48 - Maintenance

PROPELLER

IMPORTANT: Apply

Triple-Guard

grease to the en-

tire propeller shaft before installing the propeller. At

least annually, remove the propeller and check for

debris. Clean the shaft and regrease it before rein-

stalling a propeller.

Installation

Slide thrust washer onto shaft with shoulder facing

aft.

Slide propeller onto shaft, engaging the splines and

seating it on the thrust bushing.

Slide spacer onto the shaft and engage the propel-

ler shaft splines.

Wedge a block of wood between the propeller

blade and the anti-ventilation plate.

100 FPL, FSL, and 115 FPL, FSL models

Install Propeller nut and tighten to a torque of 120

in. lbs. (14 N·m).

Continue to tighten propeller nut until nut slots and

cotter pin hole are aligned. Install new cotter pin

and bend ends to secure.

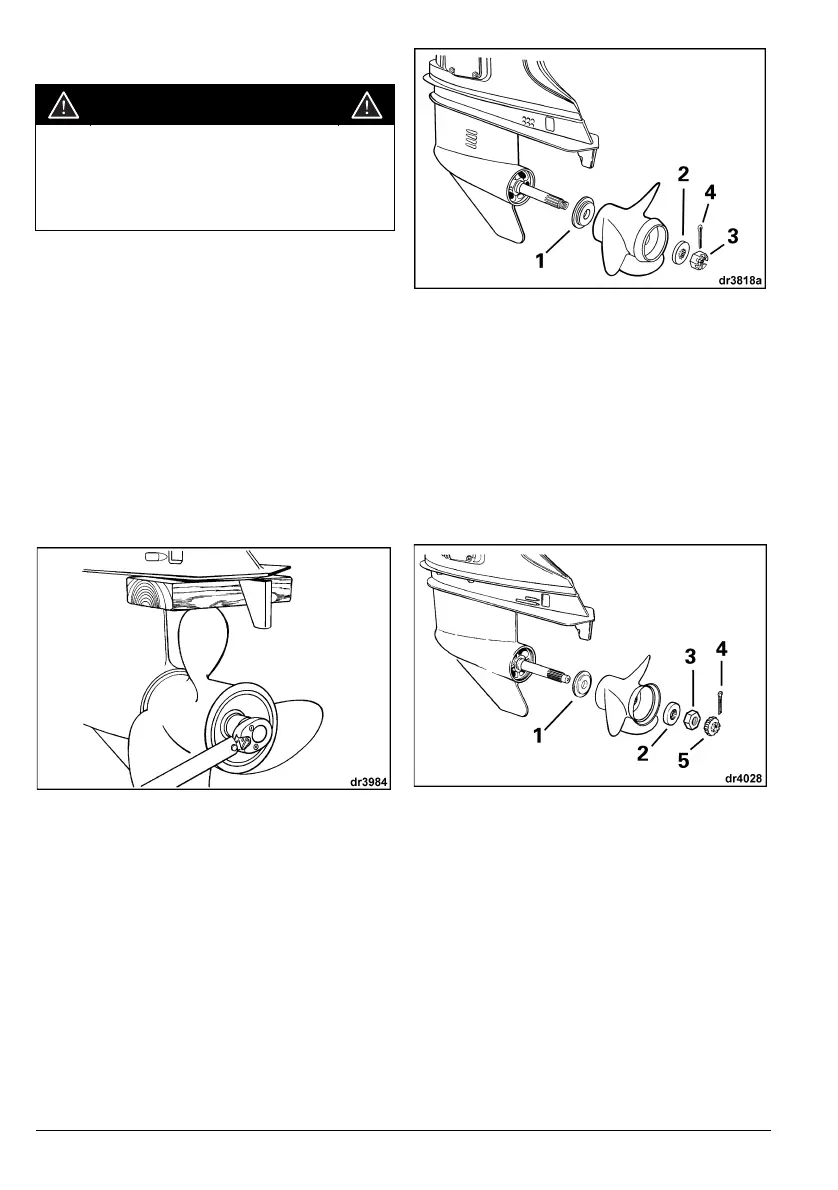

100 FPL, FSL, and 115 FPL, FSL models

1. Thrust washer

2. Spacer

3. Propeller nut

4. Cotter pin

All other models

Install propeller nut and tighten to a torque of 70-80

ft. lbs. (95-108 N·m).

Install keeper on propeller nut, align keeper slots

and cotter pin hole.

Install new cotter pin and bend ends to secure.

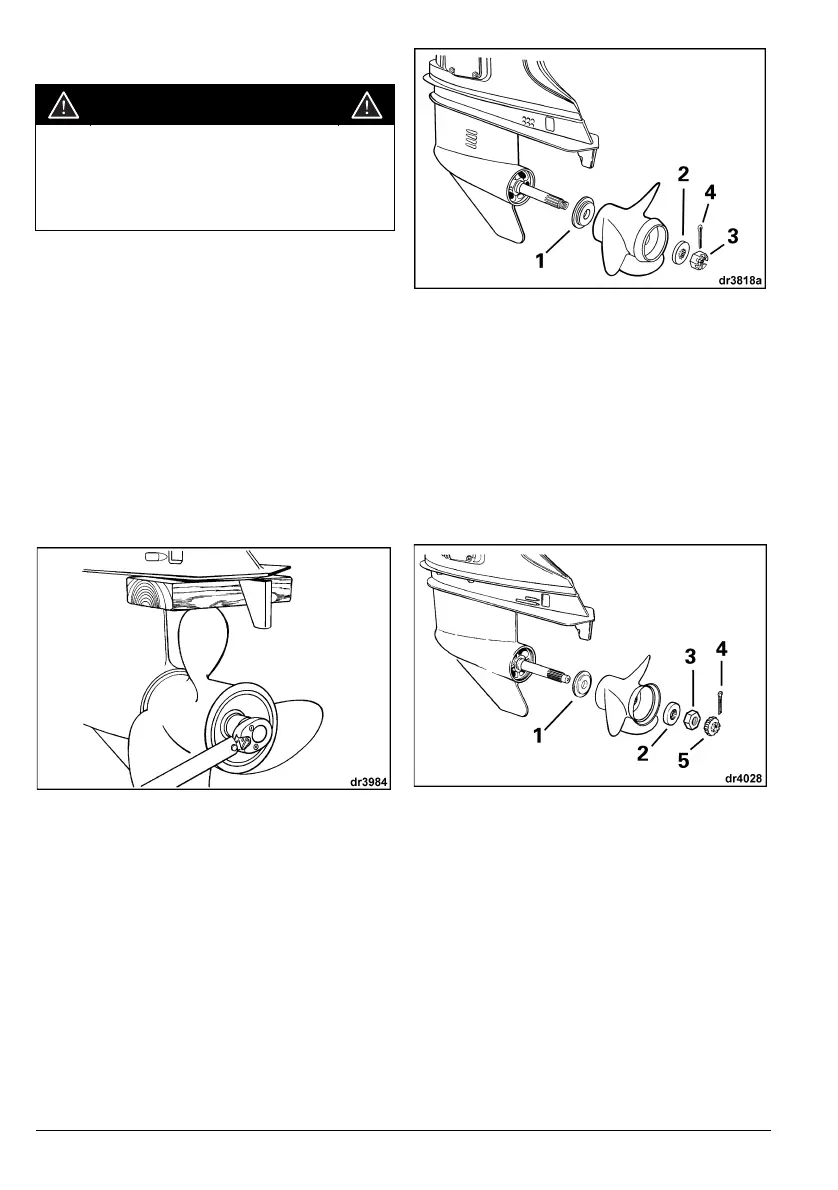

All other models

1. Thrust Washer

2. Spacer

3. Propeller nut

4. Cotter pin

5. Keeper

Remove block of wood. Make sure engine is in

NEUTRAL; give propeller a spin. It must turn freely.

WARNING

When servicing the propeller, always shift

the outboard to NEUTRAL position, turn the

key switch OFF and disconnect battery pos-

itive (+) cable so the engine cannot be

started accidentally.

Loading...

Loading...