7

ENGLISH

USEFUL SUGGESTIONS

Before starting a RETARDER-PROOFING cycle it is advisable to pre-cool the empty cell at -5 ° C,

thus allowing more effective action of the Retarder-proofing action during the introduction of the

product (see par.10.6 p. 29)

For cycles longer than 48 H increase yeast of 0.5% speeding as possible the loading phase of the

product.

Do not bake the product once it has been taken out from the retarder proofer, leave at least 10

minutes at room temperature in order to avoid an excess of moisture in the surface that could cause

defects in the crust formation during cooking.

The possible bubbles formation on the bread is not synonymous of failure in the system, the cause

is almost always due to a problem of bread: dough too soft, too cold, low-quality flour, too much

moisture in the leavening phase, the oven is too hot, excess of cooking steam, etc

Avoid too high temperatures along with too short times during LEAVENING and PROVING, thermal

shock should cause problems to gluten and yeast damaging the quality of the finished product.

In the case of products that require periods of storage longer than 72H is advisable to use special

temperature blast chiller (see our catalogues) designed to bring the inside part of bread in the shortest

time to a temperature of -20 ° C thus allowing to keep the original organoleptic quality comparing it

to the fresh product.

Even the storage phase must take place in a special cold room who keeps constantly t -20 ° C.

PRELIMINARY NOTES

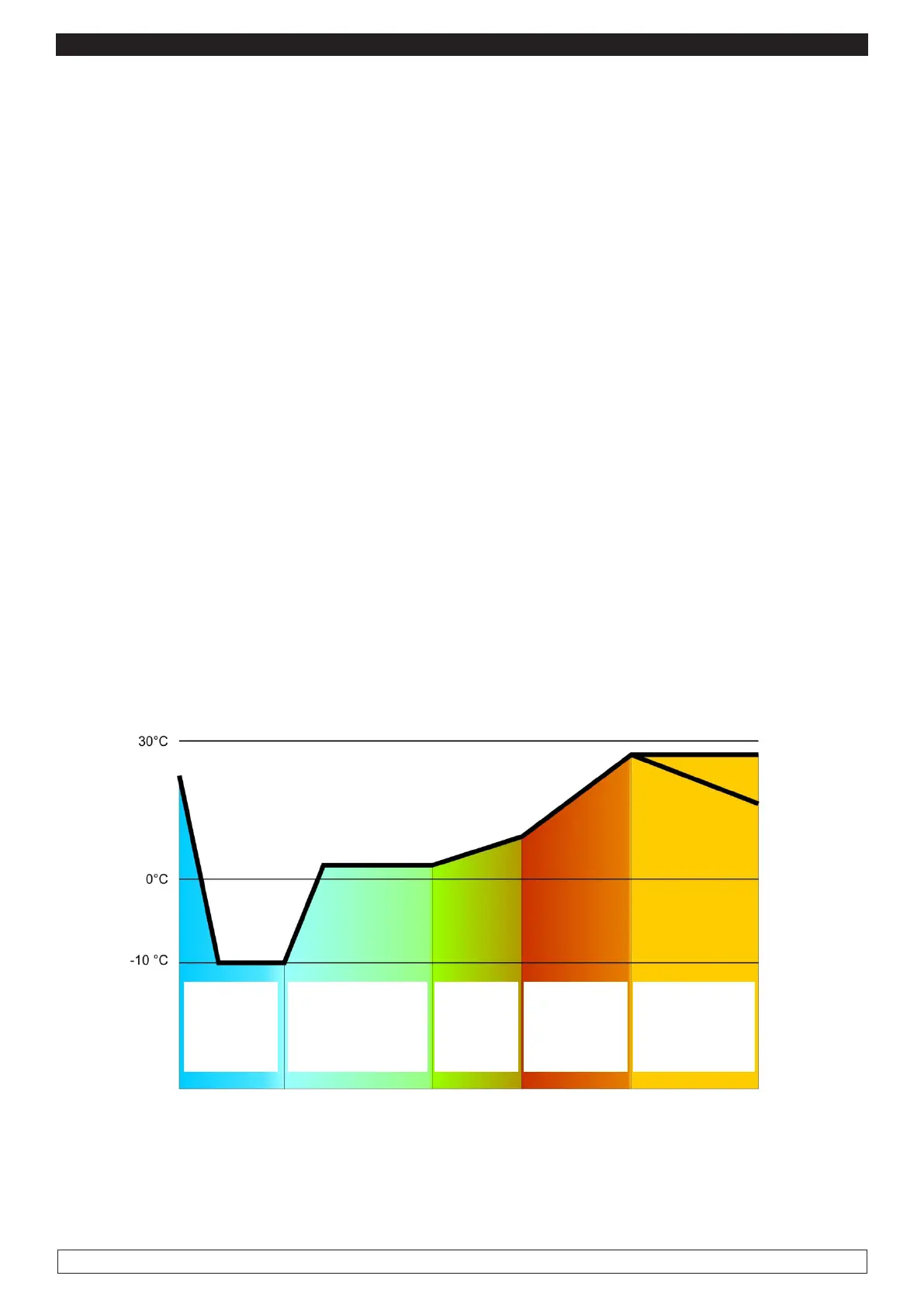

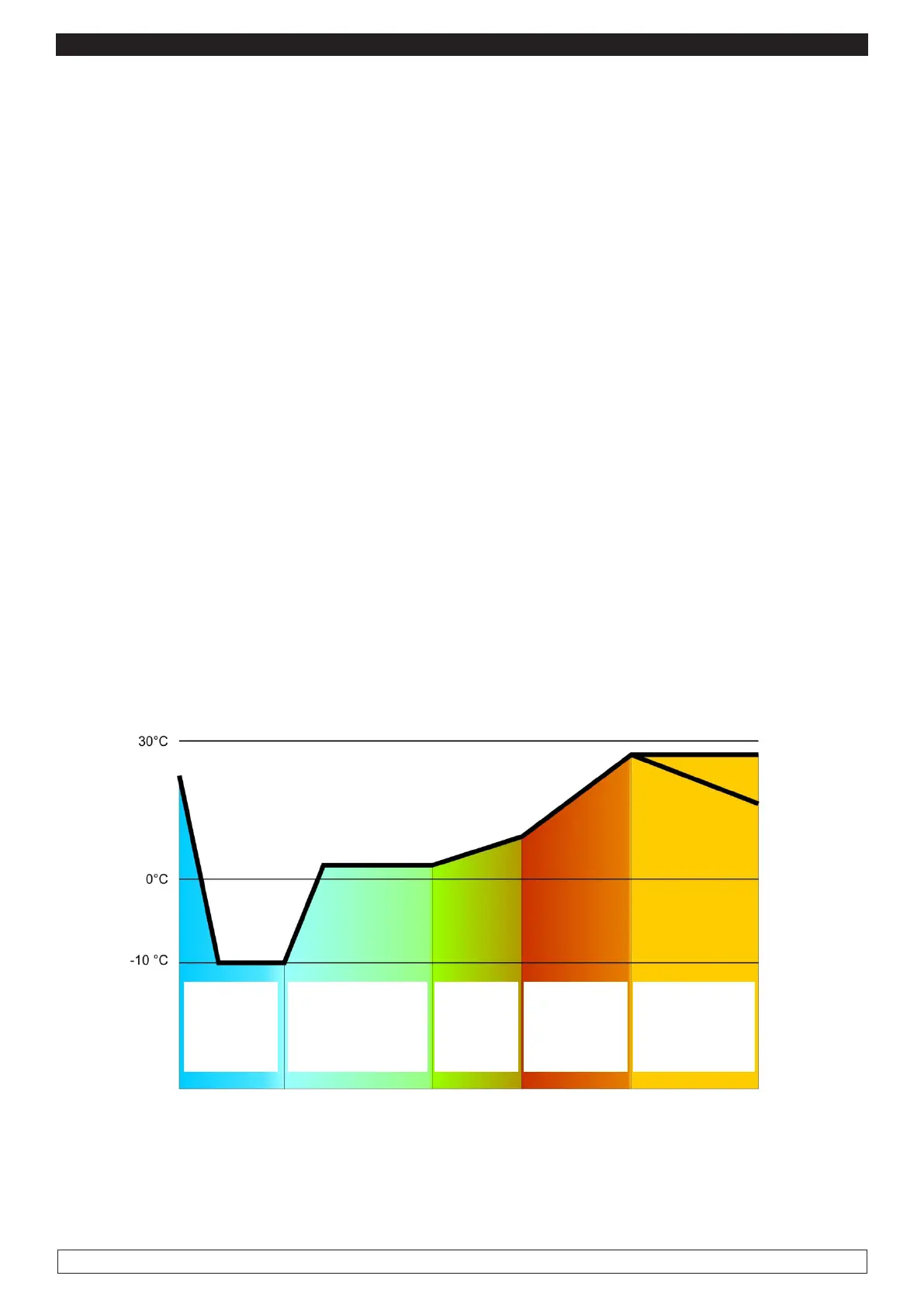

The control panel provides full control for retarder-proofer cabinets or tables for confectionery and

bakery, through the automatic management of the complete retarder-proofing cycle Example

START

MACHINE

END

CYCLE

STOP

MACHINE

COOLING

-5° / -10 °C

--- % r.H.

4-6 ore

STORAGE

-2° / +2 °C

--- % r.H.

changeable time

PROOFING

+10° / +13 °C

70 - 80 % r.H.

1 - 5 ore

LEAVENING

+25° / +30 °C

85 - 90 % r.H.

2 - 4 ore

DELAYED

BAKING

INF+25° / +30 °C

85 - 90 % r.H.

no limit of time

Loading...

Loading...