page 13

meccanica

FADINI

GB

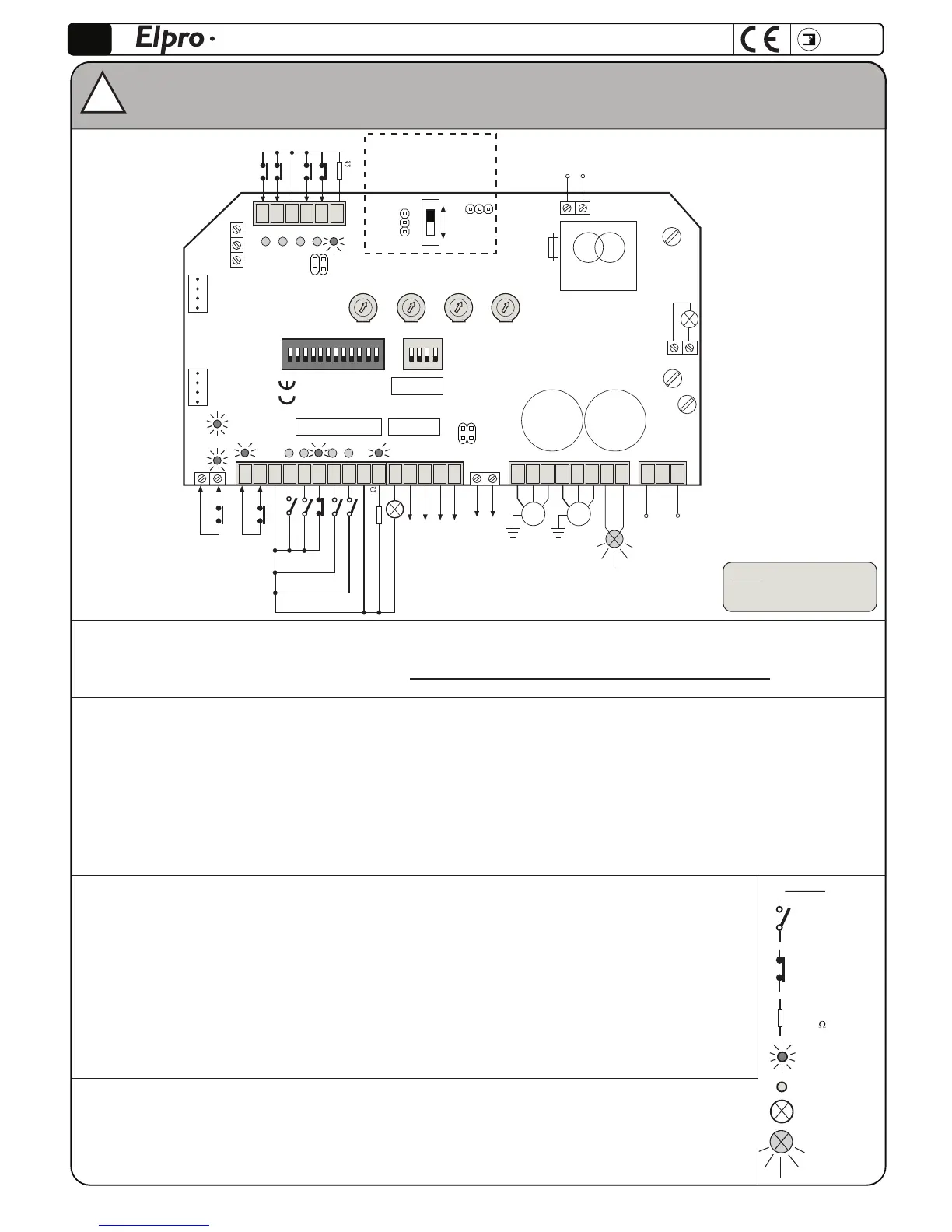

IN CASE OF FAILURE PLEASE MAKE SURE THAT

- Power supply to the electronic control box is 230V ±10%

- Power supply to the electric motor is 230V ±10%

- All of the fuses is all right

- The photocell contacts are closed

- No voltage drop has occurred from the Elpro board to the electric motor

- All of the NC contacts of the control board are all right

IMPORTANT FOR THE INSTALLATION AND THE CORRECT FUNCTIONING:

- The control box must be installed in a dry and sheltered place; suitable holes are provided with the FADINI universal box for fitting purpose and in

case any commercial box is used, this must be adequate to the job

- Make sure that power supply to the control board be 230V ±10%

- Make sure that power supply to the electric motor be 230V ±10%

- For distances longer than 50 metres increase the section of the wires

- Fit the mains to the control box with a high sensitivity, 0.03A, differential, magnetic-thermal circuit breaker

- Cables with 1.5mm² section wires are to be used for the power supply, electric motor and flasher for distances up to 50 m

- Cables with 1mm² section wires are to be used for the limit switches, photocells, push buttons and accessories

- If no photocells are used link out terminals 1 and 2

- If no stop button is used link out terminals 3 and 6

- Open/Close motor run time trimmer must be always superior to the time actually required for the gate travel

N.W.: For applications such as light switching, CCTV, etc. use solid state relays to prevent the microprocessor from being affected

Diagnostic LEDs:

L ON = Board on 230V voltage and F1, F2, F3 fuses all right

L0 ON = 2

nd

pair photocells, not obstructed

L1 ON = 1

st

pair photocells not obstructed

L4 OFF = Open, it switches on by any open pulse

L5 OFF = Close, it switches on by any close pulse

L6 ON = Stop, it switches off by any stop pulse

L7 OFF = Radio, it switches on by any pulse from the transmitter/radio contact

L8 OFF = Pedestrian mode, it switches on by any pedestrian pulsing

L10 ON = Safety edge protecting closing

L30 ON = It switches off when Fc.A. (limit switch Opening = L-sw.O) is engaged, M1

L31 ON = It switches off when Fc.C. (limit switch Closing = L-sw.C) is engaged, M1

L33 ON = It switches off when Fc.A. (limit switch Opening = L-sw.O) is engaged, M2

L34 ON = It switches off when Fc.C. (limit switch Closing = L-sw.C) is engaged, M2

L35 ON = Safety edge protecting opening

ATTENTION: before starting the electrical connections, select the mode of operation depending on gate type

by Dip Switch B N°1 and read the instructions respectively dedicated as follows:

SLIDING gates from page 13 to page 18 - SWINGING gates from page 19 to page 23.

!

Symbols

NC Contact

NO Contact

Led ON

Led OFF

Pilot light

Flasher

27

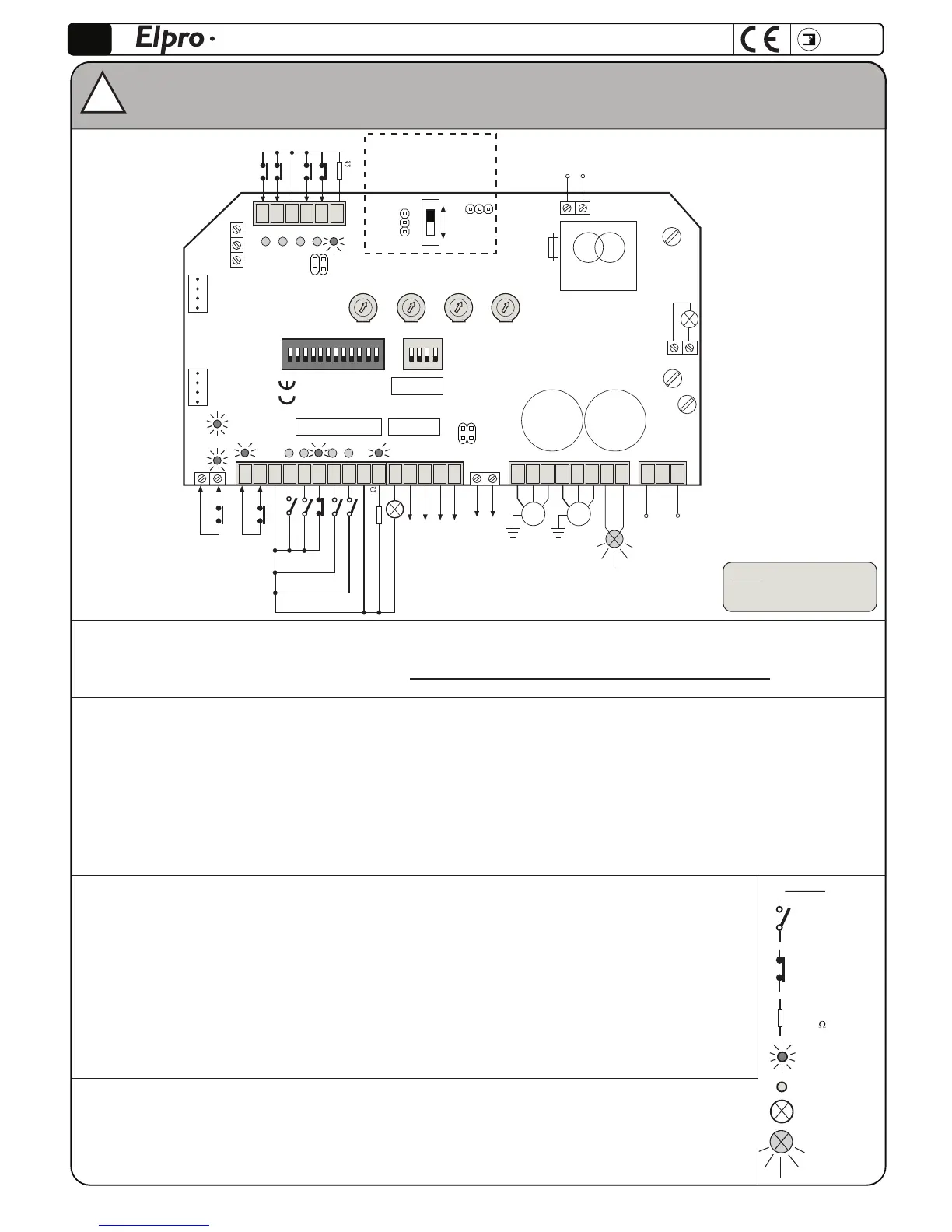

UNIVERSAL ELECTRONIC CONTROL BOX

SINGLE-PHASE 230V 50/60Hz

General description: the electronic control box ELPRO 27 has been developed to provide a reliable unit to control single or double sliding gate automatic

systems with or without limit switches, as well as single or double swinging gate systems fitted with pressure valves. S-phase 230V 50/60Hz ELPRO 27

complies with the Low Voltage Norms 2006/95 CE and Electro-magnetic Compatibility 2004/108/CE. Installation is recommended by qualified technical

installation agents in compliance with the existing regulations. The manufacturer is not liable for any incorrect use of this appliance; and also reserves

the right to change and update it without previous notice.

ELECTRIC MOTORS

230V SINGLE-PHASE

Power supply

350W max (0.5HP)

M1

M2

F3=2A

24V low

voltage circuit

protection

F2=5A

network

F1=5A

network

COURTESY LAMP

230V MAX 100W

It goes on when gate

starts and stays on for

a fixed time of 90

seconds after motor

run time expiry

TRANSFORMER

1 2 3 4 5 6 7 8 9 10 11 1213 14 15 16 17 18 19 20 21 22 23 24 25

PLUG-IN

RADIO

CARD

CONNECTOR

2

nd

pair

photocells

NC

1

st

pair

photocells

radio contact

common

open

close

stop

Indication lamp 24V

max 3W

24Vac output (max. load:

n°1 radio receiver

n°3 pairs photocells)

power supply for

electric lock

15VA max

230Vac OUTPUT

max 25W for flasher

and electric latch

Control board

power supply

230V - 50/60Hz ±10%

24V /ac output

for photocell TX

enabling DSA control

NC

common

common

NEUTRAL

LIVE

26

27

28

CARD

CONNECTOR FOR

TRAFFIC LIGHTS

(Item 7282L)

+

_

Power supply

24V - 50mA max.

DC AC

Selector

DC/AC

3 2 1

12V

24V

3 2 1

Pedestrian opening

LOCK

SETUP

Capacitor

M1 Motor

12.5 µF

Capacitor

M2 Motor

12.5 µF

F4=630mA

Transformer

primary

protection

OUTPUT CONFIGURATION

TERMINALS 14 - 15

UNL

ON

OFF

1 2 3 4 5 6 7 8 9 10 11 12

DIP-SWITCH - A

RUN TIME

OPEN - CLOSE

sliding: 0s - 120s

swinging: 0s - 60s

DWELL

TIME

1s - 220s

- GATE DELAY

CLOSING: 0s - 10s

- OPENING FOR

PEDESTRIANS 1s - 45s

-

+

-

+

-

+

ON

OFF

1 2 3 4

DIP-SWITCH - B

ELPRO 27

UNL

E 27

L4 L5 L6 L7 L8 L10

-

+

ELECTRIC LOCK

TIME

0.5s - 20s

L30 L31 L33 L34

30 31 32 33 34

M1 M2

Fc.A.

Fc.C.

Fc.A.

Fc.C.

35

L35

JA

1

2

SETUP

EDGE

TYPE

safety edge in closing

common

JB

1

2

Safety edge

in Opening

8,2 k

or NC

8,2 k

or NC

Resistive contact

8,2 k or NC

L

L0

L1

NOTE:

The green LEDs must

always be on.

Loading...

Loading...