3

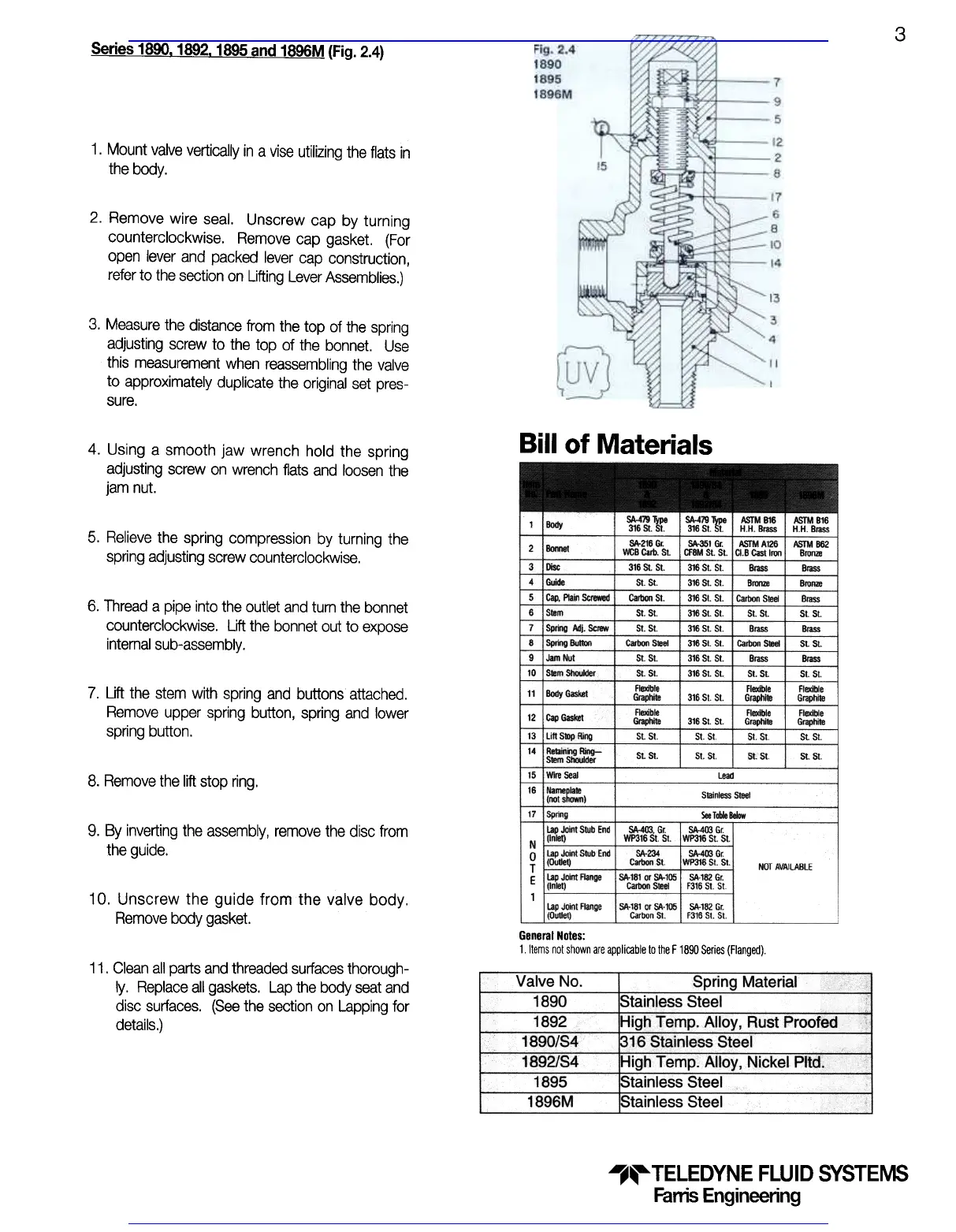

Series 1890. 1892. 1895 and 1896M (Fig. 2.4)

1. Mount valve vertically in a vise utilizing the flats in

the body.

2. Remove wire seal. Unscrew cap by turning

counterclockwise. Remove cap gasket. (For

open lever and packed lever cap construction,

refer to the section on Lifting Lever Assemblies.)

3. Measure the distance from the top of the spring

adjusting screw to the top of the bonnet. Use

this measurement when reassembling the valve

to approximately duplicate the original set pres-

sure.

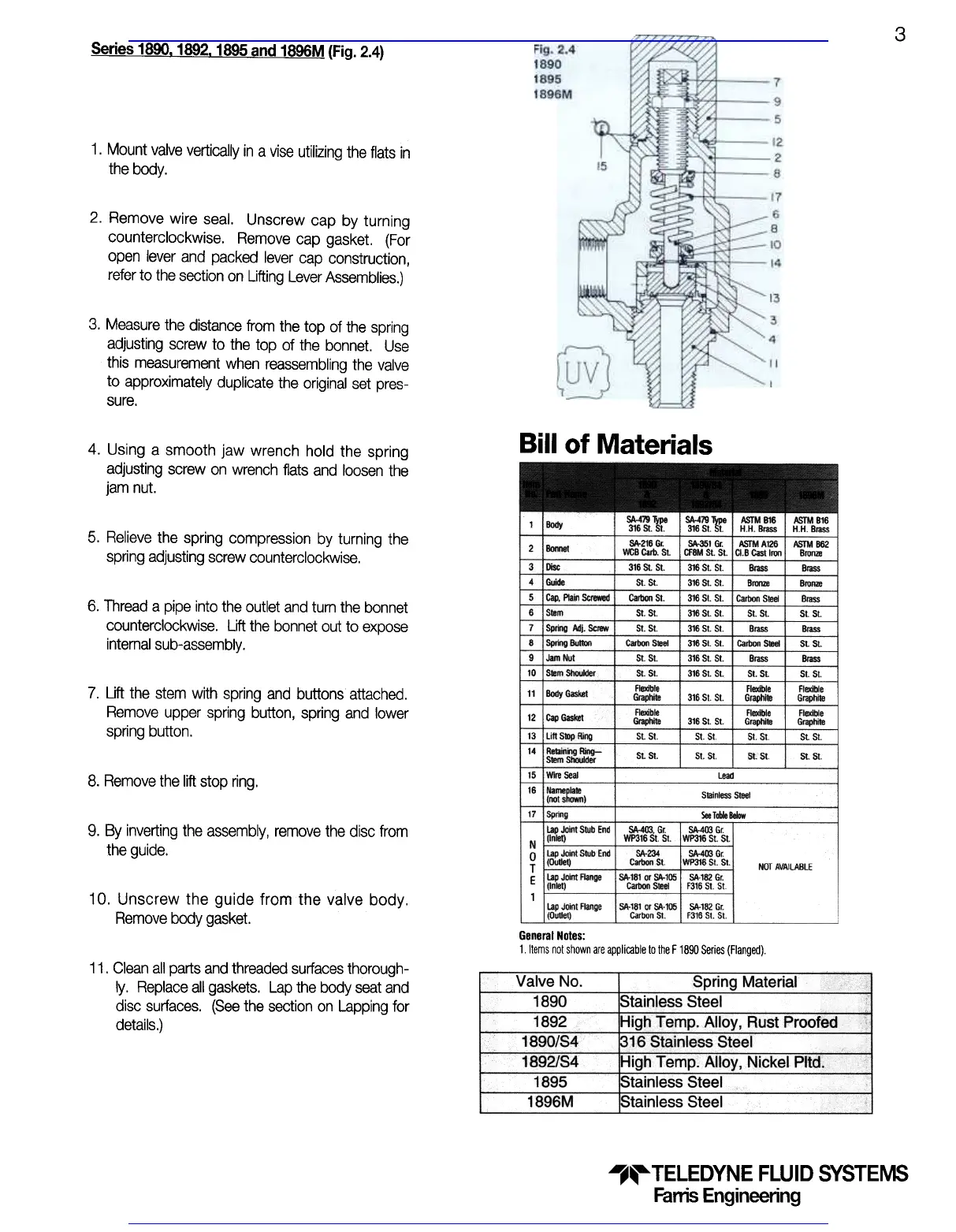

Bill of Materials

4. Using a smooth jaw wrench hold the spring

adjusting screw on wrench flats and loosen the

jam nut.

SA.479 Type I SA-419 Type

316 St. 51 316 51. 51.

5. Relieve the spring compression by turning the

spring adjusting screw counterclockwise.

316 St SI I 316 SI. St

316 SI. St.StSt.

CaIIIon St.

St. St.

St 51

1 I!Orjy

",," ,

2 Bonnet

~~~-, ~~

3 ~ c

4 Glide St St.

5 ~, Plain ~ CaIIIon St.

6 Sf8m St. St.

7 Sprilg Adj. Screw St. St.

8 SpIi1O BIIt1On ..-c

9 Jam Nut St St

10 Smm ShOtJkIer St St

11 Body Gasket =~

12 Cap GasI<et =I:e

13 Lift Slop Ring St St

14 Relainmg Ring- St St

Stem SOOWder .

15 Wire Seal

16 Namepmm

(not shown)

17 Spring

lap Joint Stub End

N (In~)

0 Lap Jamt Stub End ~234

T (OUllet) Carbon St

E Lap JoHrt Range ~181 or ~105

(Inlet) Carbon Steel

1

lap Joint Flange ~181 Qr SA-105

(O.l1et) CarbQrJ St

6. Thread a pipe into the outlet and turn the bonnet

counterclockwise. Lift the bonnet out to expose

intemal sub-assembly.

7. Uft the stem with spring and buttons attached.

Remove upper spring button, spring and lower

spring button.

8. Remove the lift stop ring.

9. By inverting the assembly, remove the disc from

the guide.

~. Gr SA-4O3 Gr

WP316 51 51 WP316 5t St.

SA-403 Gr

WP316 St. St.

SA-182 Gr.

F316 St 5t.

SA-152 Gr.

F316 5t. 5t.

NOT AVAILABLE

10. Unscrew the guide from the valve body.

Remove body gasket.

General Noles:

1 Items not shown are applicable to the F 1890 Series (Flanged).

11. Clean all parts and threaded surfaces thorough-

ly. Replace all gaskets. Lap the body seat and

disc surfaces. (See the section on Lapping for

details.)

Valve No.

1890

1892

1890/84

1892/84

1895

1896M

Spring Material

Stainless

SteelHigh

Temp. Alloy, Rust Proofed

316 Stainless SteelHigh

Temp. Alloy, Nickel Pltd.Stainless

SteelStainless

Steel

TELEDYNE FLUID SYSTEMS

Fanis Engineering

Visit www.boighill.com to request a quote.

Visit www.boighill.com to request a quote.

Loading...

Loading...