C

21

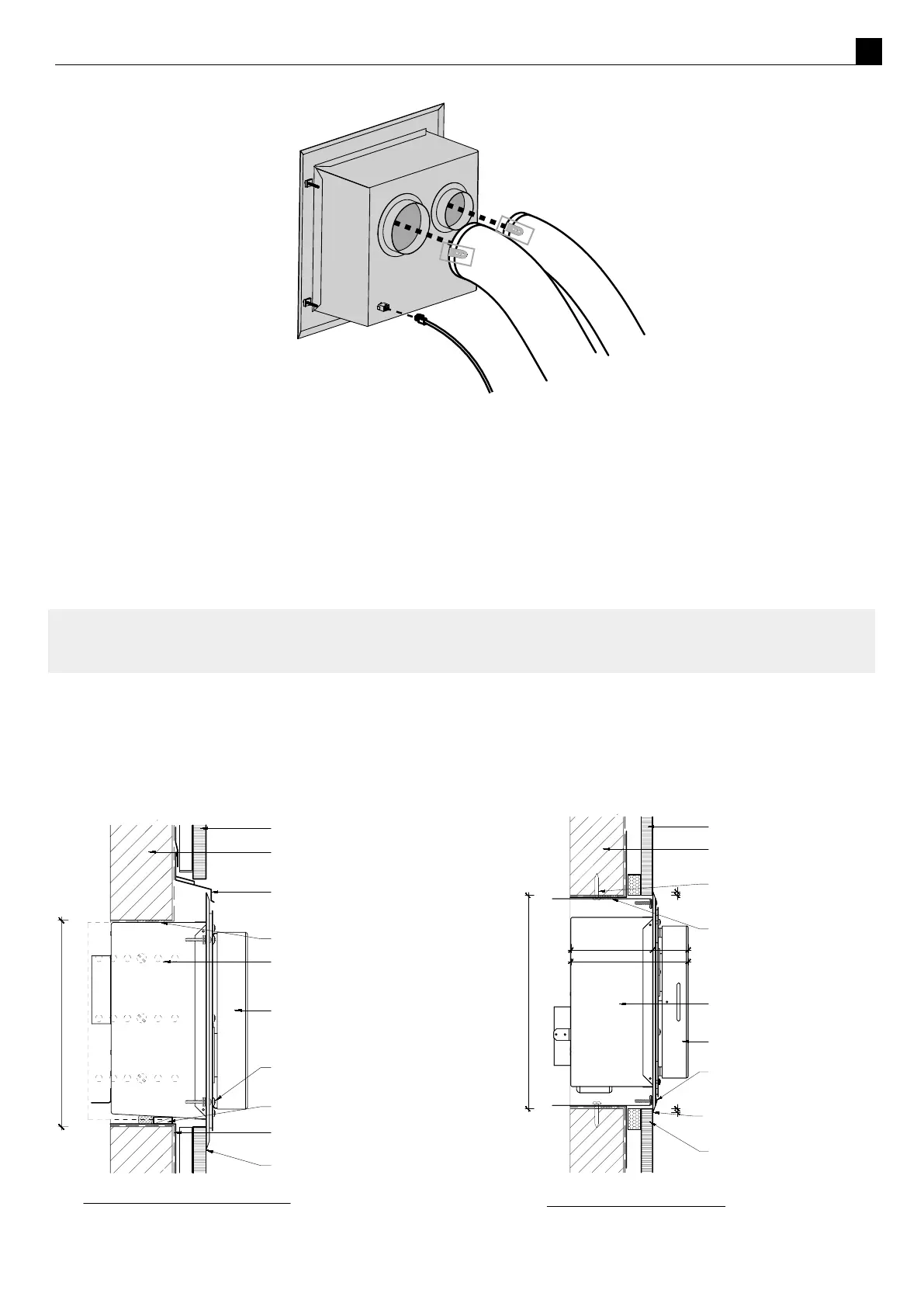

Fit the Horizontal Power Flue Wall Terminal into the hole and x it in place, making sure the installaon is sealed

appropriately to prevent the ingress of water from outside the wall cladding.

Note: It is the responsibility of the installer to ensure the horizontal Power Flue wall terminal is installed to

all relevant building codes to ensure weather ghtness. This may necessitate the use of appropriate ashing

material where appropriate.

IMPORTANT: ENSURE THAT FLASHINGS DO NOT RESTRICT THE AIR INTAKE SLOT AROUND THE PERIPHERY

How to Flash the Horizontal Power Flue

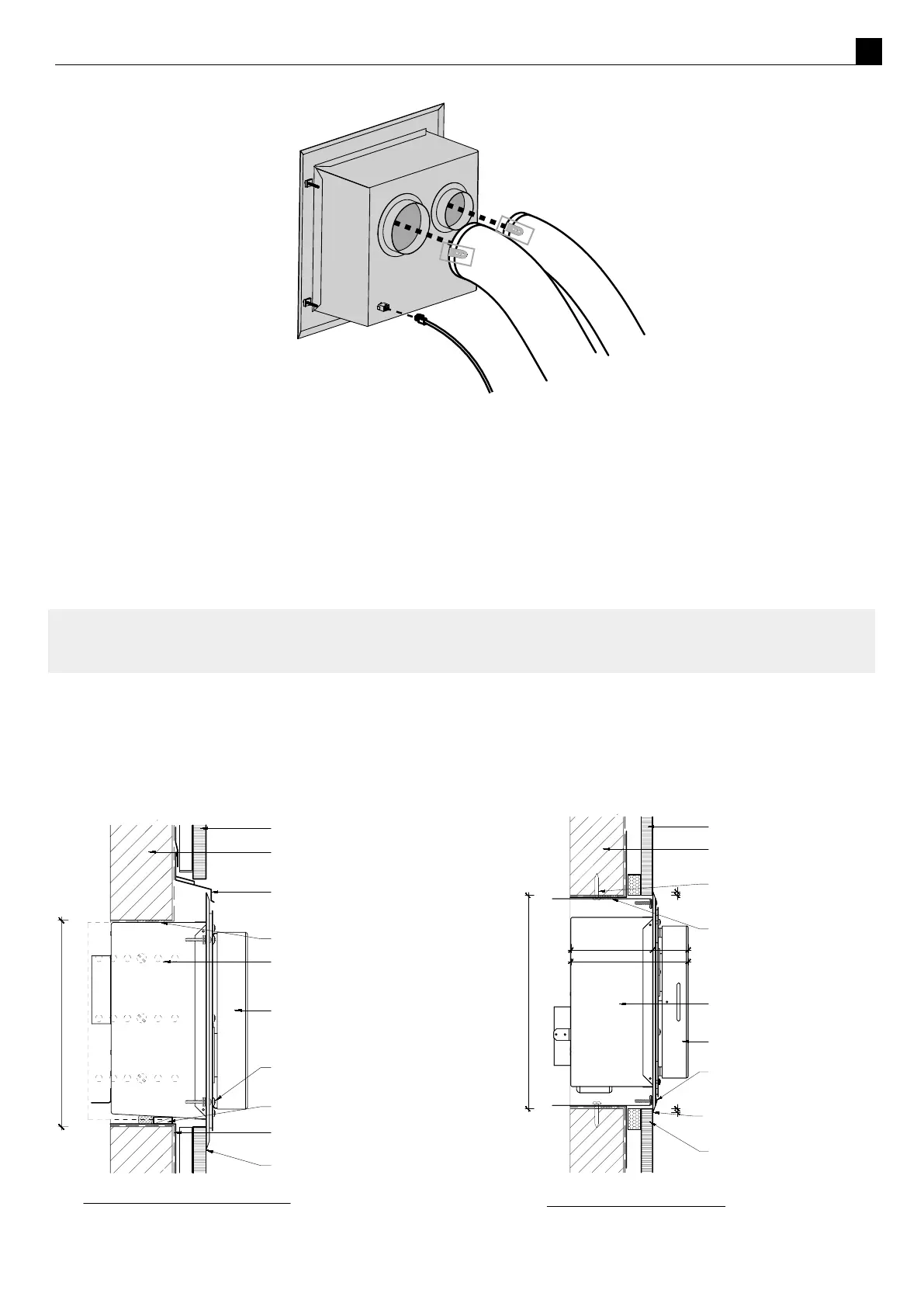

The following diagrams are excerpts from the Escea architect drawings and are available in full on our website.

These diagrams are recommendaons, and your installaon must comply with any local or naonal building

codes.

Head and Sill scale 1:5

framing member with

wall wrap and flashing

tape over

cladding on cavity

batten

typical head flashing with

stop ends to comply with

relevant building code

horizontal powerflue

unit

terminal fixing brackets

(shown dashed) fixed

to framing

flashing tape over wall

wrap to opening

seal air gap to opening

terminal screw fixed to flange

with flange fixed to studs at

fixing brackets

packer to lift terminal off

sill

sill cover to cladding to compl

with relevant building code

300 min

360 min

10

cladding on cavity

batten

10

horizontal powerflue

unit

terminal screw fixed to flange

with flange fixed to studs at

fixing brackets

terminal fixing

brackets screw fixed

into framing

framing member with

wall wrap and flashing

tape over

continuous sealant strip

to jambs

scriber or plug may be

required - dependent on

cladding type

seal air gap to opening

cowl

198

138 60

scale: date:

ecn:

drawn:

drawing no:

revision:file:

Horizontal Powerflue Detail

as shown ECN-2155 EDA-0006 MGD-Series FLUE Master File.dwg

V. 02 08.12.2017

Jamb scale 1:5

framing member with

wall wrap and flashing

tape over

cladding on cavity

batten

typical head flashing with

stop ends to comply with

relevant building code

horizontal powerflue

unit

terminal fixing brackets

(shown dashed) fixed

to framing

flashing tape over wall

wrap to opening

seal air gap to opening

terminal screw fixed to flange

with flange fixed to studs at

fixing brackets

packer to lift terminal off

sill

sill cover to cladding to compl

with relevant building code

300 min

360 min

10

cladding on cavity

batten

10

horizontal powerflue

unit

terminal screw fixed to flange

with flange fixed to studs at

fixing brackets

terminal fixing

brackets screw fixed

into framing

framing member with

wall wrap and flashing

tape over

continuous sealant strip

to jambs

scriber or plug may be

required - dependent on

cladding type

seal air gap to opening

cowl

198

138 60

scale: date:

ecn:

drawn:

drawing no:

revision:file:

Horizontal Powerflue Detail

as shown ECN-2155 EDA-0006 MGD-Series FLUE Master File.dwg

V. 02 08.12.2017

Loading...

Loading...