Page E-16

Repair and Service Manual

B

FRONT SUSPENSION AND STEERING

Read all of Section B and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

turned fully to the right forcing passenger spindle arm

against front axle.

Set proper rack extension-to-rack and pinion unit clear-

ance. See “Spindle Contact with Front Axle” on page E -

16.

Install front wheels per WHEELS AND TIRES section

and lower vehicle per SAFETY section.

Check front wheel alignment and adjust if necessary.

See “Wheel Alignment” on page E - 3.

Checking/Adjusting Rack Extension-to-Rack

and Pinion Unit Clearance

Tool List Qty.

Wrench, 11/16” ............................................................ 1

Wrench, 3/4" ................................................................ 1

Wrench, 1/2" ................................................................ 1

Wire Cutter .................................................................. 1

Washer, 1/8” Thick....................................................... 1

Crowfoot Socket, 3/4” .................................................. 1

Torque Wrench, ft. lbs..................................................1

Wire Tie, 10" long ........................................................ 1

Check for proper rack extension-to-rack and pinion unit

clearance by first turning steering wheel fully to the right.

The rear spindle arm on the passenger side must rest

against the front axle (Ref Fig. 20). If it does not, all

adjustment is made at the rack ball joint (6) (Ref Fig.

19). Loosen jam nut (5) at rack ball joint and use wrench

to thread shaft of rack extension (7) further into rack bal-

ljoint. This will provide more travel for the steering wheel

to be turned to the right.

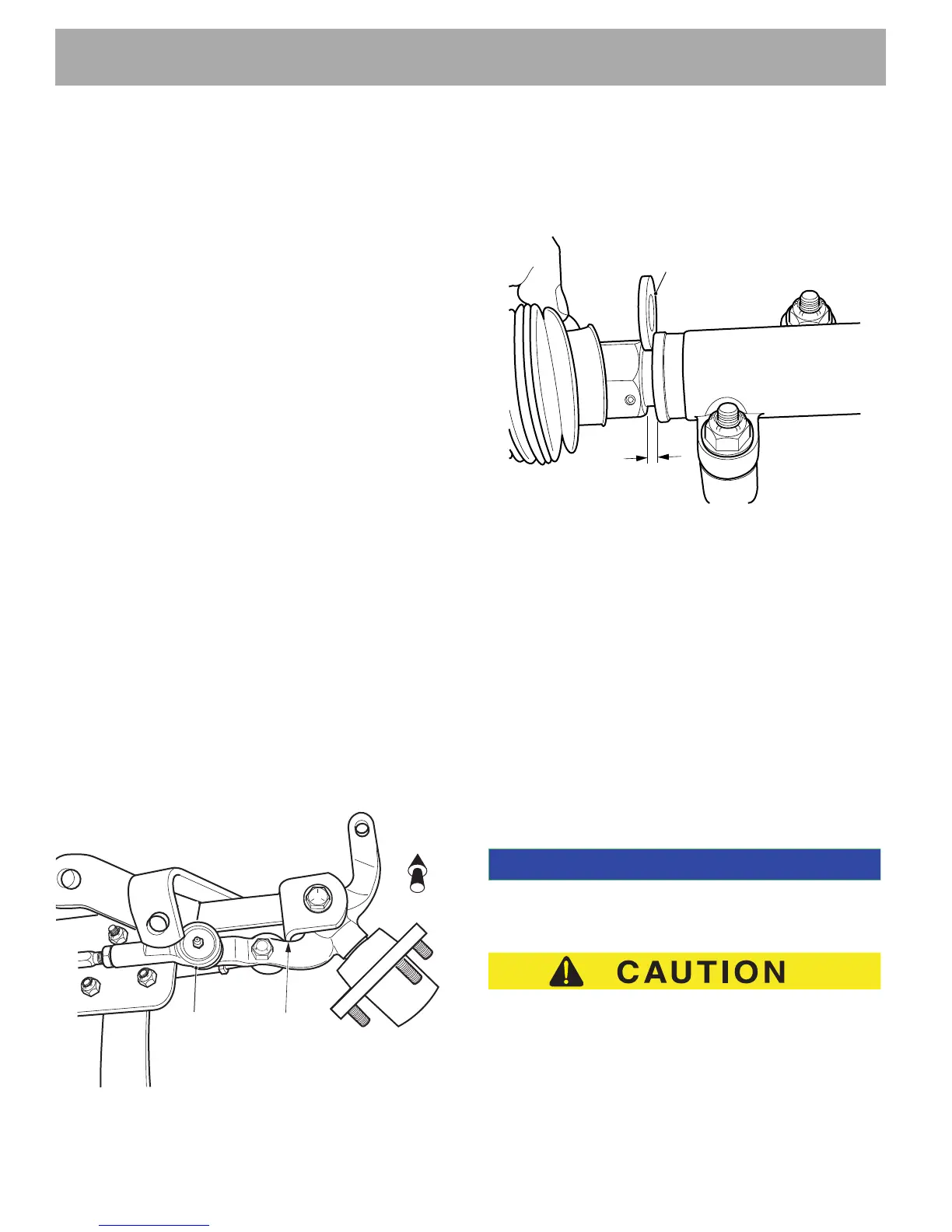

Fig. 20 Spindle Contact with Front Axle

With spindle arm resting against front axle, cut wire tie

(14) securing bellows (9) to rack and pinion unit (1) and

slide bellows away from rack and pinion unit to see large

hex of rack extension. An 1/8” gap should exist between

the large hex and the end of the rack and pinion unit.

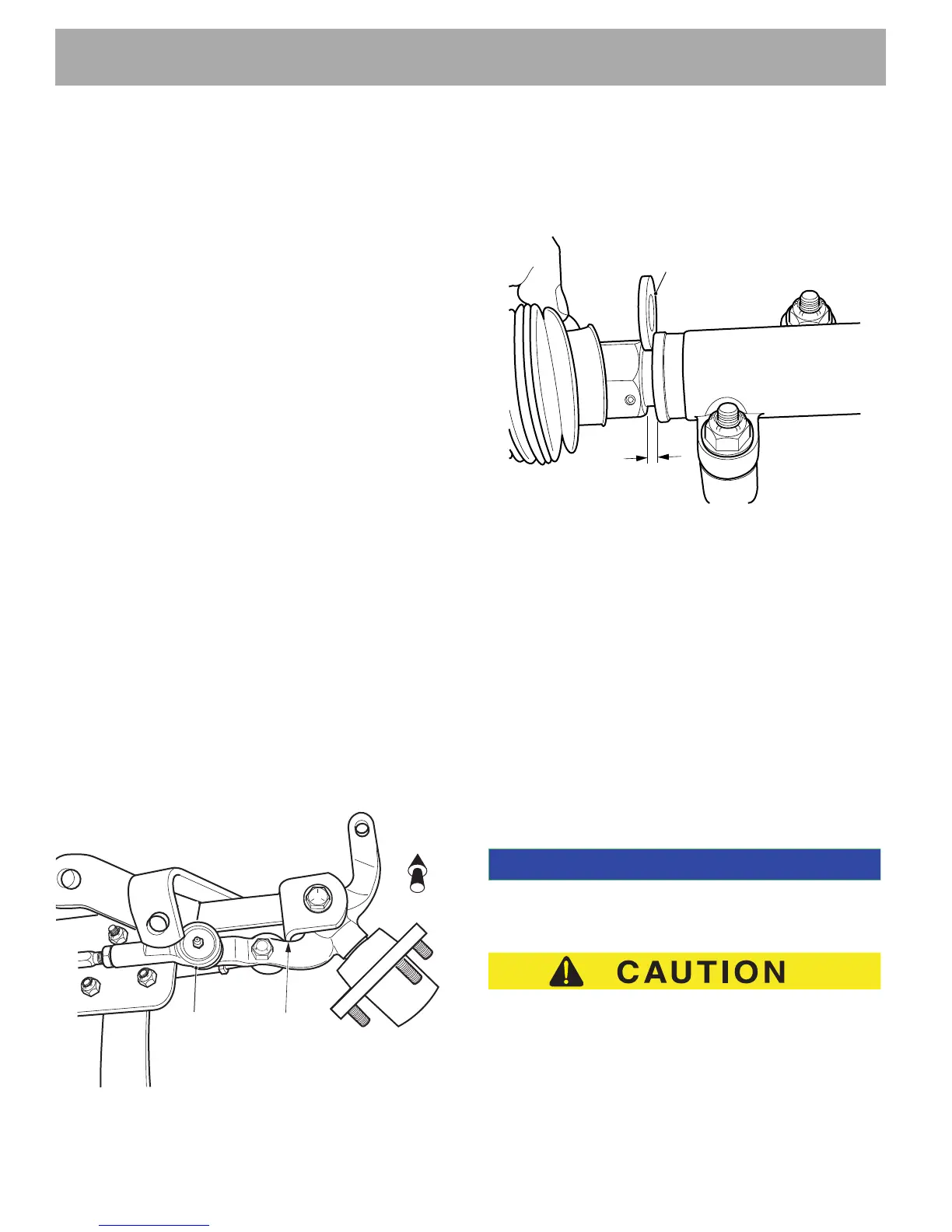

Fig. 21 Checking Gap

Adjust, using an 1/8” thick washer as a gauge, by turning

shaft of rack extension with wrench to create the 1/8”

gap. Tighten jam nut (5) to 35 - 45 ft. lbs. (47 - 61 Nm)

torque. Secure bellows to rack and pinion unit with new

wire tie (14).

Steering Wheel Replacement

Tool List Qty.

Socket, 15/16”..............................................................1

Ratchet, 1/2" drive .......................................................1

Plastic Faced Hammer ................................................1

Ball Peen Hammer.......................................................1

Anti-seize Compound ..................................................1

Torque Wrench, ft. lbs. .................................................1

To maintain correct orientation when replacing steering wheel,

first turn wheels straight ahead.

To prevent damage to the steering wheel cover, perform

the following removal procedure. Do not use a screw-

driver to push or pry the retaining tabs.

From the front side of the steering wheel (1), remove the

steering wheel cover (2) by first pulling straight up on the

bottom of the steering wheel cover to release the two

Passenger Side

Spindle Arm

Resting Against

Front Axle

Rack

Ball

Joint

Front

of Vehicle

Gap

Approximately

1/8" Thick Washer

Loading...

Loading...