26

Gas Connection

• Only a suitably qualied and Gas Safe Registered Engineer may convert the appliance to

a dierent gas type.

• This cooker uses and is ready to use NATURAL GAS only and cannot be used with any other gas

without modication. This appliance is manufactured for conversion to LPG after tting new injectors

(supplied) and making adjustments. Refer to “replacement of burner injectors” section for details.

• When using Butane (G30) gas a supply pressure of 28 -30 mbar is required.

• When using Propane (G31) gas a supply pressure of 37 mbar is required.

• Flexible hoses must be manufactured in accordance with relevent standards and regulations in

force, and be suitable for gas type being used.

• The hose should not be crushed or trapped or be in contact with sharp or abrasive edges.

It should also not be subjected to corrosion by acidic cleansing agents.

Do not use a naked ame to test for leaks.

* All images are for indication only; please refer to your individual unit for actual item.

The installation of the cooker to Natural Gas or LP Gas (using the LPG conversion kit supplied) must be carried out

by a Gas Safe registered engineer. Installers must take account of the provisions of the relevant British Standards

Code of Practice, the Gas Safety Regulations and the Building Regulations.

Installation for Using Natural Gas

Installation to Natural Gas must conform to the Industry Standards, etc. The supply pressure for Natural Gas is 20 mbar.

Installation for Using Liquid Petroleum Gas (LPG)

This appliance must only be connected to LPG after the supplied LPG conversion kit has been tted.

The installation must conform to the relevant British Standards.

During gas connection and re-connection, a sealing material that is either

• PTFE tape approved to BS EN 751-3;

• Or jointing compound suitable for Natural Gas complying to BS 6956-5 or BS EN 751-1

should be used between connection surfaces.

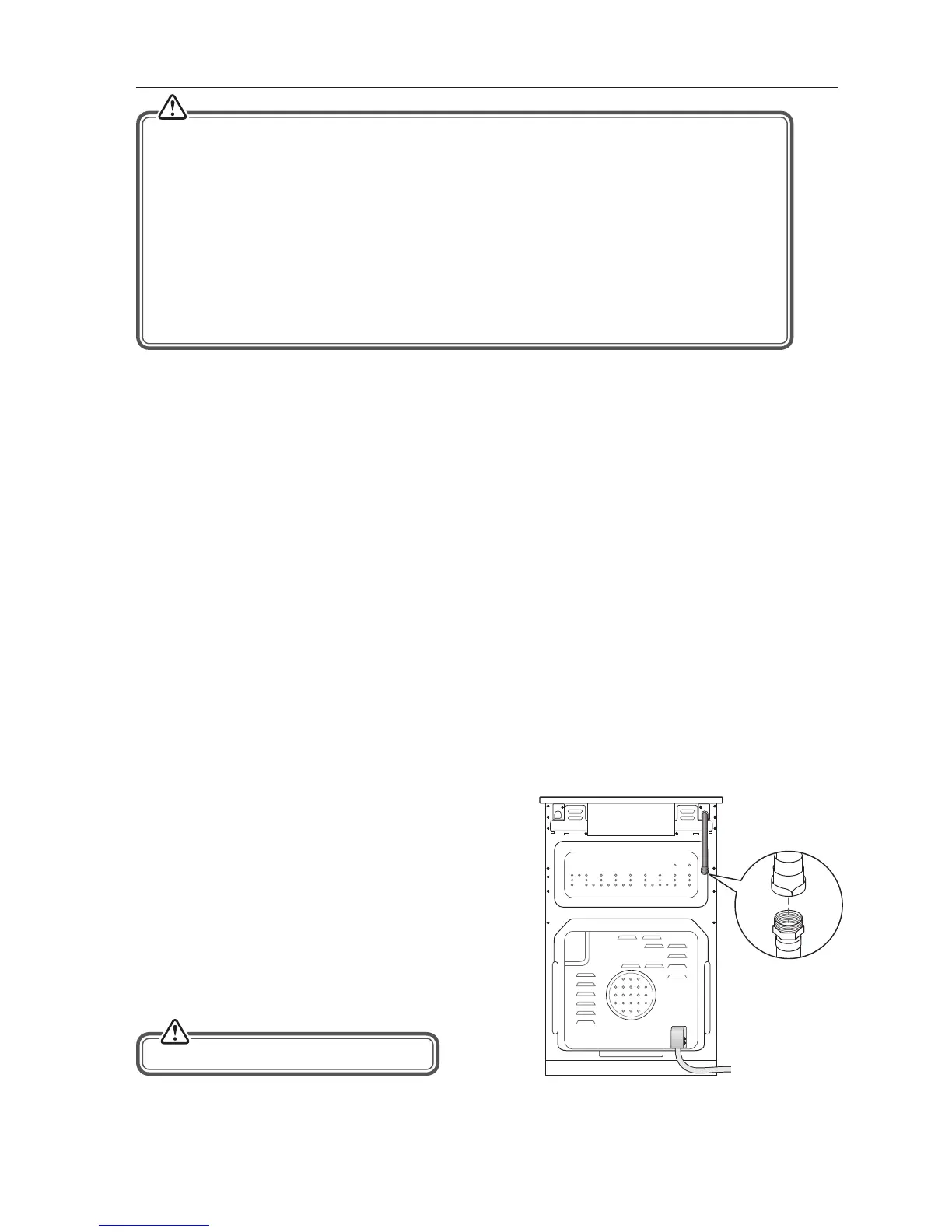

To Connect the Gas Supply

1. Connect the gas supply to the gas inlet at the rear

of the cooker. The gas hose must hang in a “U” shape

behind the cooker.

2. Undertake a full gas tightness test.

3. To avoid damage to the appliance gas rail inlet pipe

tighten the ttings using two suitable spanners.

4. Using a suitable leak detection uid solution check each

gas connection one at a time by brushing the solution

over the connection. The presence of bubbles will

indicate a leak. If there is a leak, tighten the tting and

then recheck for leaks.

Loading...

Loading...