33

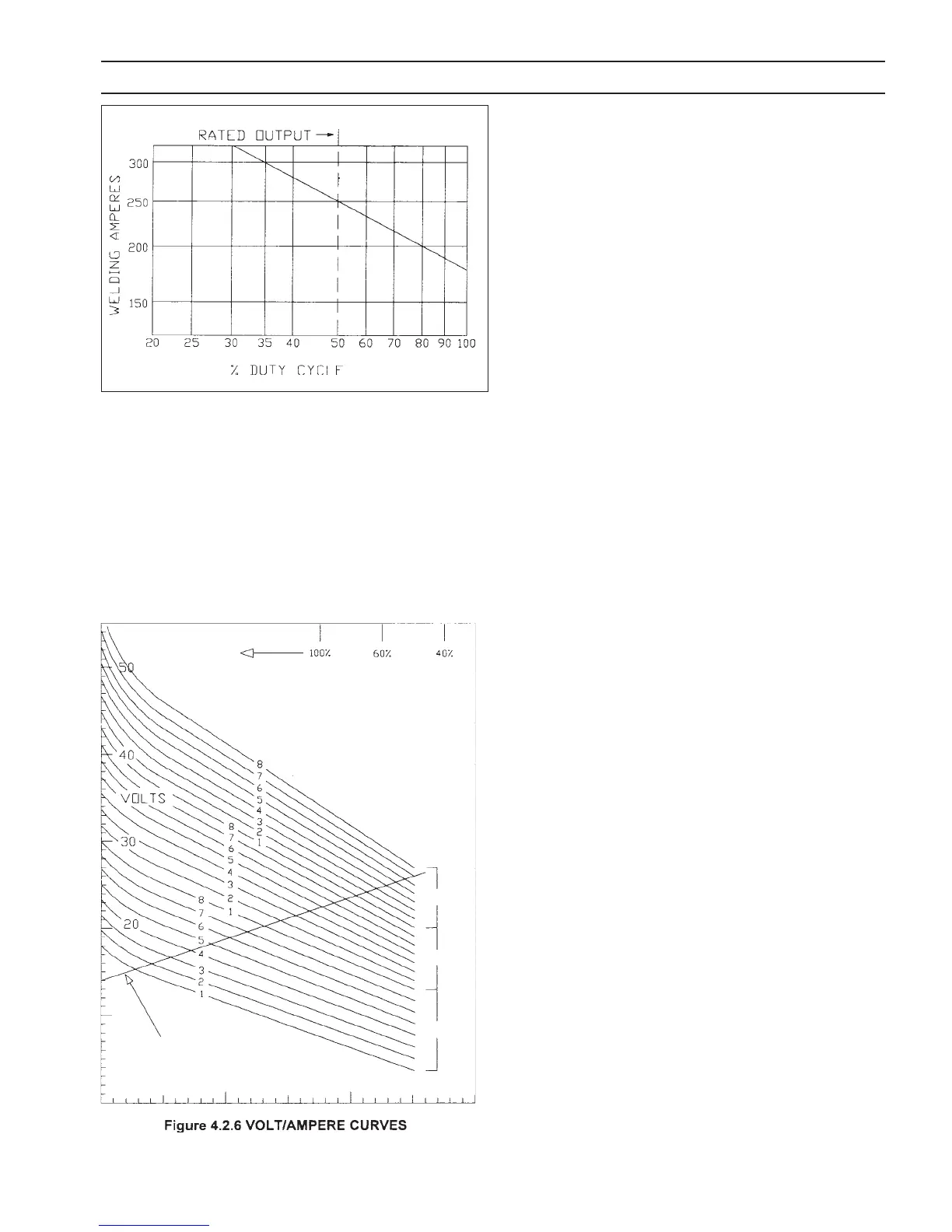

Fig. 4.2.5 Duty Cycle Curves

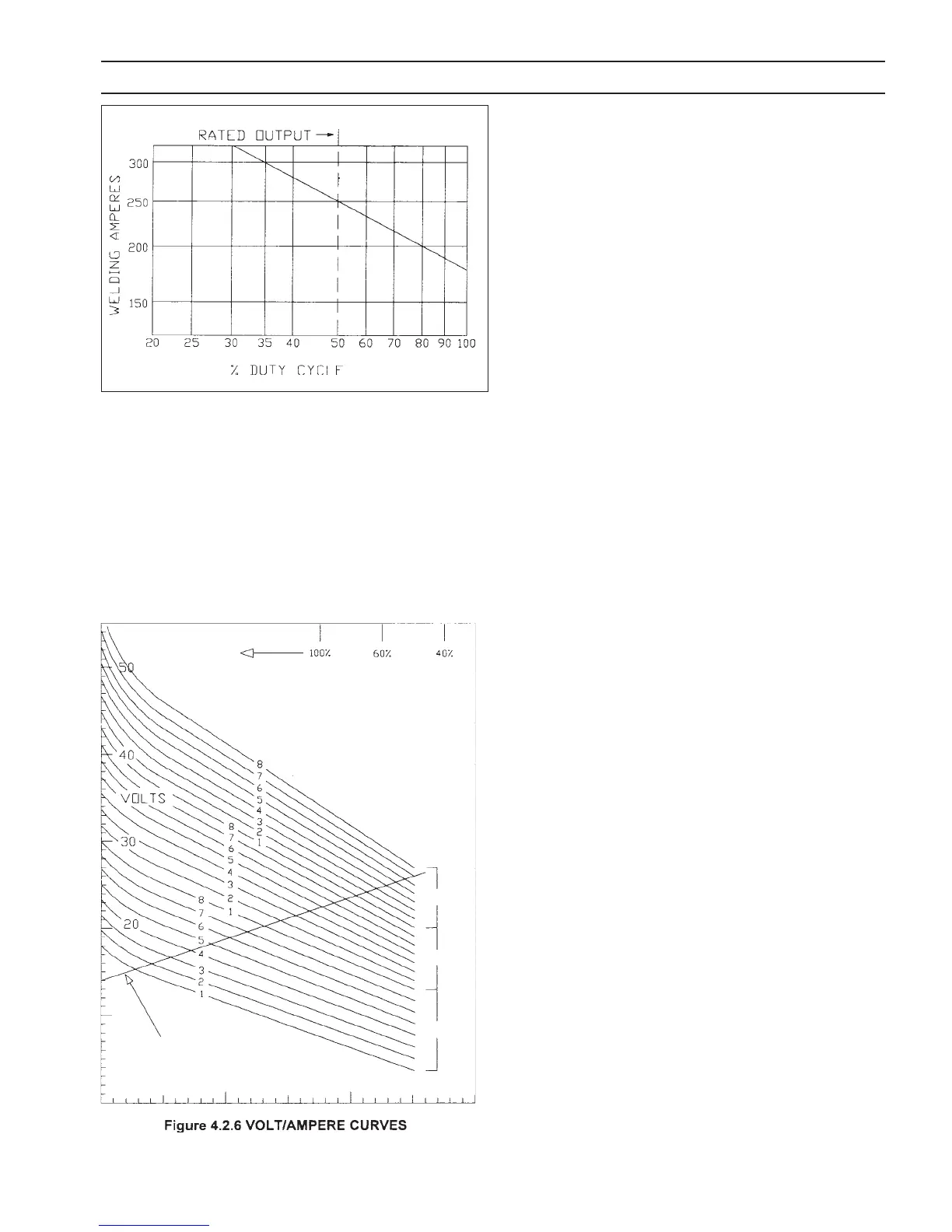

4.2.6 VOLT/AMPERE CURVES (Figure 4.2.6)

The Volt/Ampere curves show the output Voltage available

at any given output current for the various Voltage Selector

positions in each range low, medium, and high.

The actual operating point of load Voltage and Current is

determined by type of process, electrode, shield gas, wire

feed speed, and operating technique.

4.3 OPERATING PROCEDURES

4.3.1 OPERATING SAFETY PRECAUTIONS

Comply with all ventilation, re and other safety require-

ments for arc welding as established in the SAFETY Section

at the front of this manual.

Also remember the following:

A. Because of the radiant energy of the welding arc

and the possibility of drawing an arc before the

helmet is lowered over the face, the operator should

wear ash goggles with lter lenses under his helmet.

The helmet lter plated should be shade number

11 (nonferrous) or 12 (ferrous). All those viewing the

arc should use helmets with lter plates, as well as

ash goggles. Nearby personnel should wear ash

goggles.

B. The radiant energy of the arc can decompose chlori-

nated solvent vapors, such as trichloroethylene and

perchlorethylene, to form phosgene, even when

these vapors are present in low concentrations. DO

NOT weld where chlorinated solvents are present in

atmospheres in or around the arc.

C. DO NOT touch the electrode, nozzle or metal parts in

contact with them when power in ON: all are electri-

cally energized (HOT) and can cause a possibly fatal

shock. DO NOT allow electrode to touch grounded

metal: it will create an arc ash that can injure eyes.

It may also start a re or cause other damage.

D. When working in a conned space, be sure it is

safe to enter. The conned space should be tested

for adequate oxygen (at least 19%) with an approved

oxygen measuring instrument. The conned space

should not contain toxic concentrations of fumes or

gases. If this cannot be determined, the

operator should wear an approved air supplied

breathing apparatus.

Avoid gas leaks in a conned space, as the leaked gas can

dangerously reduce oxygen concentration in the breath-

ing air.

DO NOT bring gas cylinders into conned spaces.

When leaving a conned space, shut OFF gas supply at the

source to prevent gas from leaking into the space, if the

switch is accidently kept depressed. Check the breathing

atmosphere in the conned space to be sure it is safe to

reenter.

DUTY CYCLE

HIGH

MED.

LOW

LOAD LINE

VOLTS = 14+ (.05 x AMPS)

50

100

150

200

250

AMPERES

SECTION 4 OPERATION

Loading...

Loading...