Do you have a question about the ESPEC Platinous Series and is the answer not in the manual?

Explains the meaning of safety symbols used in the manual for safe operation.

Guide to understanding the chamber model number configuration based on its features.

Lists the accessories and spare parts included with the chamber.

Lists explosives, combustibles, and corrosive substances to avoid placing inside the chamber.

Details on setting safety devices to prevent specimen damage during testing.

Procedures for safely disposing of the chamber, including door removal.

General safety precautions, including grounding and handling hot/cold conditions.

Information on identifying and understanding warning labels posted on the chamber.

Lists refrigerants used and their global warming potential.

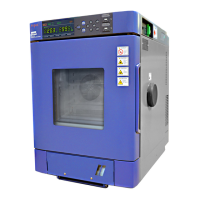

Introduction to the Platinous Series chambers and their testing capabilities.

Explanation of the BTHC system and SCP-220 instrumentation.

Identifies and describes parts on the front and right sides of the chamber.

Identifies and describes parts on the left, rear, and top sides of the chamber.

Details components within the primary test area of the chamber.

Details components located in the test area ceiling.

Details the instrumentation panel and its various components.

Explains the functions of the operating panel and touchscreen elements.

Describes the components within the electrical compartment.

Details the components within the water circuit compartment.

Guidelines for selecting an appropriate installation site and required space.

Step-by-step instructions for leveling and moving the chamber.

Requirements and connections for the primary power supply.

Instructions for removing shipping brackets from the compressor.

Details on connecting water-cooled chambers to the water supply.

Procedures for setting up and managing chamber drainage.

Procedures for checking and maintaining water levels in the humidifying tray and wick pan.

Instructions for connecting the water supply hose to the humidifying tray circuit.

Steps to supply water to the humidifying tray by operating the chamber.

Procedure to confirm adequate water level in the humidifying tray.

How to check and adjust the water level in the humidifying tray water level regulator.

Procedure for checking and regulating the water level in the wick pan.

Steps for preparing the chamber and specimens for testing.

Guidance on properly arranging specimens for optimal air circulation.

Instructions for connecting power to specimens via control terminals.

Procedure for installing and checking the wet-bulb wick for humidity tests.

How to set overheat protector and alarm limits for specimen safety.

Setting the overheat protector before beginning tests.

Setting temperature/humidity alarms to protect specimens and chamber.

Guide to inputting desired temperature and humidity for constant mode operation.

Procedures for starting, running, and ending tests.

Steps for initiating a test run in the chamber.

Methods to prevent dew formation on specimens during testing.

Procedures for properly ending a test and shutting down the chamber.

Explanation of features like auto/manual refrigeration, time signals, and external alarms.

How to set and use automatic or manual refrigeration capacity control.

Utilizing time signals to control external equipment or specimens.

Purpose and usage of the external alarm terminal for notifications.

Overview of periodic checks and maintenance tasks for the chamber.

Procedures for performing routine checks like power switch and overheat protector tests.

How to perform a trip test on the main power switch.

Procedure for testing the overheat protector before each test.

Detailed procedures for cleaning various chamber components.

Instructions for cleaning dust and debris from the condenser.

How to remove and wash the water filter strainer.

Procedures for cleaning the humidifying tray and heater.

Steps for maintaining humidifier atomizing nozzles, including cleaning.

How to clean the test area to ensure accurate test results.

Procedures for cleaning dust from electrical and water circuit compartments.

Steps for preparing the chamber for extended periods of non-use.

Information on consumable parts and their recommended replacement intervals.

Guide to identifying and resolving problems indicated by alarm codes.

Explains how to handle alarms based on the chamber's operating state.

A table listing alarm codes, troubles, causes, and remedial actions.

Addresses common operator errors and problems not covered by alarms.

Instructions for user-level maintenance tasks like replacing fuses and lamps.

Procedure for replacing blown fuses in the chamber.

Steps for replacing the chamber lamp bulb.

Procedure for replacing the chamber lamp starter.

Instructions for defrosting the chamber when frost forms.

Detailed specifications for various ESPEC chamber series.

Technical specifications for the ESL Series chambers.

Technical specifications for the ESU Series chambers.

Technical specifications for the ESX Series chambers.

Technical specifications for the ESZ Series chambers.

Definitions of technical terms used throughout the manual.

Steps for requesting warranty service and parts from ESPEC.

| Temperature Control Accuracy | ±0.3°C |

|---|---|

| Humidity Range | 10 to 95% RH (depending on the model) |

| Heating Rate | 3 to 5°C/min (depending on the model and temperature range) |

| Cooling Rate | 1 to 3°C/min (depending on the model and temperature range) |

| Controller | Programmable touchscreen controller |