Do you have a question about the ESAB Mig 4002cw and is the answer not in the manual?

Details who should perform maintenance and repair work, emphasizing qualified personnel and safety precautions.

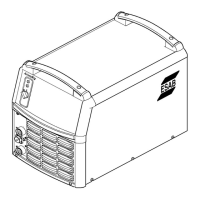

Provides detailed technical specifications for OrigoTM Mig 4002cw, 5002cw, and 6502cw models, including voltage and current ratings.

Lists and describes the function of various electrical components shown in the wiring diagram for troubleshooting.

Explains the CBO board's role in monitoring, controlling power source functions, and obtaining welding data.

Outlines ACH10 board functions: transistor control, capacitor monitoring, and fan/pump management.

Describes the current sensor, its calibration process, and procedures for replacement.

Explains arc voltage sensing for MIG/MAG welding and the calibration process.

Lists and explains fault codes specific to the power source, including troubleshooting actions.

Provides essential guidelines for handling electrostatic sensitive devices to prevent damage.

Details how to check the PWM signal on CB0 and ACH10 boards using an oscilloscope.

Outlines general safety regulations, operator responsibilities, and workplace requirements for welding equipment.

Covers professional installation, lifting, and correct placement of the welding power source.

Recommends regular inspection, cleaning, and coolant level management for reliable operation.

Offers recommended checks and inspections for common faults like no arc or poor welding performance.

| Brand | ESAB |

|---|---|

| Model | Mig 4002cw |

| Category | Welding System |

| Language | English |