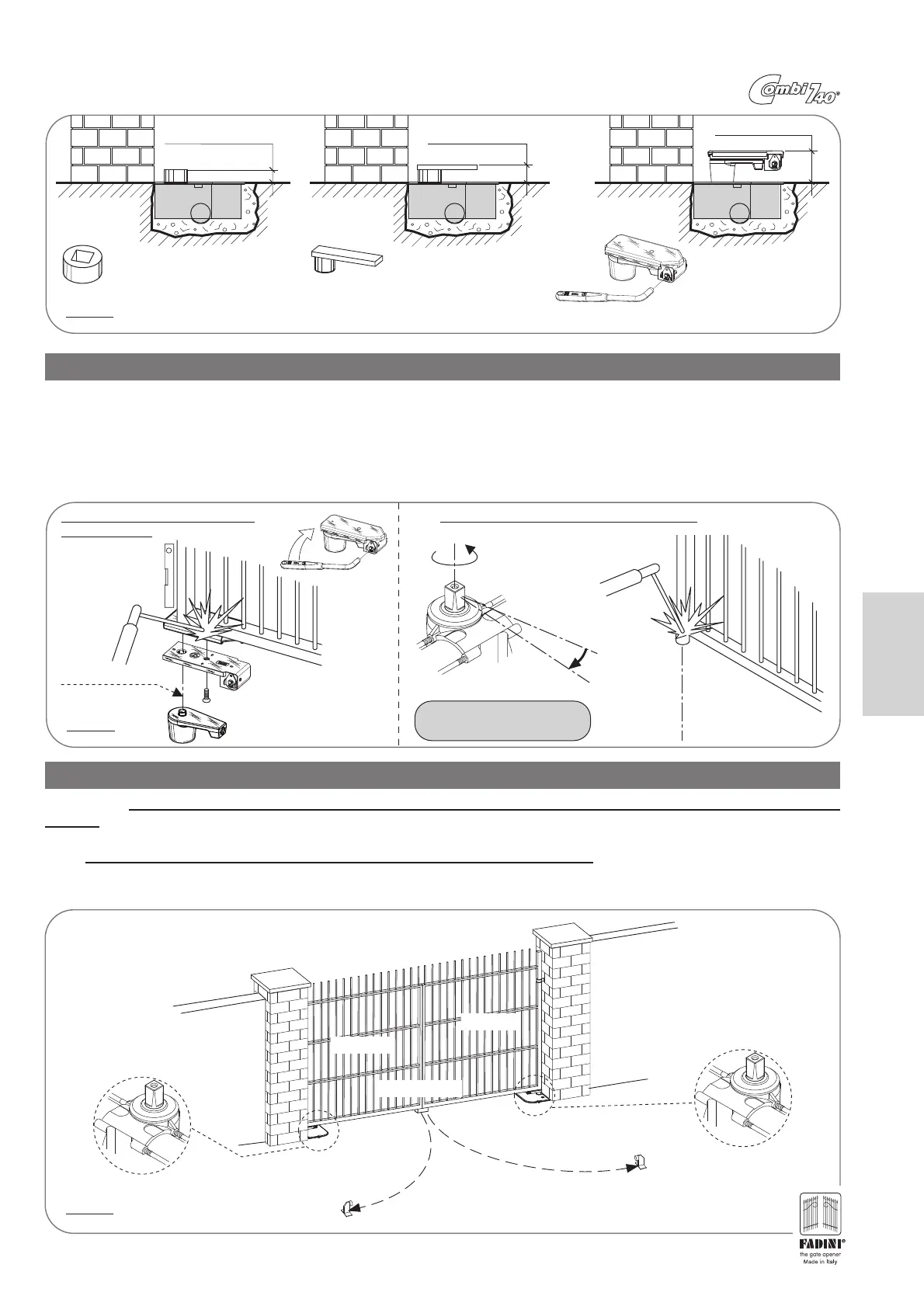

PIC. 13

PREPARING THE LEAF: SECURING THE EMERGENCY RELEASE OR THE FERRULE

After having allowed the concrete to set around the Enclosure, and depending on the application requirements for the leaf to be

operated, the following overall measurements will be obtained (Pic. 13):

Measurement A=30mm

code 761 Ferrule with square hole

Measurement A=42mm

code 746 Ferrule with square hole

with Support plate (Right or Left)

The connection between the gate leaf to be opened and the Combi 740 operator may occur in three possible versions depending on if there is an

emergency manual release system, a simple Support plate with square hole ferrule or only a Square hole ferrule. However, in all cases it is necessary

to tightly weld these three items to the leaf base, in alignment with the upper hinge of the leaf itself (Pic.14).

At this time, the measurement indicated in Pic. 13, between the enclosure and the above leaf becomes important.

IMPORTANT: the Support plate with a square hole ferrule and the single square hole ferrule must be welded to the leaf with the Combi 740 shaft

rotated by 5° or 10°, before it arrives at the end of travel. (Pic.14). (Putting into phase process).

Measurement A=80mm

code 748 Emergency

release with square ferrule,

release key and welding

plate (Right or Left)

Sx

Emergency Manual Release Gate connection: by welding either the ferrule directly or the support plate

Leaf rotation

axle

Level

Leaf rotation

axle

Travel end axle

Leaf axle

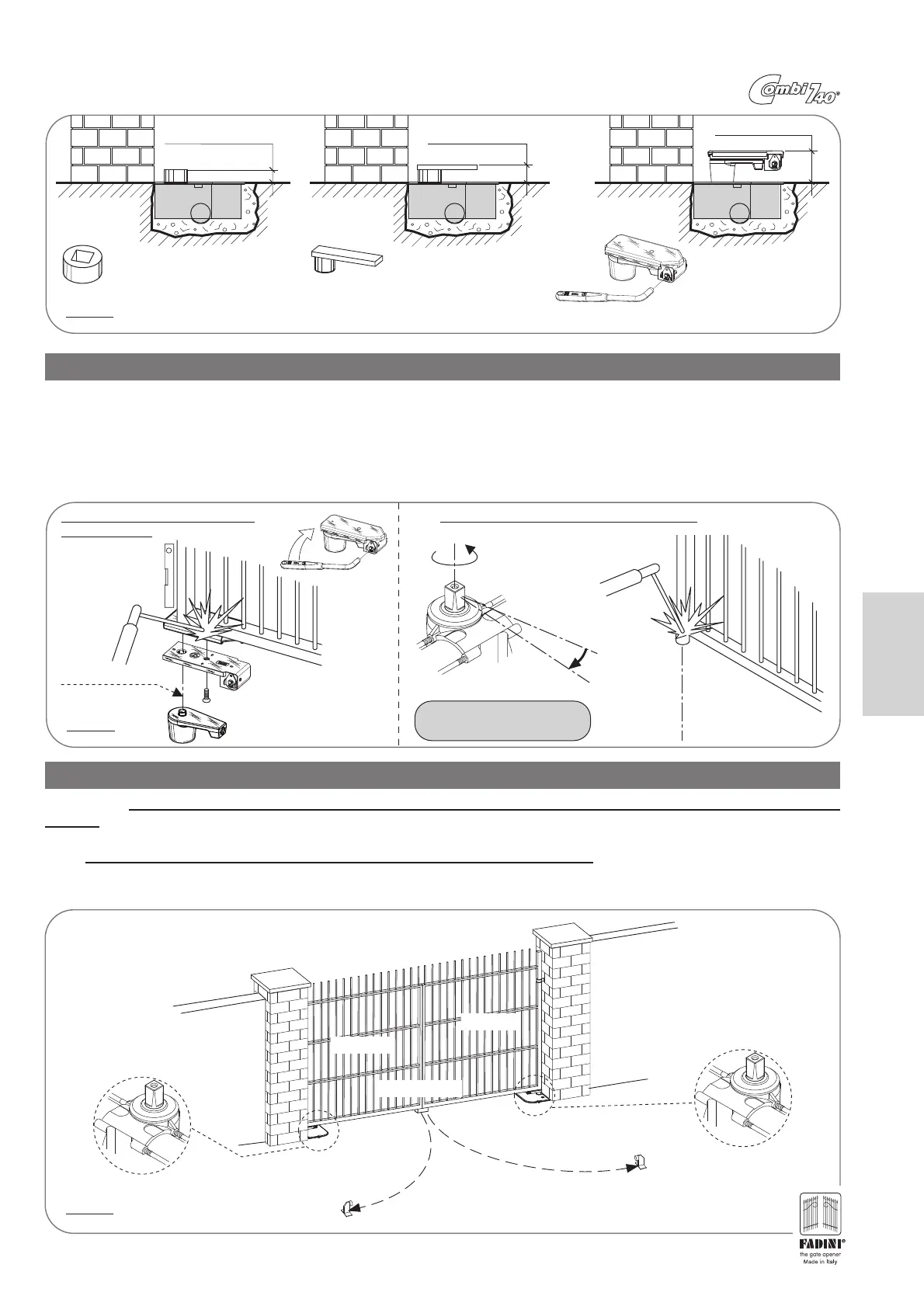

INSTALLING THE RIGHT AND LEFT COMBI 740 INSIDE THE ENCLOSURE

IMPORTANT: The Right and Left Combi 740 are installed respectively to the right and left of the gate, as seen from the inside of the

property: this distinction (version Right and Left) is indicated by the stamp on the base of the square rotation shaft, made during the

manufacturing process at the factory (Pic.15).

NOTE: All what previously described also applies to installations with single leaf swing gates.

IMPORTANT: Before installing and making the electrical connections to the automated devices, the leaf opening and closing stops

must be secured to the ground (Opening leaf stop approx. 5° before the rotation shaft's end of travel).

Sx

Dx

Left gate

Right gate

Right leaf open gate stop

(Not provided by the manufacturer)

Right Combi 740

Left leaf open stop

(Not provided by the manufacturer)

Left Combi 740

The abbreviation “Dx”

indicates the Right Combi 740

The abbreviation “Sx”

indicates the Left Combi 740

Close stop

Shaft rotation

closing

end of travel

Rotate by 5° or 10°, before the rotation

shaft arrives at the end of travel.

PIC. 14

PIC. 15

23

English

IMPORTANT: the single square hole ferrule must be welded to the leaf with the Combi 740 shaft rotated by 5° or 10°, before it arrives

at the end of travel. (Pic.14). (Putting into phase process).

Sx

Welding the manual emergency override

or support bracket

Gate connection: by welding either the ferrule directly

Leaf rotation

axle

Level

Travel end axle

Closed gate axle

PIC. 14

Shaft rotation

closing

end of travel

Leaf rotation

axle

Rotate by 5° or 10°, before the rotation

shaft arrives at the end of travel

Loading...

Loading...