EVO42

15

www.evolutionsteel.com

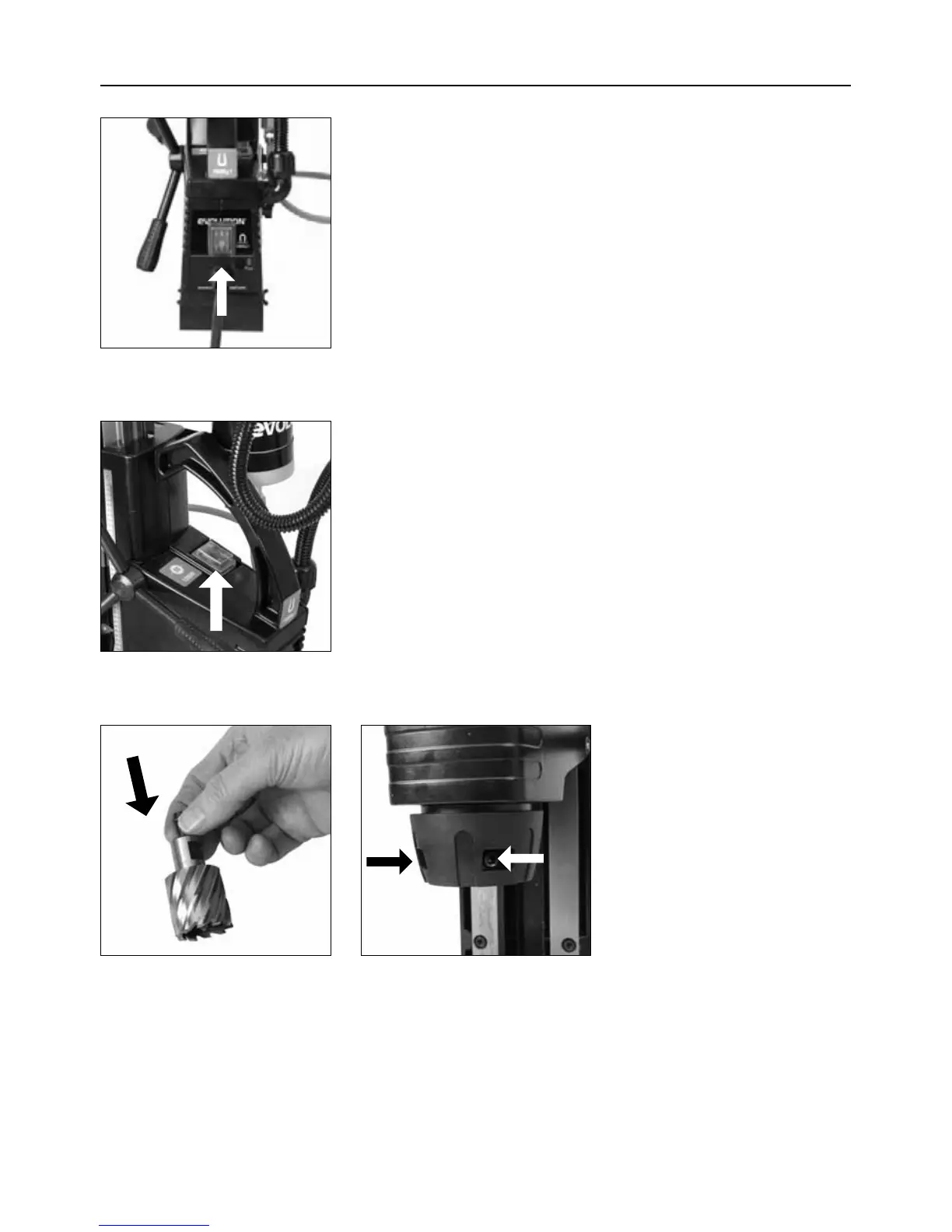

• OperatetheRed switch (Fig. 4) situated at the rear of the

machine to energise the magnet.

• CheckthatthemachineisrmlyattachedtotheMildSteelplate.

• OperatetheBlack motor switch located on

the top of the machine. (Fig. 5)

• Allowthemotortorunforafewsecondstocheckforany

unusual noise or vibration.

• Donotusethemachineifanyvibrationorunusualnoisesare

detected or if magnetic adhesion is questionable. Have the

machine serviced by a qualified person, or if under guarantee

refer to the guarantee agreement.

• Turn‘OFF’themachinewhenalltestinghasbeencompleted.

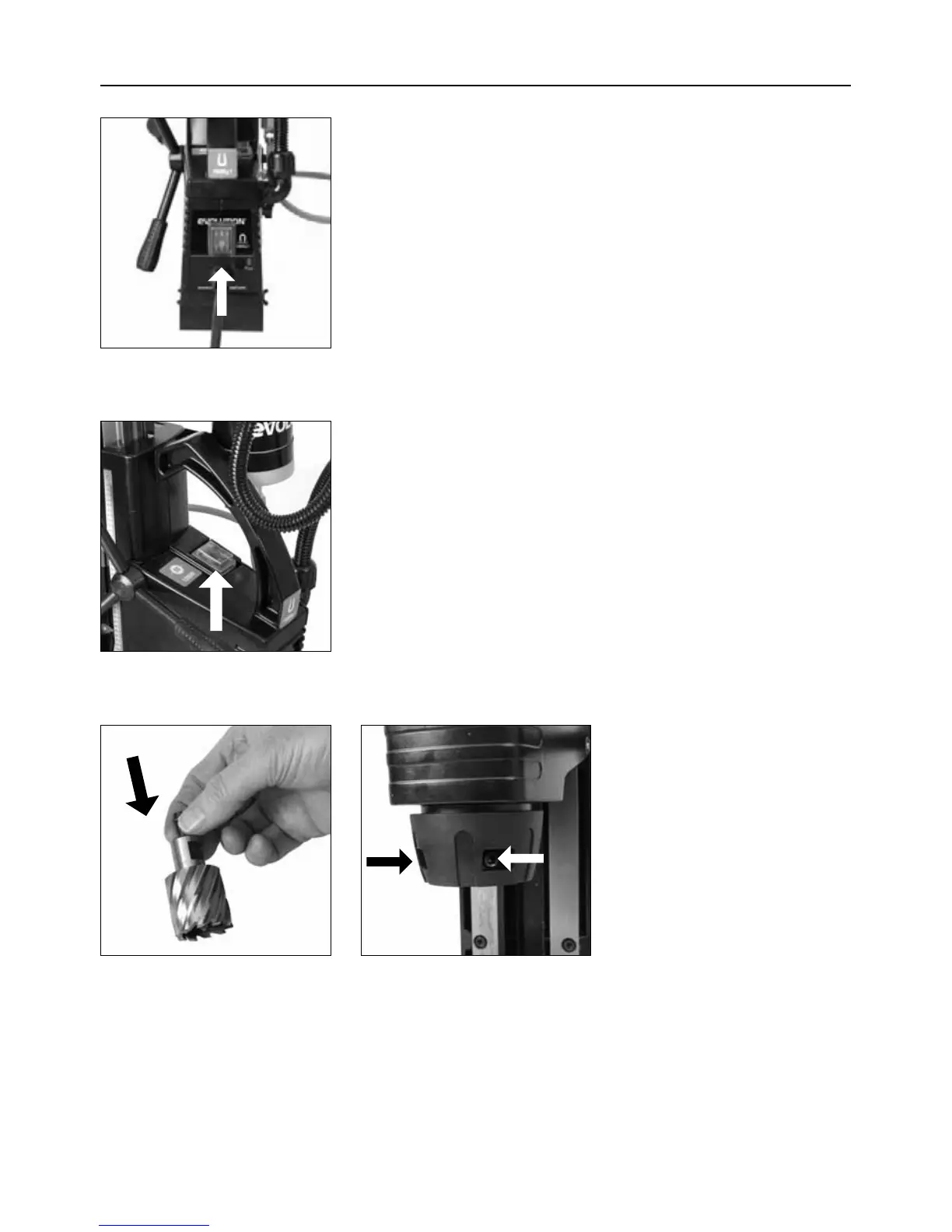

INSTALLING A CUTTER

Selectacuttersuitablefortheoperationtobeperformed.Check

the cutter to ensure that it is sharp and is not damaged in any way.

• Insertthepilotpinintothecutterensuringthat

it slides smoothly. (Fig.6)

• Raisethecuttingheadtoitshighestposition.

• Checkthatthecuttersecuringgrubscrewslocatedinthe

spindle are not protruding into the spindle bore. (Fig.7)

• Alignthetwoatsonthecuttershaftwith

the grub screws in the spindle.

• Starttotightenoneofthegrubscrewsandatthesametimeslightly

rotate the cutter backwards and forwards until the grub screw is fully

tightened. This will ensure that the grub screw is located squarely

onto the flat preventing the cutter from becoming loose.

• Tightentheremaininggrubscrew.

Fig. 4

Fig. 5

Fig. 6 Fig. 6

Loading...

Loading...