30

The FINE VOLTAGE ADJUSTMENT Selector is an eight-

position switch by which the operator selects the exact

amount of arc voltage (or heat) to be applied to the weld

(within the coarse range selected above). This allows you

to ne-tune the voltage required; the higher the number

selected (1-8), the hotter the weld. The Fine Voltage Selector

switch also has an "open" detent at the six o'clock position.

Placing the switch in this position allows operation of the

torch trigger to feed electrode wire without the wire being

electrically "hot". This switch also, must not be switched

under load.

These tap switches carry several hundred am-

peres, and must not be switched under load, as

this will cause the contacts of the switches to arc.

4.1.3 SECONDARY WELDING CONNECTIONS

The secondary contactor, with parallel poles, is used to make

and break the circuit between the transformer secondary

and the rectier. This contactor is turned on and o when

the torch trigger (in the 24 volt circuit) is operated.

The secondary output welding terminals, POS.(+) and

NEG(-), are located in the right side wire feeding compart-

ment and are used to set the welding polarity (D.C.R.P. or

D.C.S.P.) in which the machine will operate (see Fig. 4.1).

As shipped from the factory, the 250 is set up to operate

in D.C.R.P. (TORCH tting is connected to Positive, and

WORK cable/clamp is connected to Negative output). To

weld using D.C.S.P., simply mount the WORK cable to the

Positive output and the TORCH tting cable to the Nega-

tive output terminal.

4.1.4 CONTACTOR CONTROL

Refer to the schematic diagrams. Note that the coil of the

24 volt contactor is activated with the torch trigger and is

energized when the trigger is pulled. The gas solenoid is

in parallel with the contactor coil and is energized at the

same time.

When the trigger switch is released, the contactor drops

out and disconnects the load.

Because of the charged capacitor bank in the second-

ary circuit, the output voltage will take a few seconds

before falling to zero volts.

The gas valve shuts o when the contactor opens.

4.1.5 WIRE FEED SPEED CONTROL

Wire feed speed is controlled by the wire speed potentiom-

eter knob on the front panel. The solid state control allows

for innitely variable speeds up to 650 IPM.

This wire speed pot is used to set the speed at which the

welding wire is fed out from the torch and hence the weld-

ing amperage. The panel-face numbers on the dial (0-10)

are used for reference and do not directly indicate wire feed

speed; the higher the number, the faster the speed.

4.1.6 STD./SPOOL GUN SELECTOR

This two-position toggle switch is located inside the unit

on the mid-wall of the wire feeding compartment and is

labeled Standard and Spool Gun. It is used to select standard

metal inert gas welding (MIG) with the GUNMASTER 250, or

welding with the ST-23A (spool-on-gun) torch.

4.2 PROCESS SETUP

4.2.1 STANDARD MIG SEAM WELDING W/

GUNMASTER 250

Refer to Sections 4.3.1, 4.3.2, 4.3.3, 4.3.4, and Table 4.3.3.

4.2.2 ST-23A SPOOL-ON-GUN CONTROL

CONNECTION/OPERATION

The Migmaster 250 is equipped with a built-in control for

the Spool Gun which operates via the amphenol control

receptacle and a screw adaptor that provides Gas and Power.

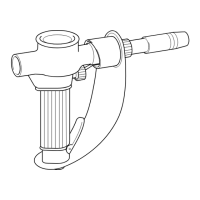

The ST-23A Torch (see Section 2.4.3) has a amphenol-plug

control cable connection, and a gas/power cable, see Figure

4.2.2.

To operate the unit with the ST-23A Torch connected, do

the following (refer to Fig. 4.2.2):

A. Place the STD./Spool Gun selector toggle switch (4.1.6)

in the 250 to its Spool Gun position.

B. Connect the ST-23A control cable amphenol to the re-

ceptacle labeled CONTROL on the 250’s front panel.

C. Remove the threaded plastic plug from the Gas/Power

adaptor (on the 250's front panel) using a clockwise

rotation. Connect the ST-23A gas/power cable to the

panel adaptor using a counter-clockwise rotation. As

shipped from the factory, the 250's secondary output

power terminals are set-up for D.C.R.P. welding polar-

ity (see Section 4.1.3).

SECTION 4 OPERATION

Loading...

Loading...