CHAPTER 51

PAGE 24

EXT

RA - FLUGZEUGBAU GmbH

SERVICE MANUAL EXTRA 200

PAGE DATE: 1. July 1996

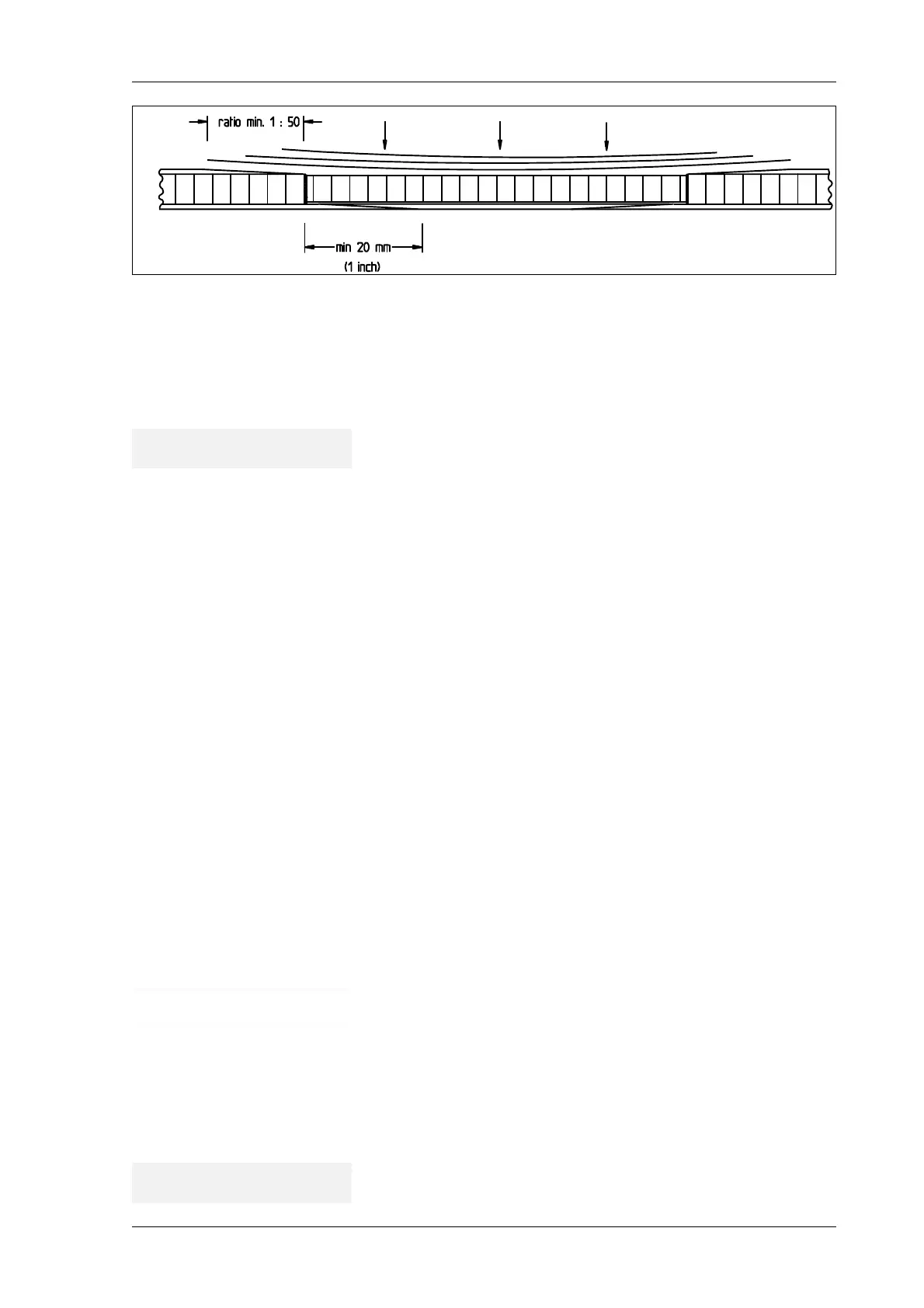

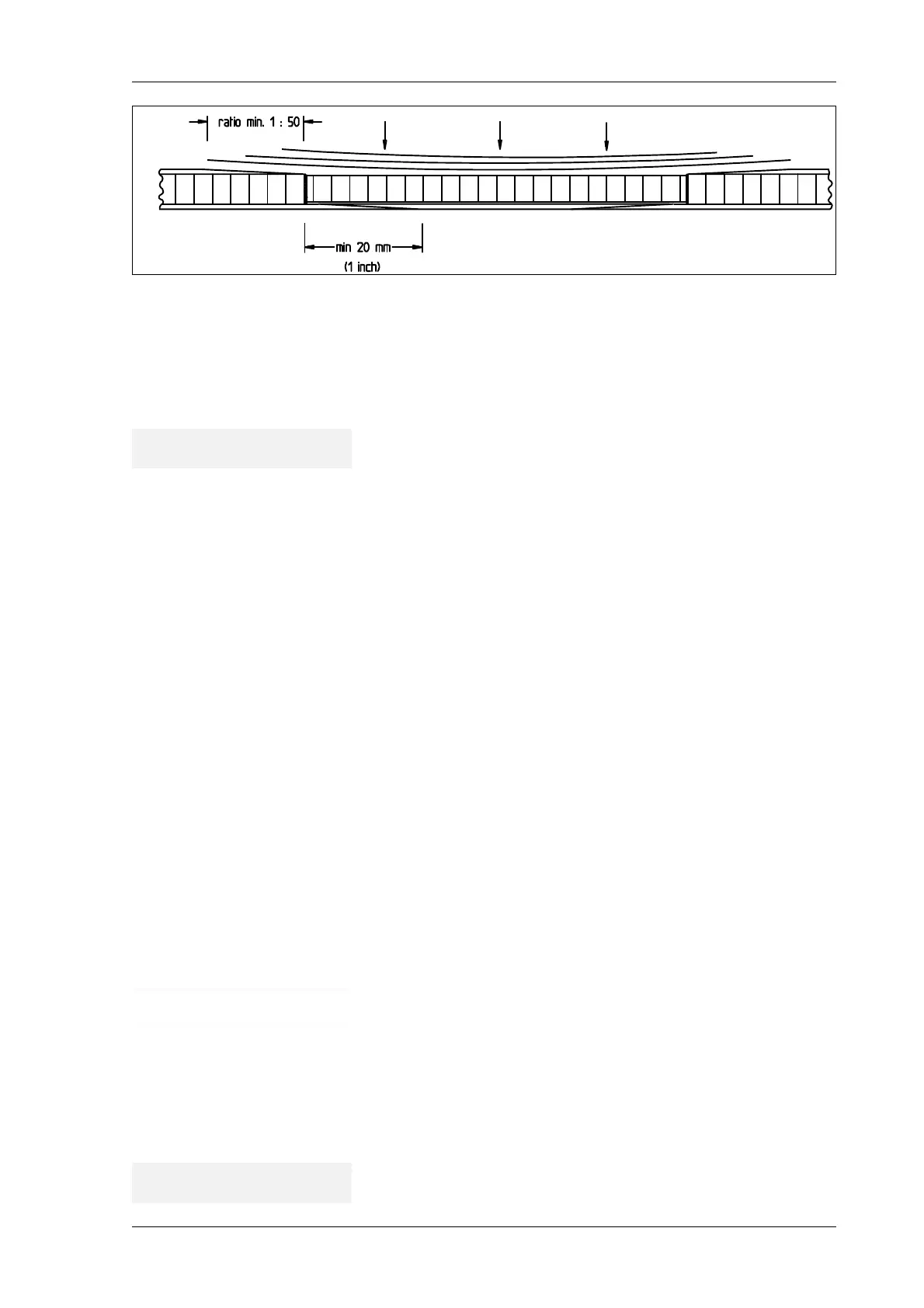

Damage of Complete Sandwich

Figure 8

Lay out the required number and size of fabric pieces on a

piece of plastic foil and wet them with resin mixture.

Subsequently position them on the repair area.

I M P O R T A N T Remove the plastic foil after each positioning process.

The repair area has to be cured under condition of vacuum

bagging. Proceed as follows:

- Apply peel nylon fabric on the last repair fabric layer

- Perforate a clean, thin plastic foil with a thick needle

(max. spacing of holes: 20mm x 20mm) - mainly in the

area of the honeycomb - and lay it on the repair area.

- Lay a jute cloth or equivalent bleeder cloth on this

perforated plastic foil

- Lay a second plastic foil upon the jute weave and seal

their edges to the surrounding surface using an adhesive

tape.

- Apply suction with a vacuum pump (pressure approx.

0.7bar / 10psi)

- Apply the thermal curing cycle

- Following the curing cycle carefully remove vacuum

bagging material and peel nylon fabric.

N O T E After the pre-curing period at room temperature, the

repaired area has to be cured according the tempera-

ture cycle as shown on Figure 6.

After the curing process is completed, the repair area can be

sand level to the surrounding area.

I M P O R T A N T Sand only the edge thickness of repair laminate!

REPAIRS

Repair of Sandwich Material

Loading...

Loading...