MSS

TM

Series

© Copyright 2022 Fluid Equipment Development Company | www.fedco-usa.com

- 34 -

Figure 67 - Discharge Housing Alignment Pin

6. Locate the discharge housing anti-rotation

pin on the bearing carrier and note the loca-

tion of the discharge housing anti-rotation

pin hole.

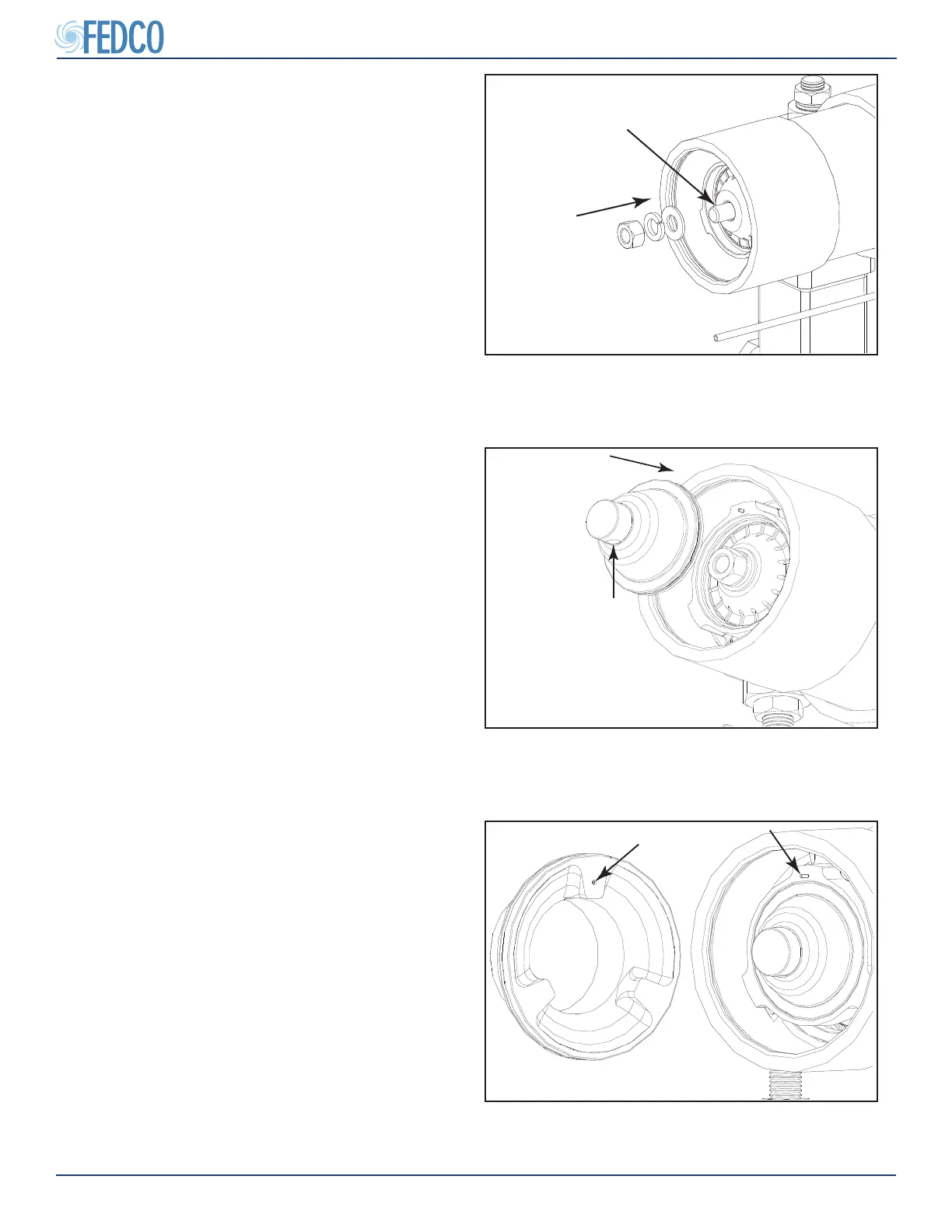

Figure 66 - Installing Cavity Cover

5. Lubricate the cavity cover O-ring and install

the cavity cover.

NOTES: Make sure to align throttle nipple

opening with the bottom of the pump.

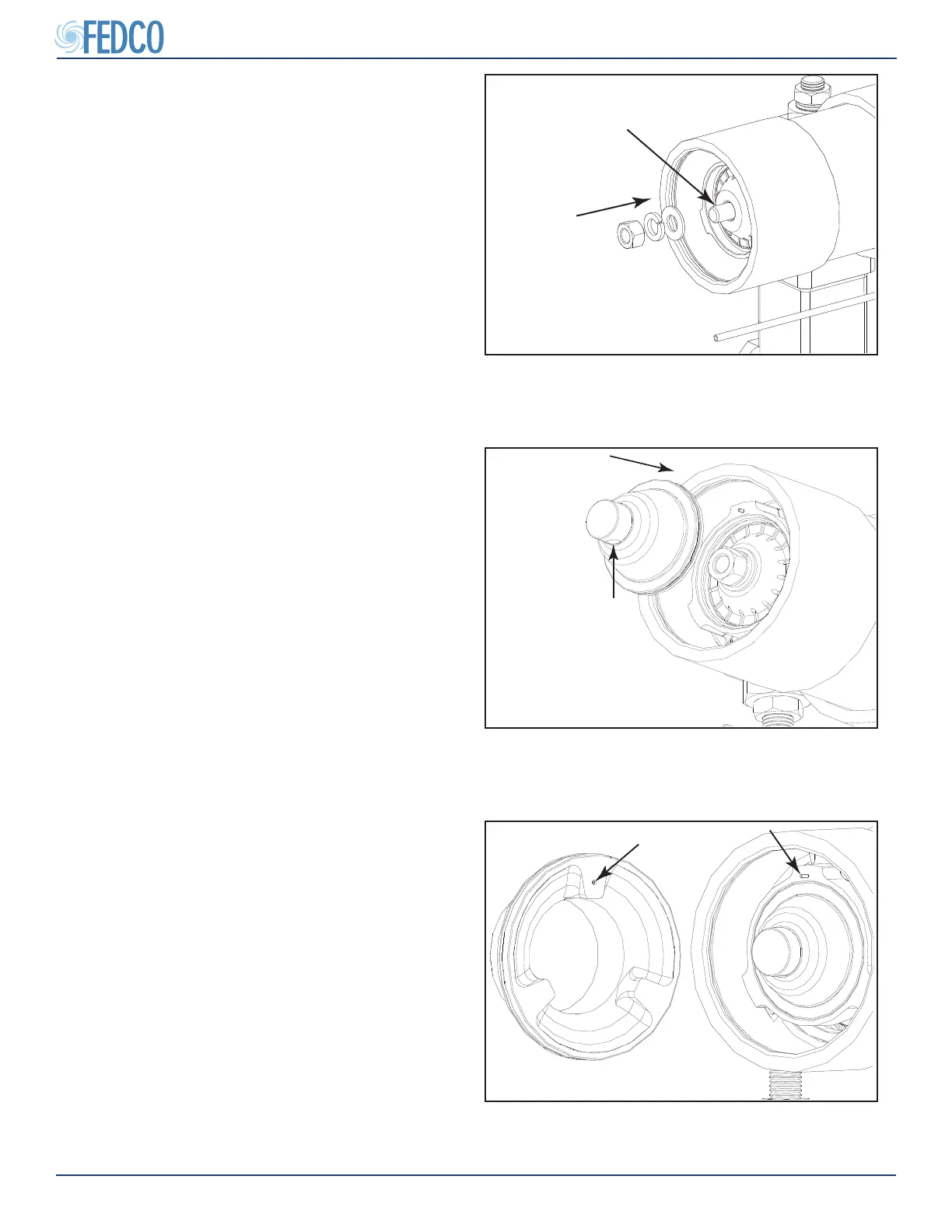

Figure 65 - Installing Balance Disc Washers

and Nut

APPLY SYSTEM COMPLIANT

ANTI-SEIZE COMPOUND

4. Apply system compliant anti-seize com-

pound onto the pump shaft threads and

install the balance disc washer, lock washer

and shaft nut. Tighten to torque value speci-

ed in the Fastener Torque Specications

section of this manual.

NOTES: The pump shaft nut preload is critical

to proper balance disc operation. A properly

calibrated torque wrench must be used for this

step.

Pump Overhaul Continued

Loading...

Loading...