14

www.evolutionsteel.com

ASSEMBLY and PREPARATION

WARNING: This machine must not be connected to

a power source until all assembly and preparation has

been completed and a safety check carried out.

Assembly

Removethemachinefromthecaseandcheckthatallaccessories

are present and correct. Place the machine onto a clean, sturdy

work surface.

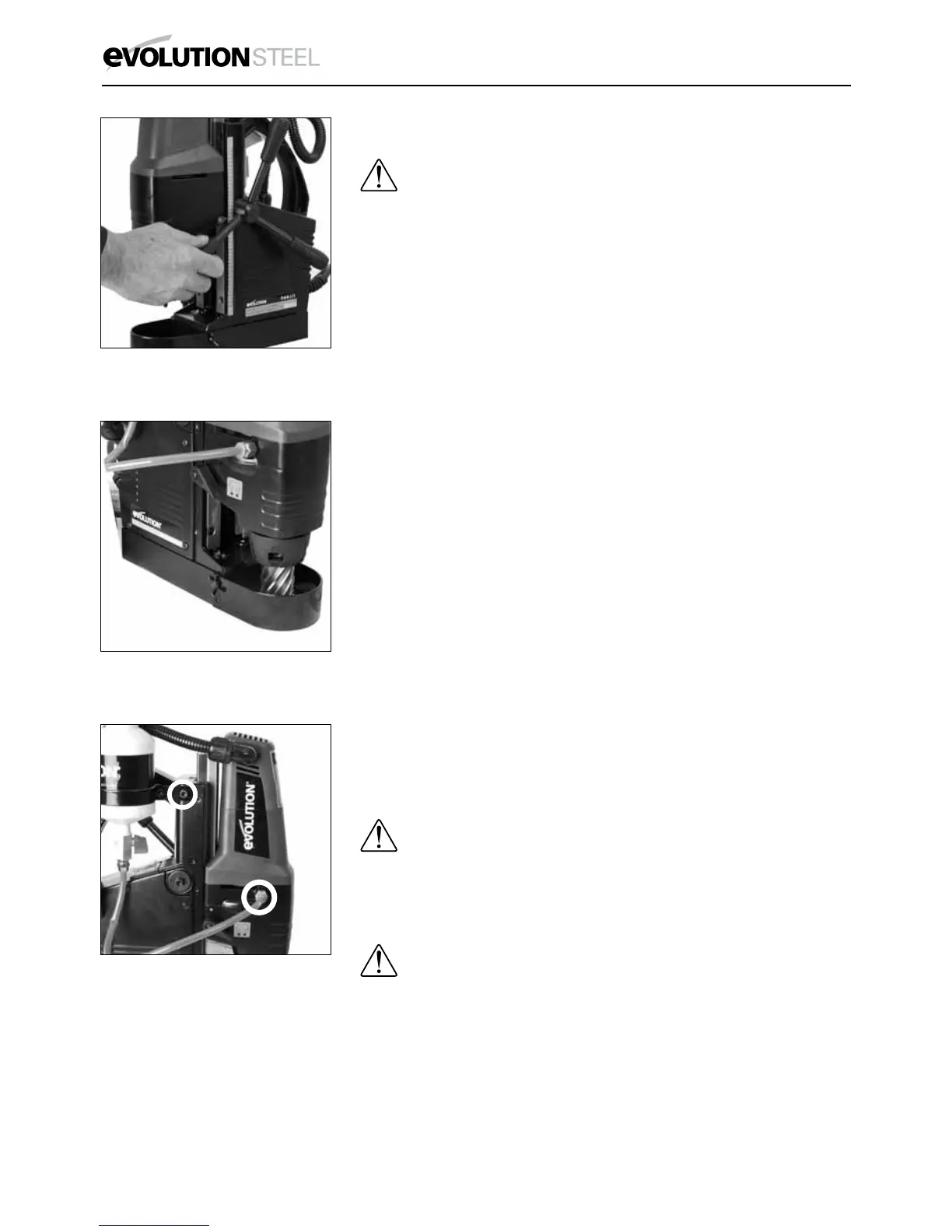

• Attachthethreehandlesintothespindlebossensuringthatthey

are screwed fully home. (Fig. 1)

• AttachtheSafetyGuardandsecureinplaceusingthesupplied

fixing screws. (Fig. 2)

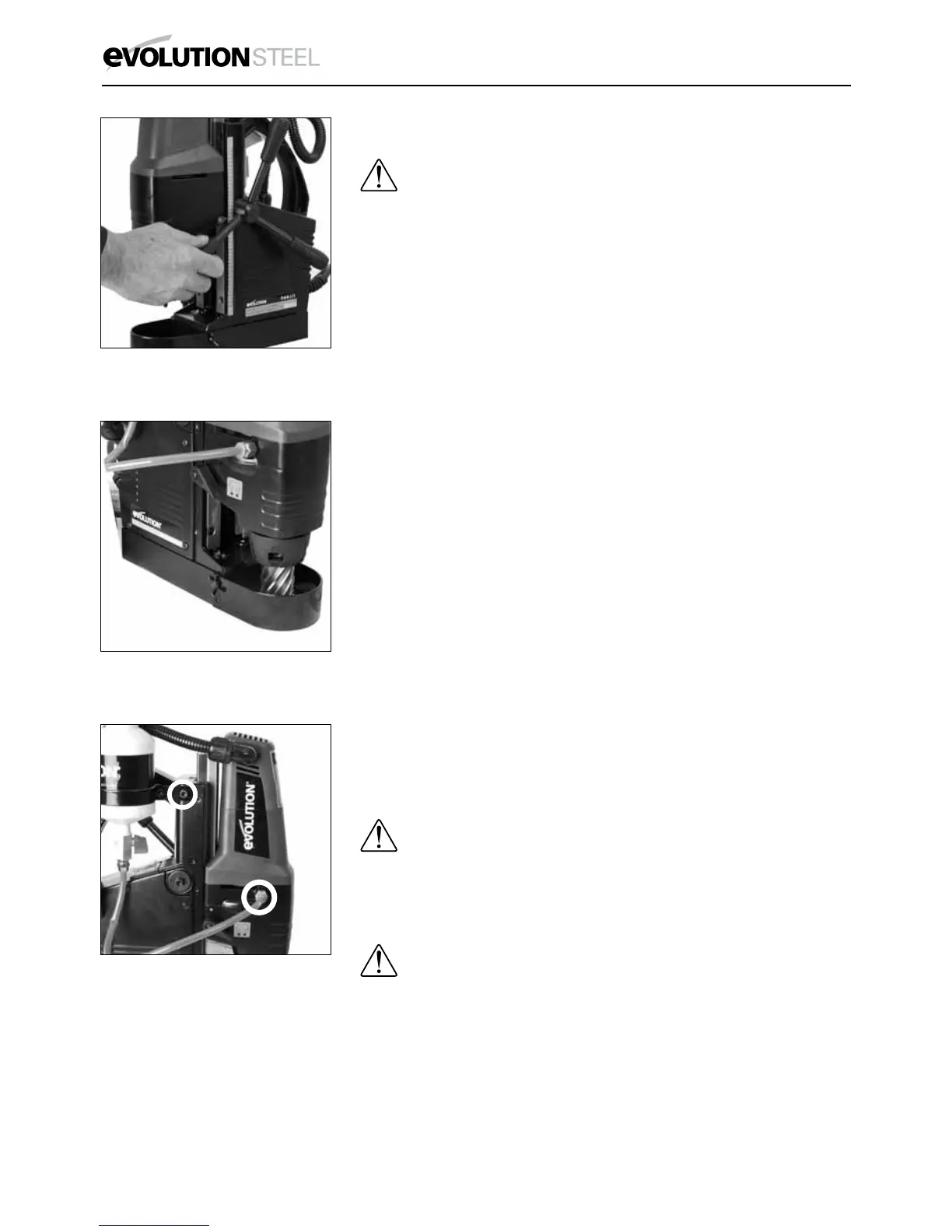

• Thecoolantsystemshouldbefastenedtothemachine

using the ø 6 mm (1/4”) socket headed screw inserted into

the threaded hole located at the top Left Hand side of the

machines carriage. (Fig. 3 a)

• Screwthelubricationquickconnectorintothethreadedhole

located just below the motor housing on the left hand side of

the machine. (Fig. 3b)

• Insertthefreeendofthedeliverypipeintothequickconnector.

Note: To release the delivery pipe from the quick connector push

the collar towards the brass union and withdraw the delivery pipe

Note: For some operations it may be convenient to remove

the coolant tank and supply pipe, and to use alternative coolant

application methods.

OPERATING INSTRUCTIONS

TESTING

WARNING: ThismachinehasCLASS1insulationand

MUST be earthed. Any power socket that this machine

is connected to must be grounded to earth. Ensure that both

operating switches are in the ‘OFF’ position before connecting the

power cord to the socket.

WARNING: The power cord assembly is a custom terminated

one.Replacementshouldonlybecarriedoutbyaqualied

technician. Only use replacement parts recommended by Evolution

Power Tools.

• Placethemachineontoapieceofclean10mmthickMildSteel

plate that is larger than the magnetic base of the machine.

• Connectthe13Aplugintoa13Amainssupplysocket(UK Only).

• Switchonthesocket.

Fig. 1

Fig. 2

Fig. 3

b

a

Loading...

Loading...