

ceeded temperature limit.

LED 4

LED 5

LED 6

LEDs 4, 5 and 6 and 100% flash

Temperature exceeded control electron-

ics

The temperature in the control electron-

ics has exceeded the allowed limit, and

the system is switched off immediately

without warning. Lifted loads may be

dropped from the magnet plate. After

the automatic shutdown of the system, a

lock-prevention prohibits switching on

the magnet plate again as long as it

takes the temperature of the control

electronics to fall below the warning

temperature.

Note: Newer systems report a tempera-

ture overshoot as system failure (LED 5

flashes). In newer systems, the control

electronics will not shut off the magnets

for safety reasons. However, this mes-

sage MUST ALWAYS be considered the

most critical operating point!

3.2 Function

The operation of a Hydro Magnet is described in a

greatly simplified version below:

The pressure line »P« supplies oil at the operating pres-

sure of the carrier to the generator of the Hydro Magnet.

The tank line »T« returns the oil to the tank of the carrier.

The generator generates the energy for the Hydro Mag-

net. The control electronics are attached to the genera-

tor. This is connected with the display.

The Hydro Magnet is operated by a manual or foot con-

trol in the driver's cab of the carrier. The operating condi-

tions of the system are controlled on the display.

Lift load (switch-on magnet plate)

After switching on, the generator outputs a voltage for

magnetizing the magnet plate. When you first switch on

after the start of the system, the current flowing in the

magnet plate increases relatively slowly until the rated

current is reached. The nominal voltage at the magnet

plate is then about 230V.

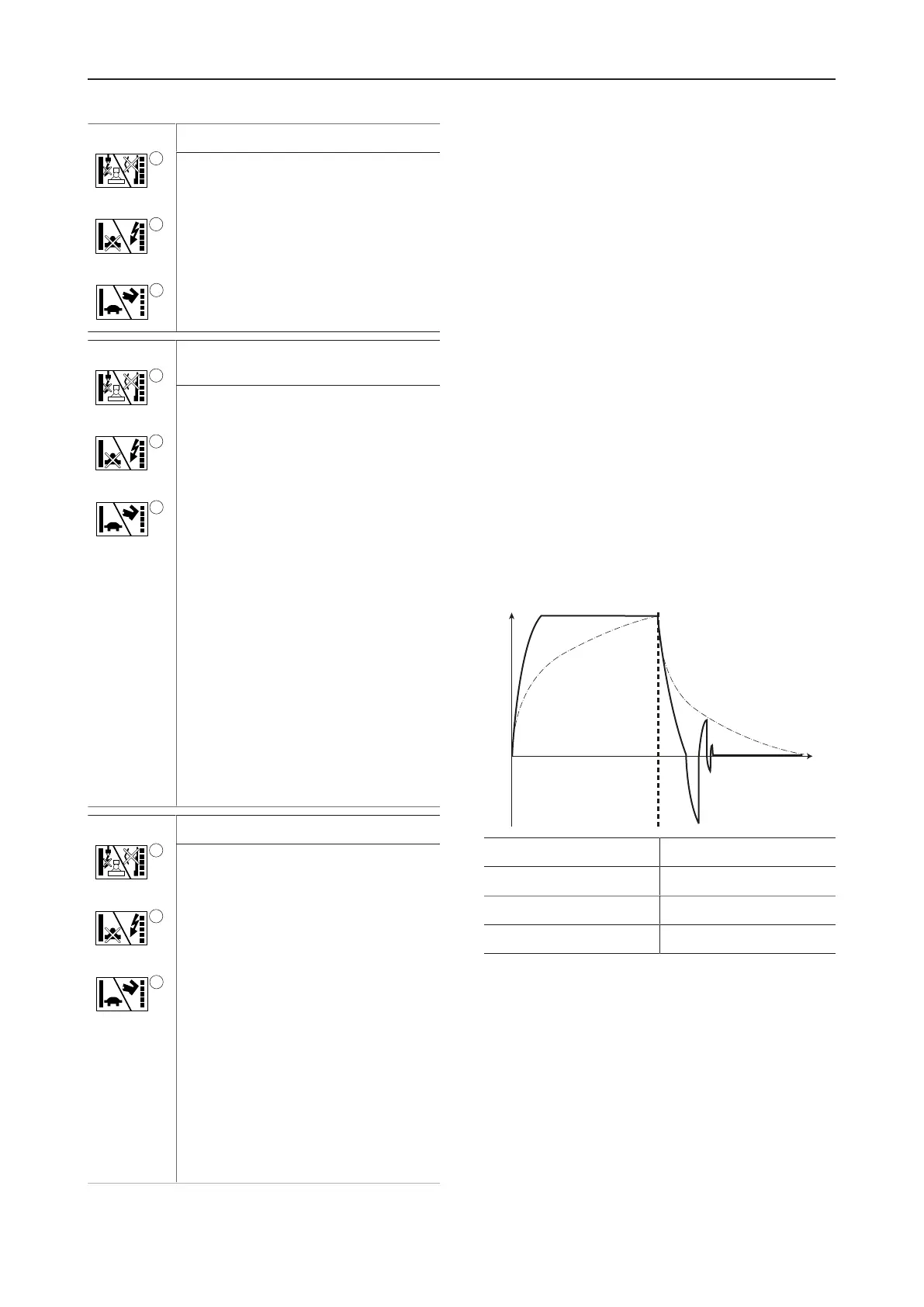

This process is illustrated in the following drawing as a

dashed curve.

1 Magnetization

2 Demagnetization

x Time

y Magnetic tractive force

In this graph it can be seen that it takes a relatively long

time for the magnet plate to reach its maximum magnetic

tractive force to lift a load. To speed up this relatively

slow magnetization, the Hydro Magnet uses a quick im-

pulse excitation method for all the following magnetiza-

tion processes. The quick magnetization with impulse

excitation is shown in the figure as a black curve.

Drop load (switch-off magnet plate)

Loading...

Loading...