12 13

www.evolutionpowertools.com www.evolutionpowertools.com

6. FOOTPLATE ANGLE ADJUSTMENT

Note: The footplate is factory set and adjusted so that the blade

cuts at 90

0

to the footplate.

The footplate may be tilted to an angle of up to 45

0

to either side with

positive location stops at 15

0

, 30

0

and 45

0

.

To adjust the footplate:

WARNING: Disconnect the jigsaw from the power supply before

attempting to adjust the footplate.

• Unclip the plastic footplate shoe and store safely for future

installation. (Fig. 6)

• Withdraw the Dust Extraction Adaptor tube, if tted, and store

safely for future installation. (Fig. 7)

• Loosen the socket headed screw that holds the footplate to the

machine. (Fig. 8)

• Tilt the footplate to the desired angle. To engage one of the

positive stops it will be necessary to slide the footplate backwards

or forwards depending upon the stop required.

• Tighten the socket-headed screw carefully so as not to damage

the threads.

• Re-install the Dust Extraction Adaptor tube.

• Refit the plastic footplate shoe ensuring that all six (6)

securing lugs (2 to the front of the footplate and 2 either side)

are correctly seated.

Note: The positive location stops are intended as a guide only. For

accurate setting of the footplate we recommend the use of a vernier

angle gauge (not supplied).

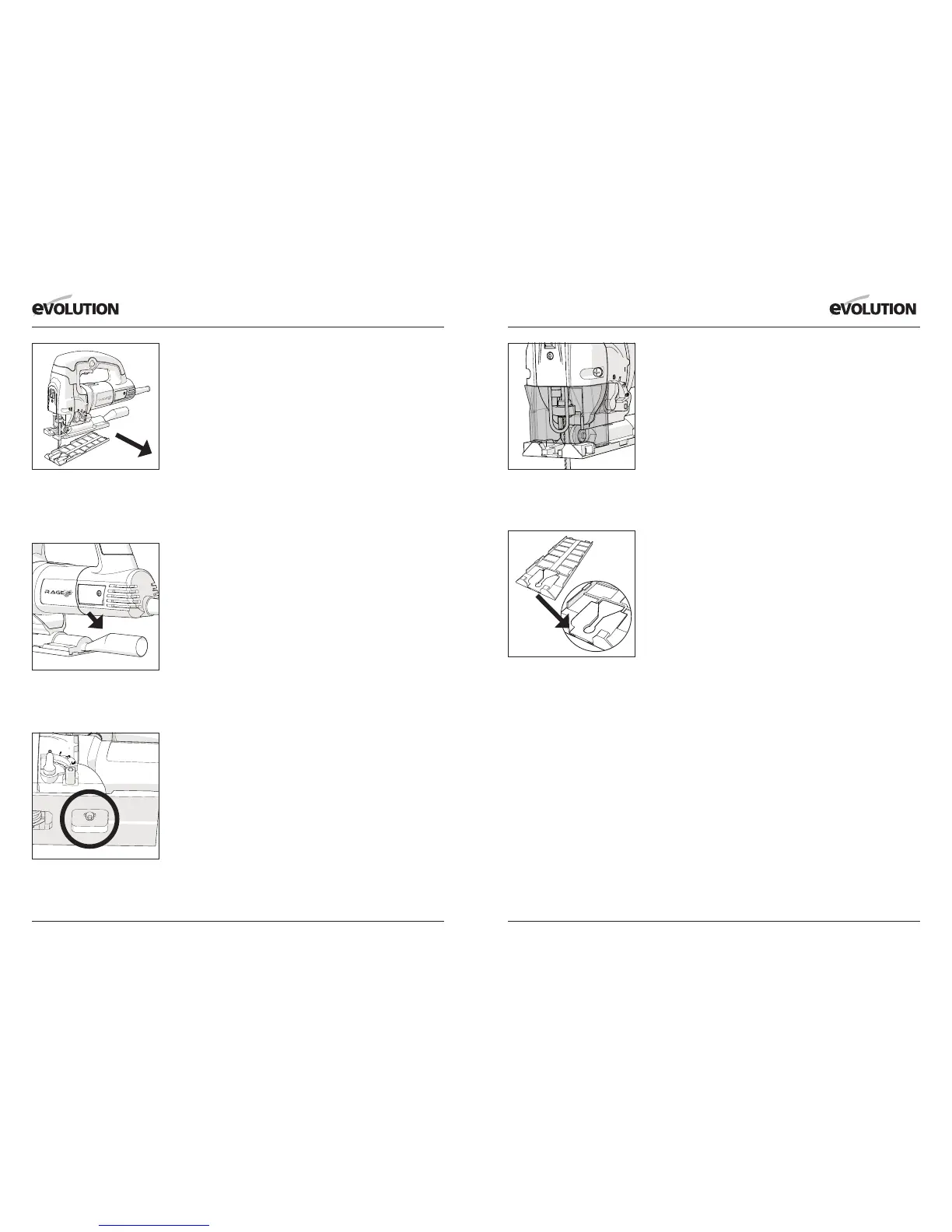

Fig 6

View of footplate shoe being

unclipped and removed from

footplate.

Fig 7

View of Adaptor tube in service

position.

Fig 8

Close up view of socket headed

screw.

7. CHIP GUARDS

Two (2) plastic chip guards are provided. The Front Chip Guard

should always be tted and the Footplate Chip Guard can be tted

to the machine as and when required.

To t the Front Chip Guard:

• Ensure that the machine is disconnected from the power supply

• The front guard (Fig. 9) clips over the front of the machine, below

the laser guide and in front of the steel blade guard.

Note: This guard is precisely engineered and designed to just clip

into place. There is sufcient ‘spring’ in the design to allow the guard

to be carefully positioned into its service position. The operator

should use care and ensure that the guard is not ‘forced’ into place

with the attendant risk of damage to the guard. Seat the guard

carefully in its service position.

The Footplate Chip Guard (Fig. 10) can be useful when cutting long

straight lines. The use of this guard will help prevent the sawblade

from swinging during a cut.

To t the Footplate Chip Guard:

• Ensure that the machine is disconnected from the power supply.

• Unclip the plastic Footplate Shoe from the Footplate.

• Clip the Footplate Chip Guard into the inside of the Footplate

Shoe with the ‘Vee’ pointing towards the rear of the shoe, and the

raised platform positioned within the throat of the shoe. Ensure

positive location within the shoe. The guard should lie ‘ush’ with

both surfaces of the shoe.

• Carefully replace the Footplate Shoe with the attached Chip

Guard onto the Footplate.

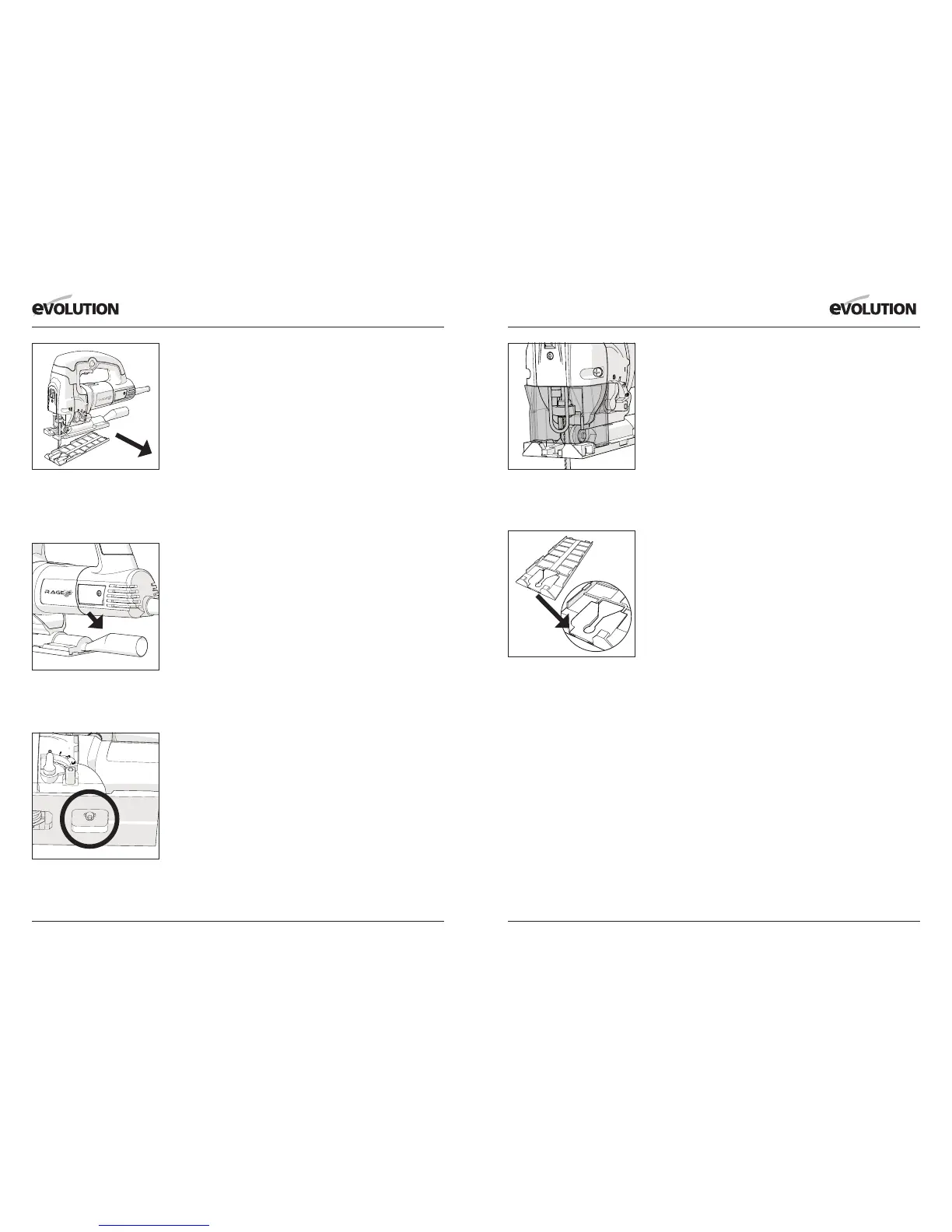

Fig 10

Close up view of Footplate

Guard in service position before

installation of footplate shoe.

Fig 9

Close up view of Front

Guard in service position.

Loading...

Loading...