TO ENSURE THE PERFECT INSTALLATION AND OPERATION OF THE COMBI 740 ADHERE TO THE FOLLOWING EXPLANATORY POINTS AND RELATIVE DRAWINGS.

IMPORTANT: THE ENTIRE INSTALLATION PROCESS MUST BE CARRIED OUT BY QUALIFIED, TECHNICAL PERSONNEL IN COMPLIANCE WITH EN 12453 - EN 12445

SAFETY STANDARDS, AND IN ACCORDANCE WITH MACHINERY DIRECTIVE 2006/42/CE.

CARRY OUT A CAREFUL ANALYSIS OF RISKS IN ACCORDANCE WITH SAFETY REGULATIONS IN FORCE.

GENERAL INFORMATION:

The COMBI 740 is an oil-hydraulic automated operator designed to open and close swinging gates; it is installed below ground at the

base of the gate's rotation hinges. It is an oil-hydraulic operator with a built-in hydraulic drive unit; the entire operator is housed inside

its enclosure, cemented at the base of the gate leaf. The electronic programmer control is installed externally in a protected area and

it controls all possible movement functions automatically or semi-automatically, depending on the client's requirements.

The gate opener includes a number of accessories that ensure necessary safety and manoeuvrability, making this operator suitable for

installation in any public or private place.

INSTRUCTIONS TO BE FOLLOWED BEFORE INSTALLING THE OPERATOR

PRELIMINARY WARNINGS FOR SAFETY AND GOOD SYSTEM OPERATION

Before installing the operator in the ground, be sure to verify the following:

- Installation, checks, testing, and risk analysis and further maintenance must be carried out by qualified, authorised, technical personnel.

- This automated device was designed for specific use, as indicated in this manual, with safety, control and signalling accessories as

minimum required.

- Any use of the operator which is not explicitly stated in this manual may cause operational disruption or damage to property and people.

- Check the consistency of the soil to avoid settling or subsequent deformation in the installation area.

- Ensure that there are no utility lines in the immediate vicinity or underground which may hinder any digging required.

- Ensure that in the immediate vicinity of installation accessories, both above and below ground, there are no sources of electromagnetic

disturbance that could hide or influence magnetic/electromagnetic readings from any metal loop detectors and from all electronic

control and system management equipment.

- Ensure that the mains power and voltage to the electric motor is 230V±10% 50Hz.

- Combi 740 must be powered with electrical cables having 1mm

2

diameter for a maximum distance of 50 meters. For distances longer

than 50 meters, the use of electrical cables with appropriate diameter wires is recommended.

- For any replacements of parts or accessories, use original components indicated by the manufacturer.

- All packaging materials must be disposed of by specialised companies. Do not throw away, in normal waste receptacles, any material

that may be harmful to the environment.

- Meccanica Fadini is not responsible for any damage caused by improper use, or use not specifically mentioned in this manual, and is

not liable for malfunctions resulting from the use of materials or accessories not provided by the company itself.

- The manufacturer reserves the right to make changes to this manual without prior notice.

!

!

Meccanica Fadini, the manufacturer, is not responsible for installations failing to comply with correct installation and application

technique and for applications not included in this manual.

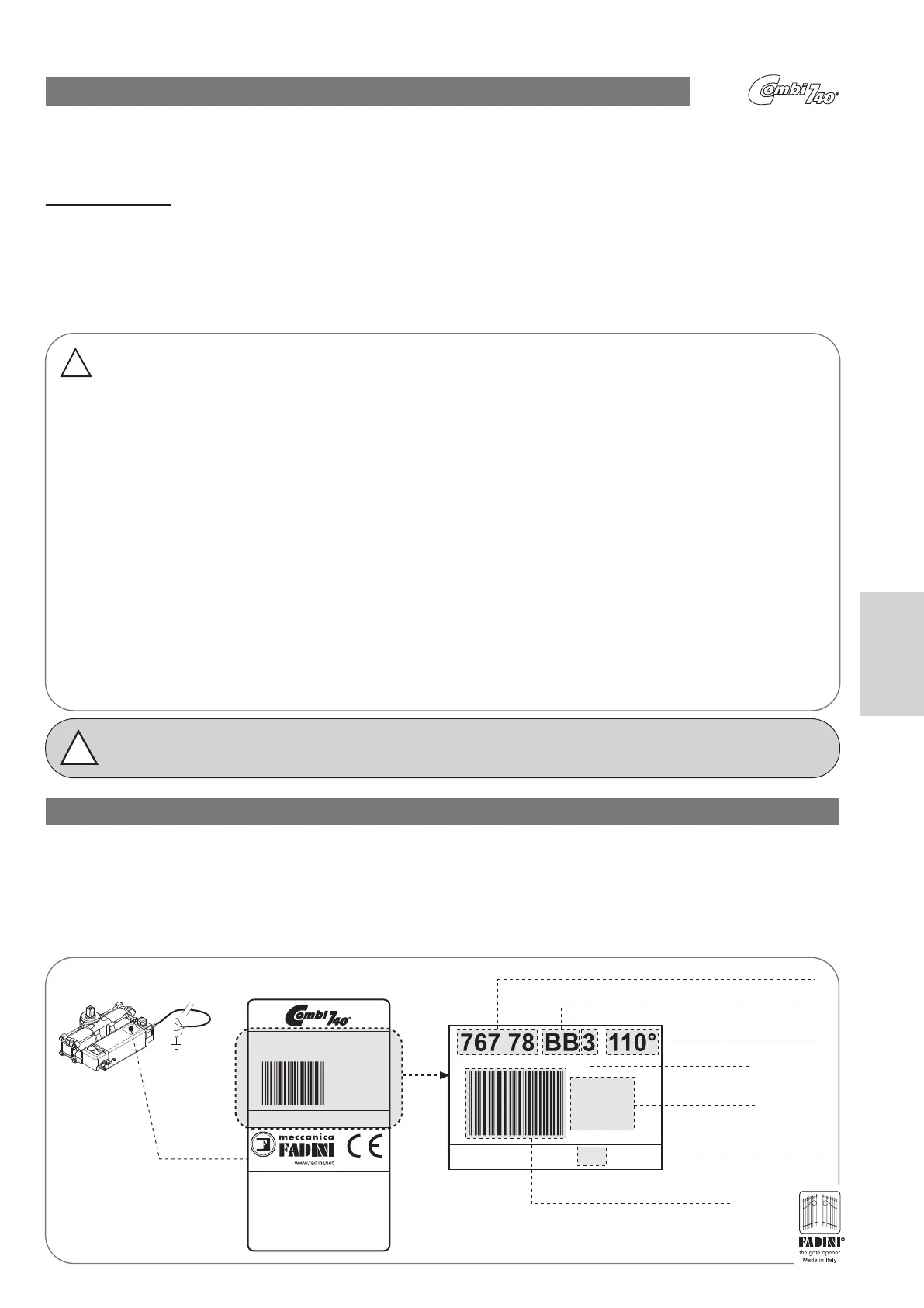

VERSIONS OF THE COMBI 740 OIL-HYDRAULIC OPERATOR

110° Version = underground swing gate opener with 110° maximum leaf rotation.

175° Version = underground swing gate opener with 175° maximum leaf rotation.

Normal version = 110° and 175° non locking in the two movement directions. Use of an electric lock is always recommended.

Locking version = 110° and 175° locking in the two movement directionss.

Version with Brake = 110° and 175° rotation with adjustable hydraulic braking in the two movement directions, during the last 40 cm (approx.) of movement.

Version with Flow Regulator = 110° and 175° rotation with adjustment of hydraulic flow (controls the leaf speed) in the two movement directions for leafs longer than

2.5 meters.

PIC.3

19

English

Combi 740 identification sticker

Item number. Price list refers

767 78 BB3 110°

Freno

Braking

avec Frein

Working 110°

Power

Supply voltage

Absorbed current

Maximum pressure

rpm motor

IP

OIL FADINI

180W (0,25CV)

230V - 50Hz

1,3 A

30 atm

1350

67

-25°C +80°C

made in italy

Freno

Braking

avec Frein

Working 110°

N = non locking in opening

BB = Double Locking

Shaft rotation angle 110° or 175°

Pump type P3

Braking version

Shaft rotation angle 110° or 175°

Bar code

Loading...

Loading...