9

4. Drill pilot holes of the appropriate diameter and depth for the

screws you will be using at all screw locations.

5. Firmly secure the Faceplate to the blank by driving screws

through all mounting holes in the Faceplate.

6. Fit the Spindle Washer onto the Headstock Spindle and then

thread the Faceplate with mounted blank onto the Spindle.

7. Release the Tailstock Lock Lever and slide the Tailstock until

the tip of the Live Center almost touches the blank. Press the

Tailstock Lock Lever to lock down the Tailstock.

8. Carefully turn the Quill Handwheel to advance the Live

Center. Once the tip of the Live Center makes contact,

continue tightening the Quill Handwheel to make sure

the Live Center is seated.

9. Loosen the Banjo Lock Lever and the Tool Rest Lock Handle.

Slide the Tool Rest Banjo into position, making sure that no

part of the workpiece will contact the Tool Rest once the lathe

is turned on. Lock the Banjo Lock Lever.

10. Adjust the Tool Rest up or down to your preferred height for

the task and engage the Tool Rest Lock Handle. Again, spin

the workpiece by hand to make sure no part of it will contact

the Tool Rest.

Maintenance

> Vacuum dust and debris from lathe regularly. Keep

Lathe Bed clean.

> If rust appears on cast iron Lathe Bed, carefully remove

with steel wool or other fine abrasive. Coat exposed iron

surface with Boeshield T-9

®

Rust and Corrosion Protection

to prevent rust from developing again.

> Before each use, check lathe components, including Drive Belt,

to ensure all are in proper working condition.

> Follow the manufacturer’s guidelines for proper use of any

rust prevention chemical. Dispose of any excess chemicals in

accordance with manufacturer’s instructions and as required

by law.

Replacing the Drive Belt

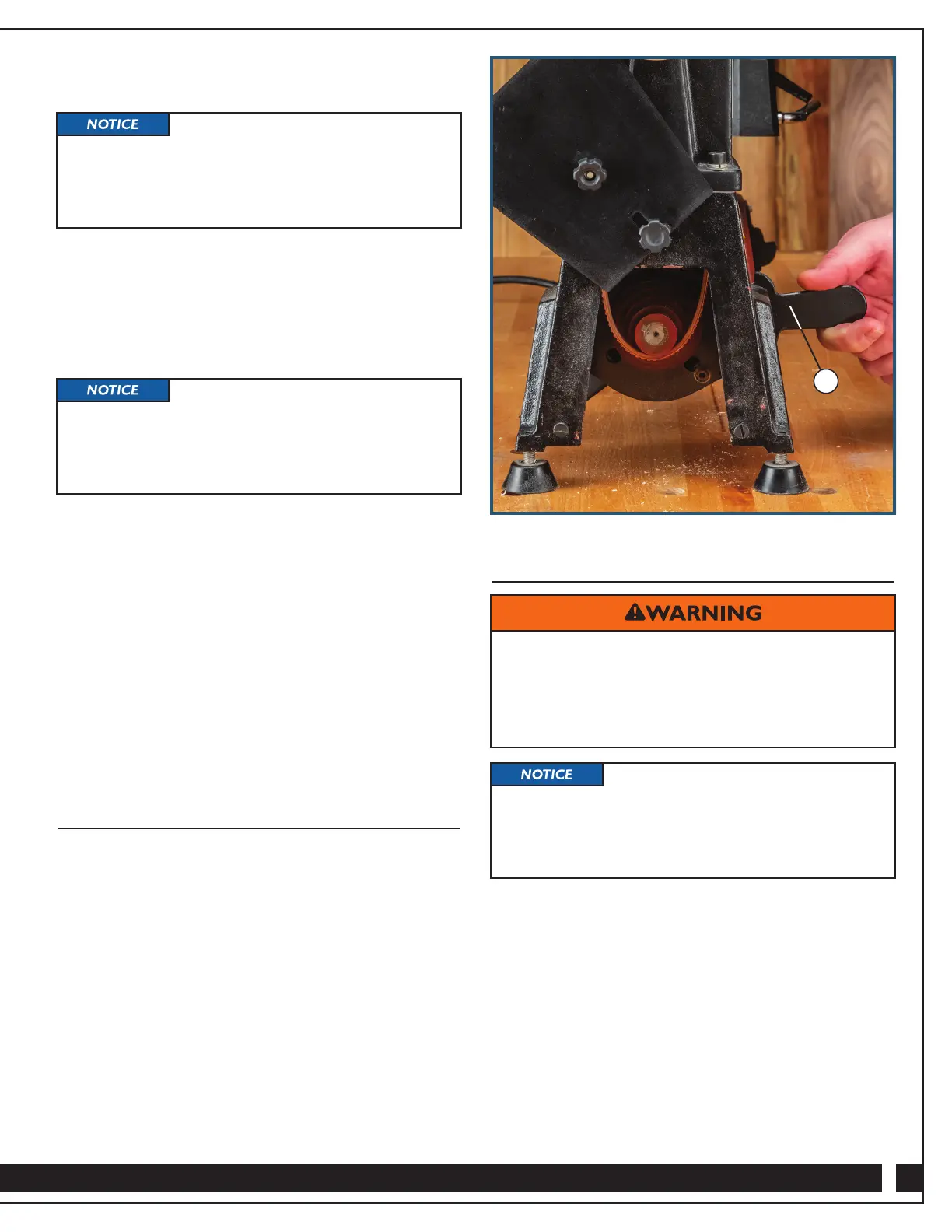

1. Loosen the Moving Knob (57), lift and swing the Side Belt

Access Cover (23) up under the Headstock Wheel (22) and

Tighten the Moving Knob to secure it there and provide

access to the Motor Pulley (29).

2. Follow the same process to swing the Rear Belt Access

Cover (20) up and secure it to obtain access to the

Drive Pulley (25).

3. Loosen the Belt Tension Lever Lock Handle (33) and lift the

Belt Tension Lever (31) to allow slack on the Drive Belt (26).

Fig. 3.

> Disconnect the tool from the power source before

servicing or before changing accessories.

> Always close and secure both the Side Belt Access

Cover and the Rear Belt Access Cover before turning

on the lathe.

Use steel pan-head or washer-head

screws to hold your blank to the Faceplate. The screws

need to be long enough to provide a strong bite on the

blank but shorter than the final depth of the recess you will

turn inside the bowl or platter. Typically, you want screws

at least 1" long.

Use the part numbers listed on the

Parts Diagram on pages 11 and 12 to identify parts

described in this section.

> Excelsior Mini Lathe Replacement Belt is available from

Rockler (29424, sold separately).

Use steel pan-head or washer-head

screws to hold your blank to the Faceplate. The screws

need to be long enough to provide a strong bite on the

blank but shorter than the final depth of the recess you will

turn inside the bowl or platter. Typically, you want screws

at least 1" long.

Fig. 3

31

Loading...

Loading...