7 FAULT-TRACING

0458 870 201

- 14 -

© ESAB AB 2014

7 FAULT-TRACING

Please also read the operating instructions for the welding components, e.g. power source

and wire feed unit.

If the measures described below are not successful, consult your dealer or the manufacturer.

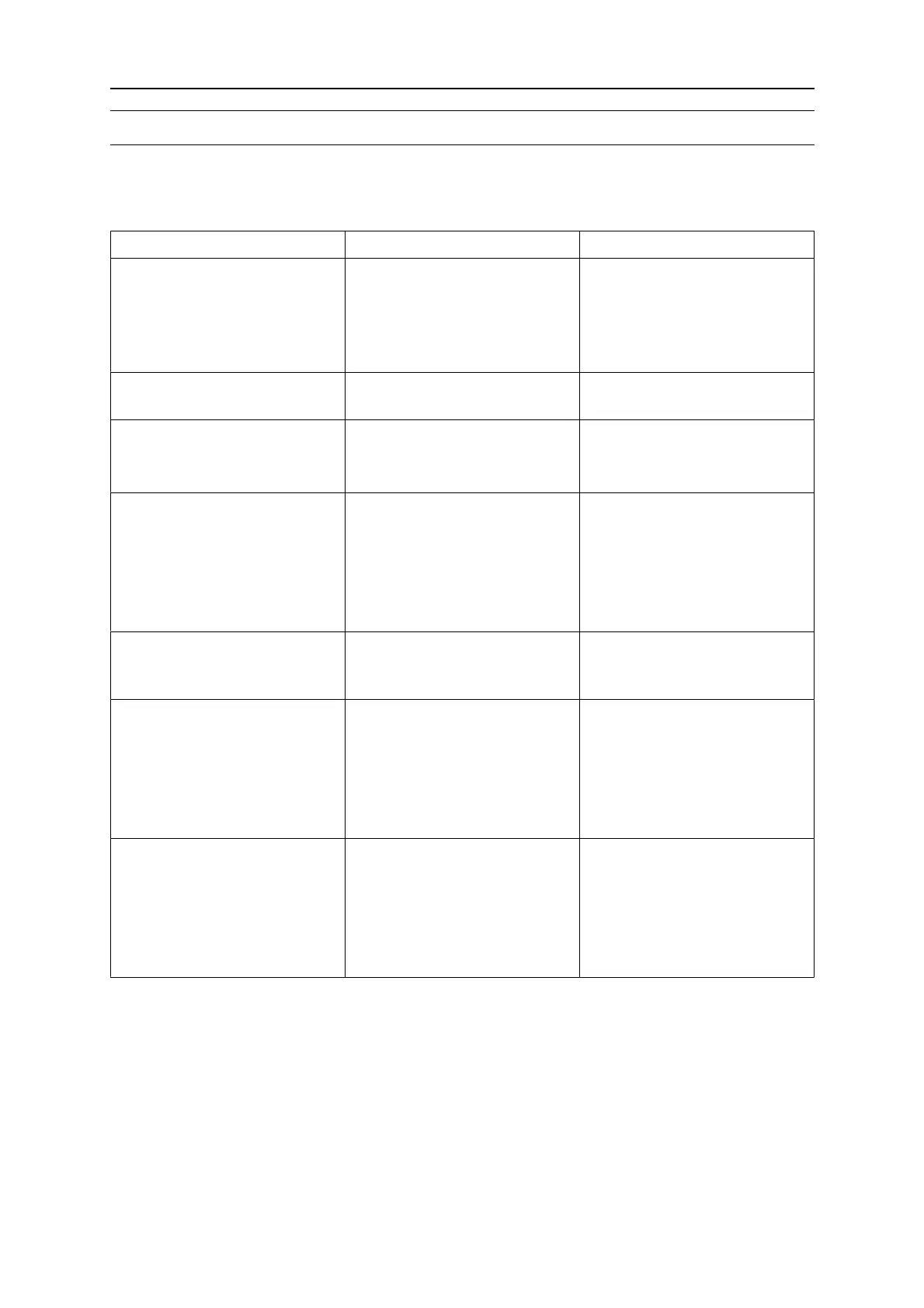

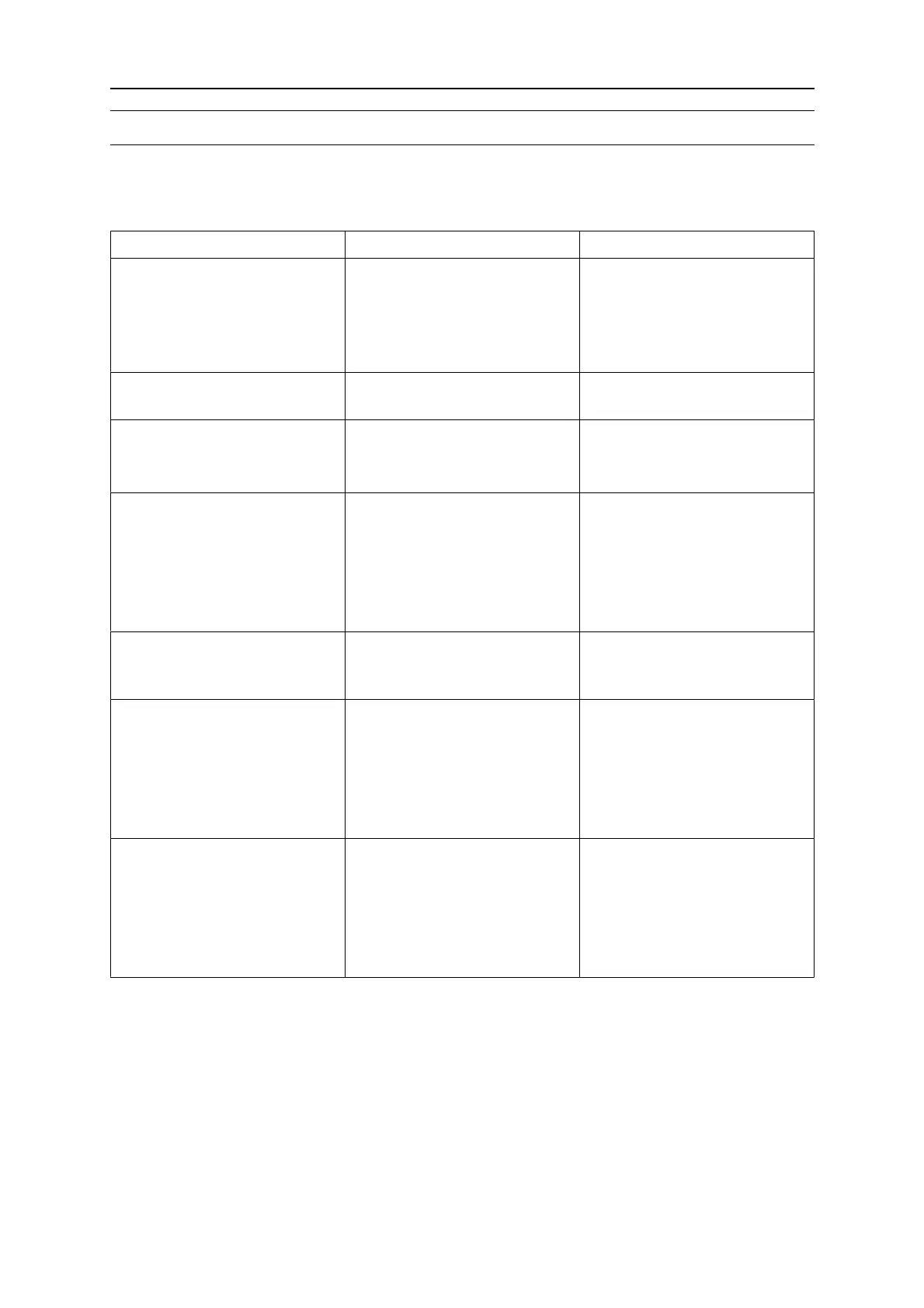

Problem Cause Solution

Welding torch becomes too

hot

• Contact tip is not tight

enough.

• Electrical connections to

the welding torch and to

the workpiece.

• Check and tighten.

• Check and tighten.

No trigger function • Control cable

interrupted/faulty.

• Check/repair.

Wire burnt back on the

contact tip at stop

• Wrong burn back time

set.

• Worn contact tip.

• Decrease the burn back

time.

• Replace.

Irregular wire feed • Liner blocked.

• Contact tip and wire

diameter do not match.

• Wrong tension set on the

wire feed unit.

• Blow through in both

directions.

• Replace contact tip.

• Correct according to

manufacturer's

instructions.

Short arc between the gas

nozzle and workpiece.

• Spatter bridge between

the contact tip and gas

nozzle.

• Clean and spray the

inside of the gas nozzle.

Variable arc • Contact tip is worn or

does not match the wire

diameter.

• Incorrect welding

parameters set.

• Liner worn.

• Check/replace the

contact tip.

• Correct the welding

parameters.

• Replace the wire liner.

Porous welds • Large amount of spatter

in the gas nozzle.

• Insufficient or total lack of

shielding gas.

• Draught is disturbing the

shielding gas.

• Clean the gas nozzle.

• Check contents of the

gas bottle/hoses and the

pressure setting.

• Shield welding area with

protective screens.

Loading...

Loading...