25

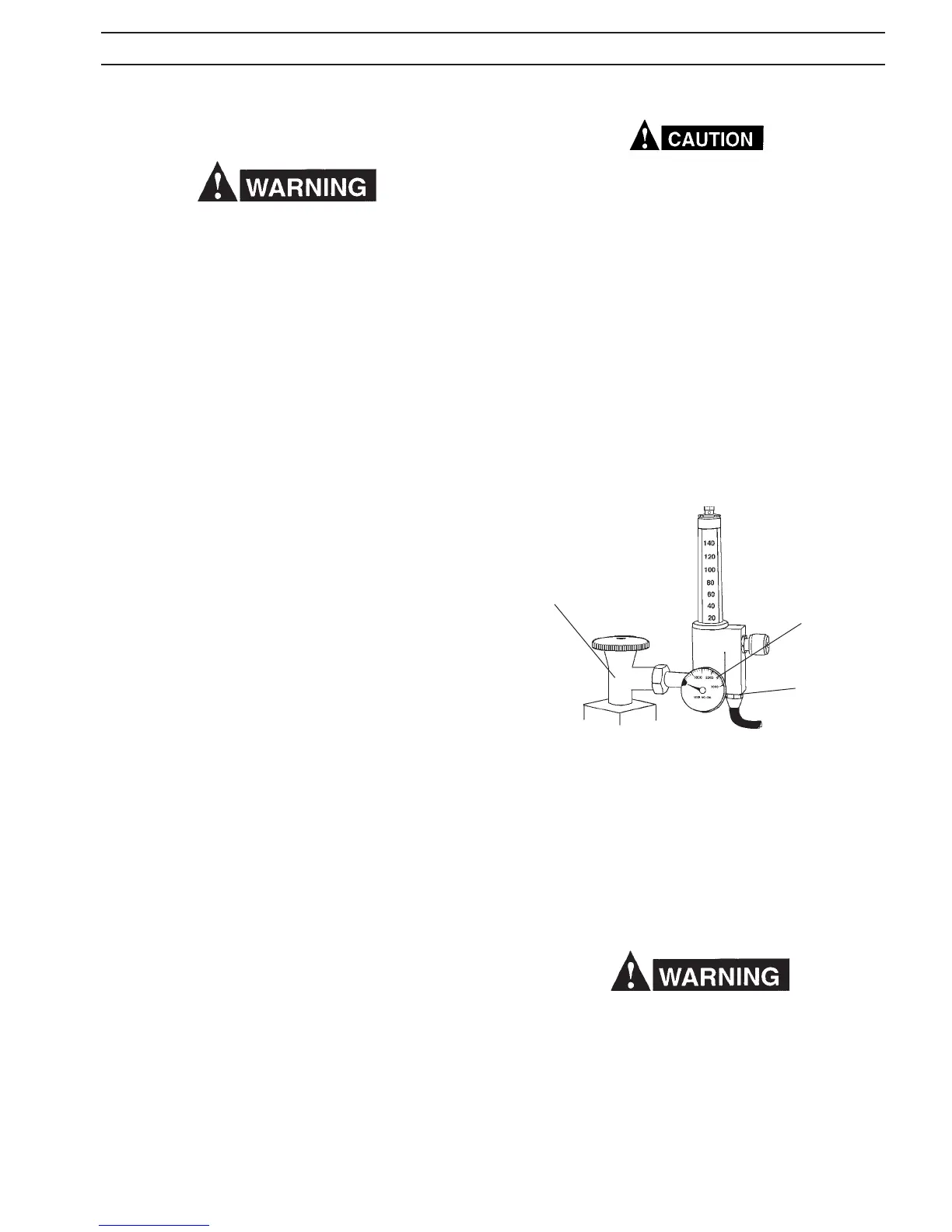

OUTLET

CONNECTION

CYLINDER

PRESSURE

GAUGE

Do Not adapt R-33-FM-580 for use with CO

2

. Relief device

may rupture if CO

2

is used with the R-33-FM-580. For CO

2

service, order R-33-FM-320, P/N 21558.

a. With the cylinder cap in place CAREFULLY slide

the cylinder of gas onto the Migmaster 250 cylinder

rack.

b. Secure the cylinder to the unit, using the chain

provided.

c. Unscrew the cylinder cap.

d. Open the cylinder valve slightly, just for an instant,

to blow away any dirt or dust which may have ac-

cumulated in the cylinder valve outlet. Be sure to

keep your face away from the valve outlet

to protect your eyes.

e. Attach the regulator to the cylinder valve, tighten

the union nut securely with a 1-1/8in. open end or an

adjustable wrench.

Fig. 3.6 R-33-FM-580 Regulator (Illustrated)

CYLINDER

VALVE

3.5.3 THREADING WELDING WIRE

A. Turn o power switch.

When the power switch is on, and gun trigger is depressed,

the electrode wire becomes electrically hot, and the wire

feed rolls are activated.

B. Release pressure drive roll assembly and lift up

ward. Check that proper wire diameter groove is in

the inner position.

CAUTION: Before threading welding wire through casing,

make sure chisel point and burrs have been

removed from wire end to prevent wire from

jamming in gun casing or liner.

C. Feed the wire from the spool through the inlet

guide, across the drive roll groove and into gun

outlet guide.

Make sure that the proper “outlet guide tube” is inserted

into the front-panel gun tting for the size and type of

wire being used, see Table 2.4.5.2 for wire feed accessories

(Section 2.4.5).

To insure proper wire feeding, it is important that the wire

be kept clean and that the drive rolls be periodically cleaned

of any chips or scale that might be carried into the gun liner

and cause sticking.

D. Lower pressure roll assembly and secure. Check

that the gears mesh. Feed wire through to gun tip

with gun trigger (power ON).

3.5.4 BRAKE DRAG ADJUSTMENT

Brake disc friction should provide enough drag to keep the

wire spool or core from spinning freely after wire feed stops.

If adjustment is required, turn adjusting screw clockwise to

increase drag, counterclockwise to decrease it. Drag should

be just low enough to limit wire

overrun.

3.6 CONNECTION OF SHIELDING GAS SUPPLY

The R-33-FM-580 Regulator-Flowmeter is designed for use

with an argon or argon-mix cylinder of shielding gas. It is

adjustable for delivering up to 50 cfh through the torch. To

set up the system do the following:

SECTION 3 INSTALLATION

f. Attach the gas hose from the rear of the Migmaster 250

to the regulator outlet connection (see Fig. 3.6).

g. Slowly open the cylinder valve a fraction of a turn.

When the regulator pressure gauge pointer stops

moving, open the cylinder valve fully.

Never stand directly in front of or behind the regulator when

opening the cylinder valve. Always stand to one side.

Loading...

Loading...