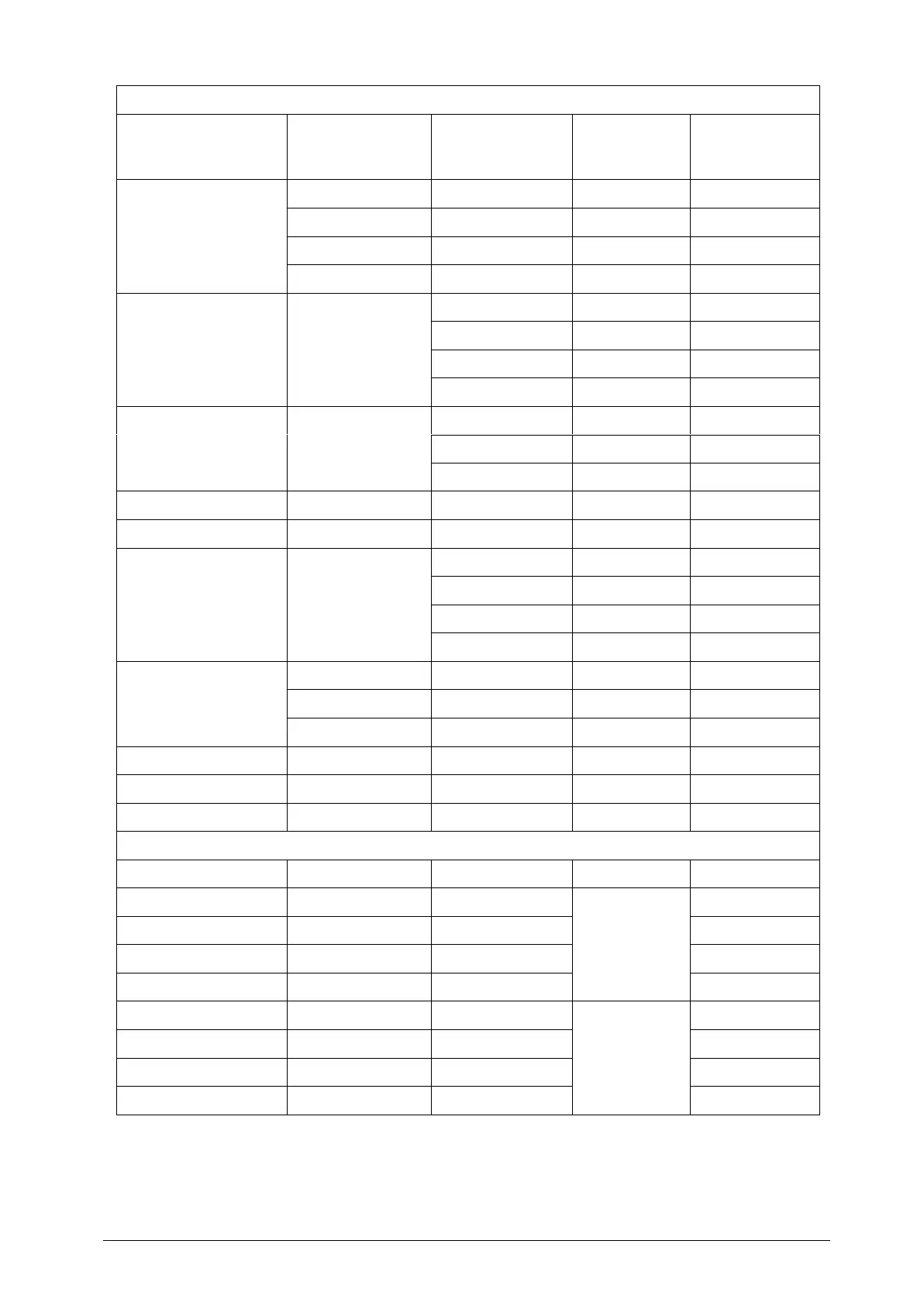

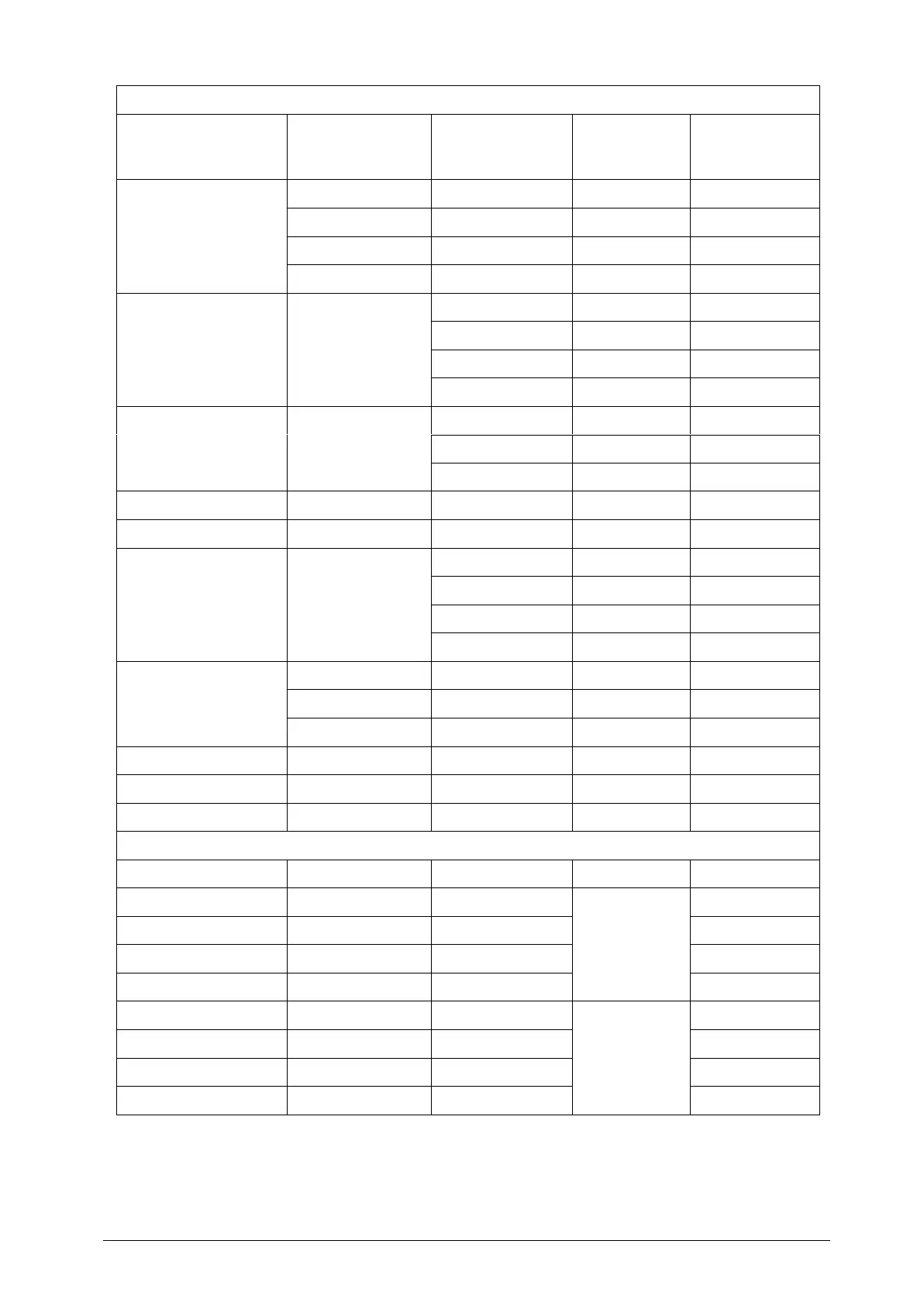

(1) As a rule of thumb, start with a shade that is too dark, then go to a lighter shade which gives a sufficient view of the weld zone without

going below the minimum. In oxyfuel gas welding or cutting where the torch produces a high yellow light, it is desirable to use a filter

lens that absorbs the yellow or sodium line the visible light of the (spectrum) operation.

(2) These values apply where the actual arc is seen. Experience has shown that lighter filters may be used when the arc is hidden by the

workpiece.

Data from ANSI Z49.1-2005

Loading...

Loading...