Do you have a question about the ESAB Feed 3004 and is the answer not in the manual?

Explains the meaning of danger, warning, and caution symbols used in the manual.

Outlines essential safety measures for protecting oneself and others during welding operations.

Details precautions to prevent fires and explosions caused by welding operations.

Explains the hazards of electrical shock and necessary precautions to avoid it.

Discusses potential health risks associated with electric and magnetic fields during welding.

Highlights the dangers of fumes and gases and necessary ventilation measures.

Provides safety guidelines for handling compressed gas cylinders.

Warns about injuries from moving parts like fans and belts and how to avoid them.

Emphasizes the importance of proper maintenance for safe operation and avoiding hazards.

Defines the user's ultimate responsibility for ensuring safe operation and compliance with regulations.

Details risks from arc rays and necessary eye and skin protection measures.

Warns about noise hazards and the need for hearing protection.

Warns about fire hazards from sparks and hot materials, and precautions to take.

Lists the items included with the wire feed unit upon delivery.

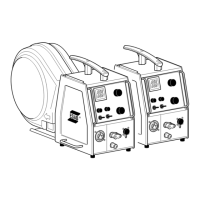

Describes the different control panel options available for the wire feed unit.

Explains how duty cycle is measured and its validity conditions.

Defines the meaning of enclosure class (IP code) and its implications for use.

Provides essential safety and procedural guidance for lifting the equipment.

Details the various connections and control devices on the wire feeder unit.

Explains the water connection system and its detection mechanism.

Guides on setting the correct wire feed pressure for smooth operation.

Step-by-step instructions for replacing or inserting welding wire.

Provides instructions on how to change the feed rollers for different wire types.

Outlines procedures for regular inspection and cleaning of the wire feed unit.

Explains how to adjust the braking torque of the wire feed hub.

Advises on cleaning and replacing wear parts of the welding torch.

Provides specific recommendations for welding with aluminium wire.

| Input Frequency | 50/60 Hz |

|---|---|

| Weight | 15 kg |

| Max. Spool Diameter | 300 mm |

| Input Voltage | 42 V |

| Wire Diameter | 0.6-1.6 mm |

| Feed Speed Range | 0.8-25 m/min |