12 -

BOLT TORQUE CHART

FASTENER TORQUES

Mounting bolts and fasteners may tend to work loose during operation due to vibration or stress. A

visual check of the complete mower should be made daily. All fasteners should be checked for cor-

rect retention torque, weekly, and more often if the unit is being operated in rough areas.

All locally procured fastening hardware should be Grade 5 or equivalent. Use the following chart

for general torque specifi cations for Grade 5 standard fasteners. Special fastener torques for the

mower are shown separately below.

NOTE: All torque specifi cations apply to plated or oiled fasteners. When non-plated or dry fasteners

are used, increase specifi ed torque values by 20%.

IMPORTANT:

Torque values SHOULD NOT be followed when fastening plastic parts!

SPECIAL FASTENER TORQUES

IMPORTANT:

DO NOT use the pulley nut to hold the shaft from turning during blade tightening, as the

pulley nut will be over torqued which could cause spindle spacer and bearing damage.

Mowing Blade Retaining Bolt - (5/8-11 x 1-1/2) ....................... 60 ft. lbs. (81 Nm)

Spindle Pulley Retaining Nut (3/4-16 HEX) ............................ 90 ft. lbs. (122 Nm)

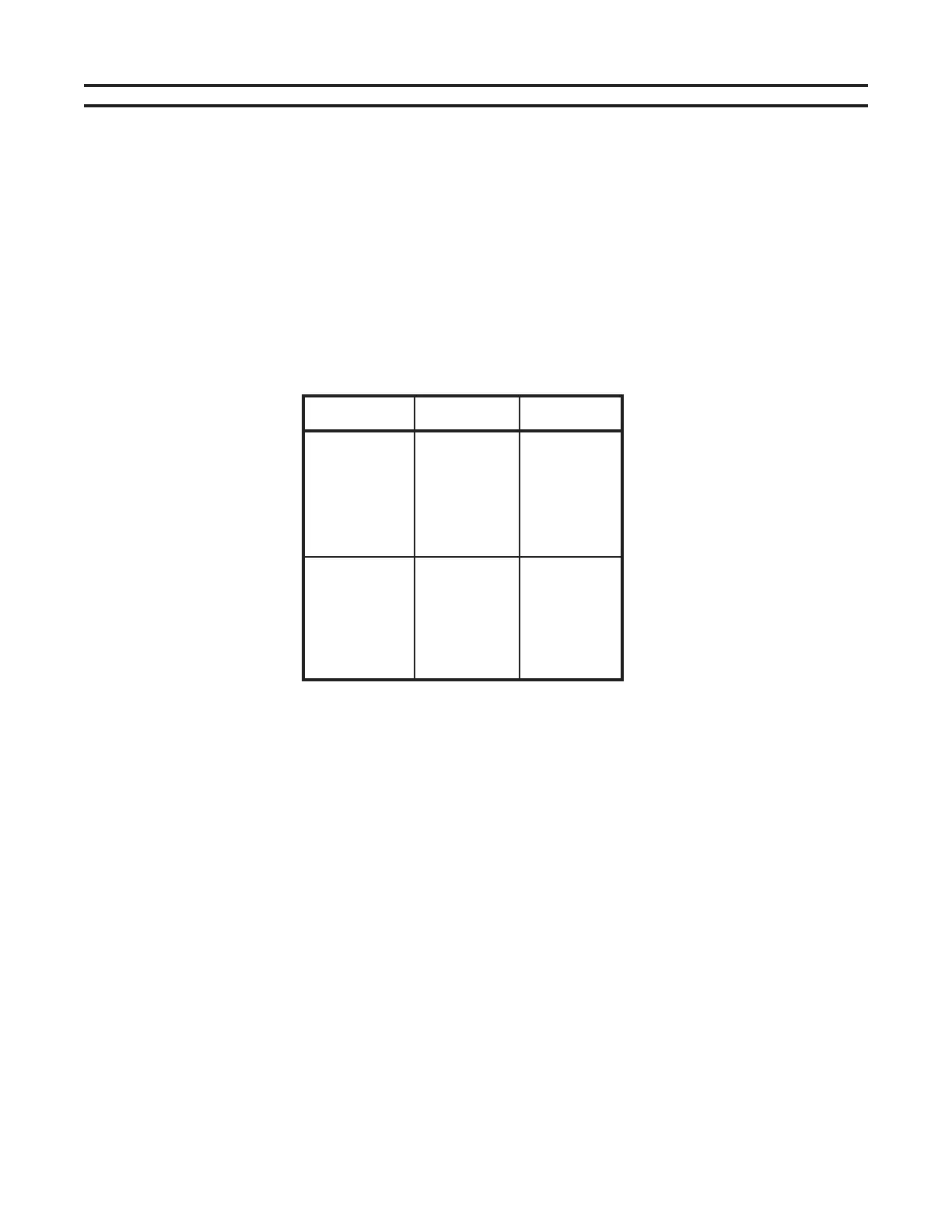

Bolt Size

ft. lb.

N

.

m

1/4-20

5/16-18

3/8-16

7/16-14

1/2-13

9-12

15-20

25-35

40-55

70-90

7-9

10-15

20-25

30-40

50-60

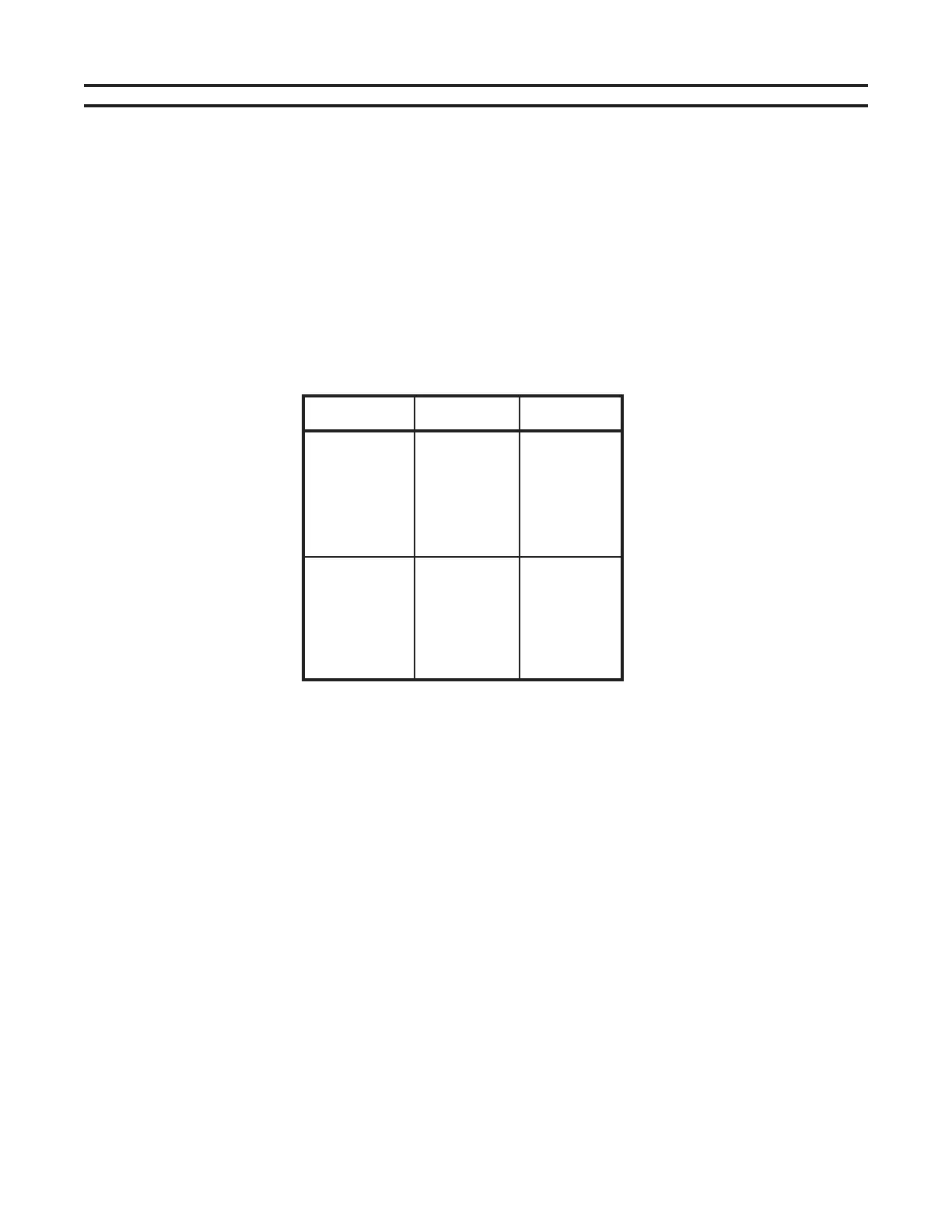

M8

M10

M12

M14

M16

23-27

45-55

75-90

125-145

196-225

17-20

34-40

55-65

91-109

145-166

Loading...

Loading...