21

Before making electrical input connections to the weld-

ing machine, “Machinery Lockout Procedures” must be

employed. If the connections are to be made from a line

disconnect switch, the switch must be padlocked in the

o position. If the connection is made from a fusebox,

remove the fuses from the box and padlock the cover

in the closed position. If locking facilities are not avail-

able, attach a red tag to the line disconnect switch (or

fuse box) to warn others that the circuit is being worked

on. If the plug-cap is used, (see 3.2B) remove plug from

receptacle.

3.2.1 Input Electrical Requirements

Models of this welding machine are designed to be oper-

ated from 208/230, or 208/230/380/400/460/575 volts single

phase 50/60 Hz, depending on model. The primary input

voltage requirements are shown on the welding machine

nameplate.

3.2.2 Input Conductor Connections

The input power cord on 208/230 Volts primary input model

is provided with an attachment plugcap. The plugcap will

mate with a standard 250 Volts, 50 Ampere receptacle

conforming to NEMA 6-50 R conguration.

The 208-575 volt primary input model must be wired to a

separately fused disconnect or circuit breaker of the size

listed in Table 3.1. This disconnect or breaker can be wired

to a single phase system or to two conductors of a three

phase system. A third conductor for grounding must also be

connected between the disconnect and the receptacle.

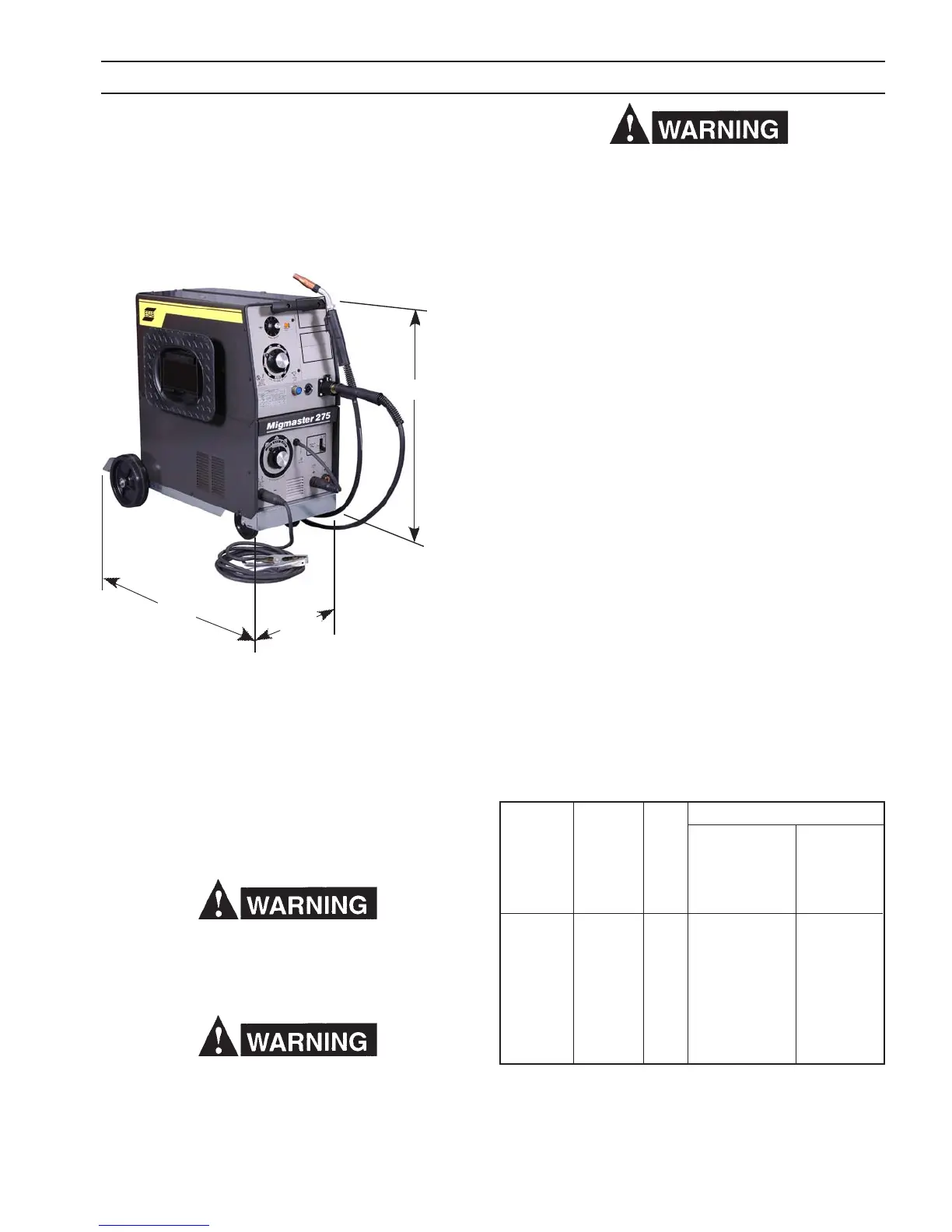

3.1 LOCATION (Figure 3.1)

Proper installation permits free air movement into and out

of the unit and minimizes exposure to dust, dirt, moisture,

and corrosive vapors. A minimum of 18 inches (46 cm)

unrestricted space must be maintained between the rear

panel and the nearest obstruction.

32.25"

19.50"

40.00"

CAUTION: Do not place any ltering device over the

air intake passages of the unit. This would

restrict air intake and cause an overheating

condition and possible failure. Warranty is

void if any type of ltering device is used.

If a forklift vehicle is used for lifting the unit, be sure that

the lift forks are long enough to extend completely under

the base.

Do not operate the machine without the running gear

installed.

3.2 ELECTRICAL INPUT CONNECTIONS

A line disconnect switch must be installed in the input circuit

to the welding machine. This is to provide a safe means to

completely remove all electrical power from the welding

machine whenever it is necessary to perform service on the

unit. (See Figure 3.2A.)

SECTION 3 INSTALLATION

Figure 3.1 Dimensions

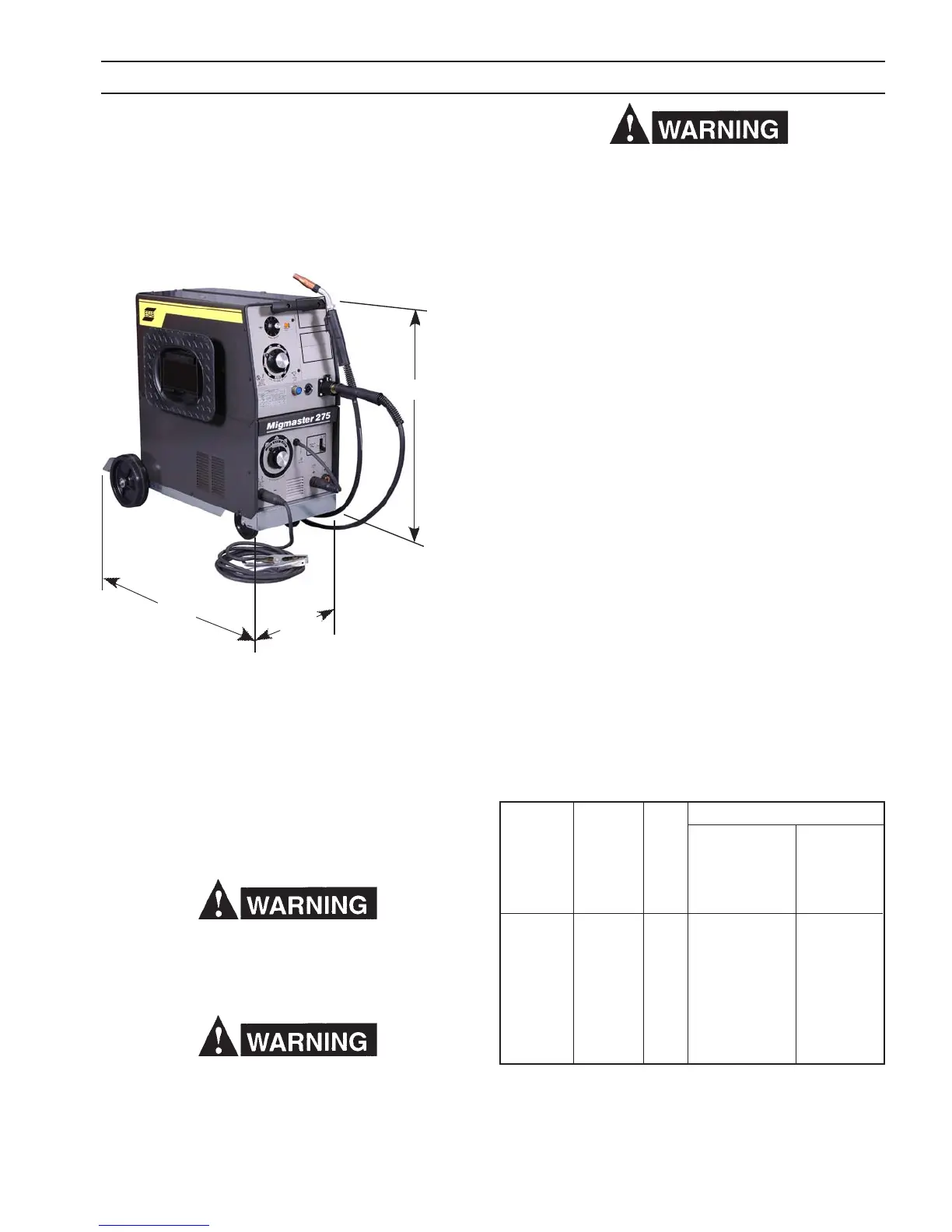

Recommended

Full Primary

Primary Load Input Ground

Input Line Fuse Conductor Conductor

Volts Amperes Size Size Size

208 66 90 6 8

230 61 80 8 8

380 37 50 10 10

380 (50Hz) 38 50 10 10

400 36 50 10 10

400 (50Hz) 36 50 10 10

460 30 40 12 12

575 25 35 12 12

TABLE 3.1 Input Conductor and Fuse Size

OPTIONAL

DIGITAL METER

MODULE

OPTIONAL

BURN BACK

MODULE

Loading...

Loading...