24

3.4 TORCH CONNECTIONS

The torch (GUNMASTER 250), which is supplied as standard

equipment with the Migmaster 250 System, is provided

with a euro-type adapter which directly connects to the

torch tting mounted on the front panel. Line up matching

holes, push on and tighten locking collar. As shipped from

the factory, the euro or common connector type torches

are set-up for D.C.R.P. welding polarity (see sections 3.3

or 4.1.3). To connect the spool-on-gun torch (ST-23A) see

Section 4.2.2.

3.5 WIRE FEEDER MECHANISM

3.5.1 DRIVE ROLLS

The drive roll has two grooves: the small groove feeds 0.035

in. diameter wire, the large groove feeds 0.045 in. wire. The

groove nearest the gear motor feeds the wire. If the required

groove is not in that position:

A. Release the pressure drive roll lever and lift the

assembly upward.

B. Remove the two (2) screws holding the drive roll to

the gear.

C. Reverse the drive roll on the drive roll shaft.

D. Replace the screws and tighten.

E. Secure the pressure drive roll assembly.

3.5.2 WELDING WIRE SPOOL

As with any work area, make sure safety glasses with side

shields are worn when handling or changing wire or clip-

ping wire o at the spool or at the end of the torch. Hold

onto the wire coming o the spool with one hand before

clipping. Serious eye injury can result due to the springi-

ness of the wire which can quickly unravel, or a cut wire

end which may shoot across the room.

Install a spool of welding wire on the hub as follows:

A. Unscrew spool nut from hub.

B. Place wire spool on hub to rotate clockwise as wire

is unwound; hub pin must engage hole in spool.

C. Replace nut.

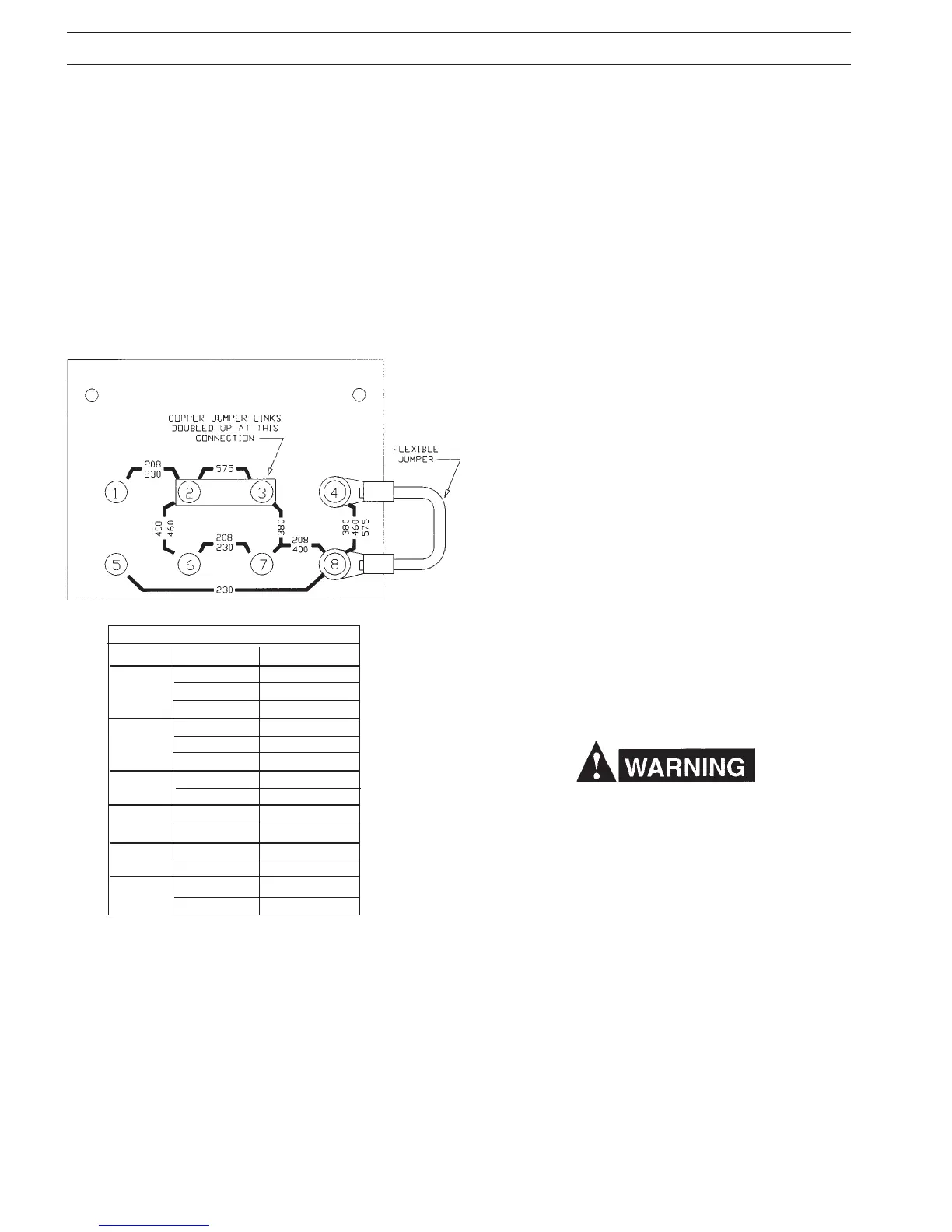

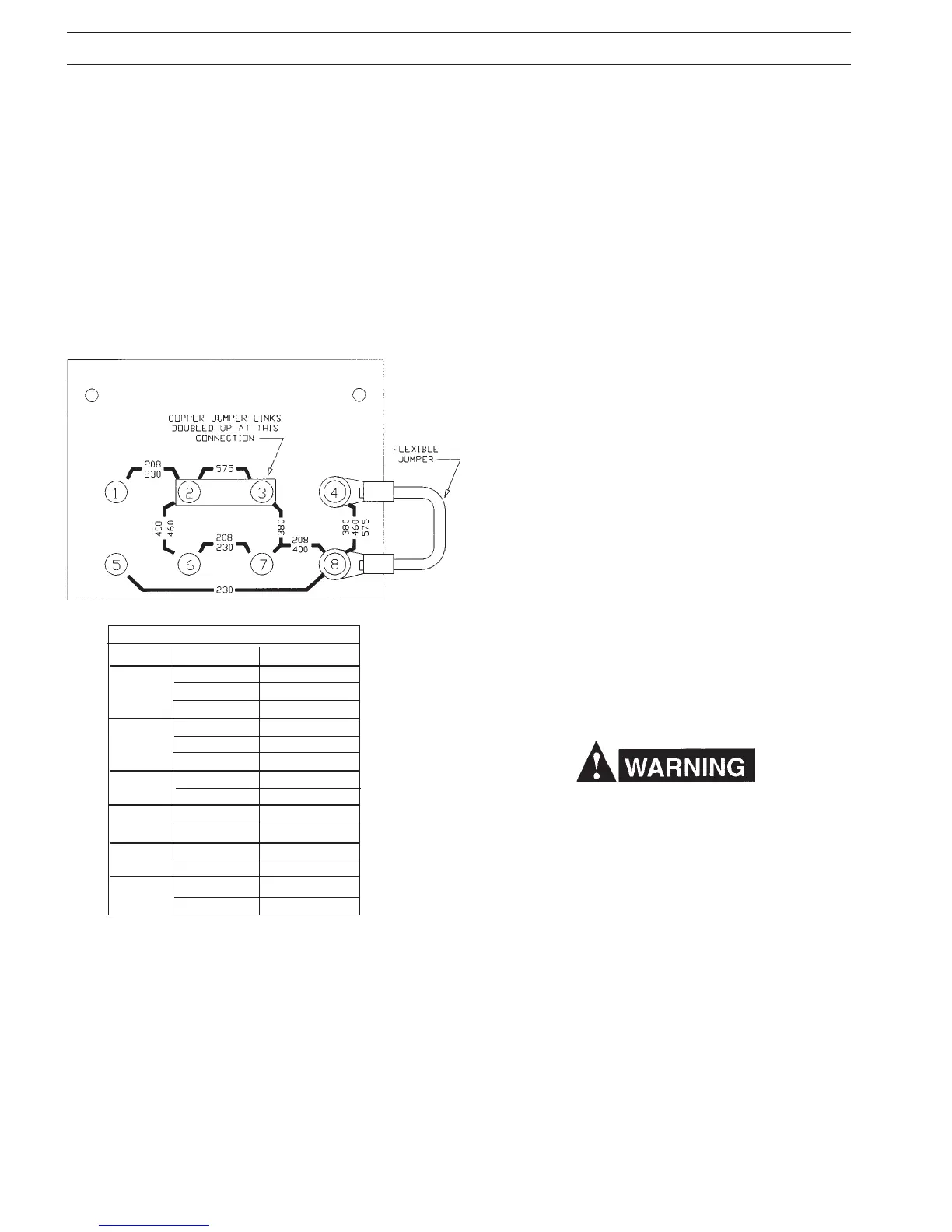

3.2.5 RECONNECTING FROM 575 VAC INPUT

Figure 3.3.1 shows you how to reconnect the "multi-voltage"

model from a 575-volt input to any of the remaining avail-

able voltage inputs 200 or 380 or 400 or 460-volts. These

connections are made by unscrewing the right side panel

below the wire feeding compartment, and locating the

primary voltage changeover terminal board handing in the

center of the lower compartment. This board contains copper

links which must be reconnected to match the silk-screened

voltage designations for the input you plan to use (it comes

factory-connected for a 575-volt input), see Figure 3.3.1.

3.3 SECONDARY OUTPUT CONNECTIONS

The Migmaster 250 Welding System is completely self-

contained so that the front panel torch ttings (Euro-type

MT and Spool gun) are internally connected to the welding

polarity (D.C. Reverse or D.C. Straight) via the secondary

output terminals located inside the wire feeding compart-

ment (see Fig. 4.1). The machine comes set up for D.C.R.P.

welding as described in Section 4.1.3.

Figure 3.3.1-Primary Reconnections at Voltage Changeover Terminal

Board for 208/230/380/400/460/575Volt Models

PRIMARY VOLTAGE CONNECTION CHART

VOLTAGE CONNECTION NO. OF STRIPS

1 - 2 1

208 6 - 7 1

7 - 8 FLEX

1 - 2 1

230 6 - 7 1

5 - 8 FLEX

380 3 - 7 2

4 - 8 FLEX

400 2 - 6 2

7 - 8 FLEX

460 2 - 6 2

4 - 8 FLEX

575 2 - 3 2

4 - 8 FLEX

SECTION 3 INSTALLATION

Loading...

Loading...