Why does my ESAB Welding System produce a stringy irregular bead with poor penetration?

- AAmy TylerSep 12, 2025

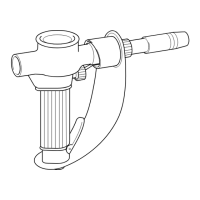

If you're experiencing a stringy or irregular bead with poor penetration while using your ESAB Welding System, here are a few things to check: * Ensure all welding cable connections are secure, as a loose connection can cause this issue. * The problem might be that the controls are not set properly for the metal gauge thickness, so try resetting the controls properly. * Double-check that you're using the correct polarity. * If the torch is moved too fast, slow down the torch movement along the seams. * Also, a malfunctioning capacitor bank could be the cause; inspect the capacitors for low leakage resistance.