MSS

TM

Series

© Copyright 2022 Fluid Equipment Development Company | www.fedco-usa.com

- 52 -

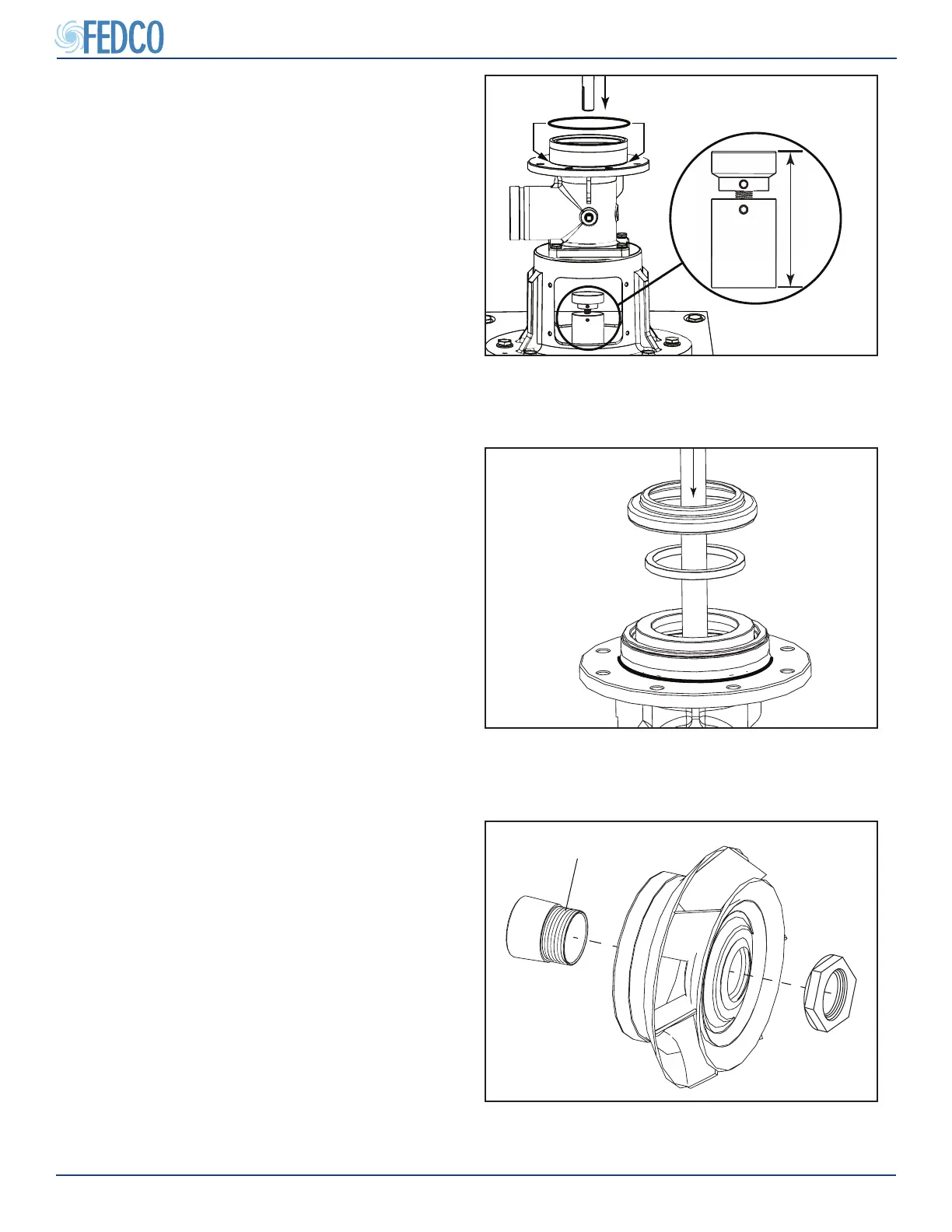

Figure 115 - Impeller Assembly

Anti-Seize

3. Apply anti-seize compound to the split cone

threads

4. Install the split cone into the impeller

5. Loosely install the split cone nut onto the

split cone

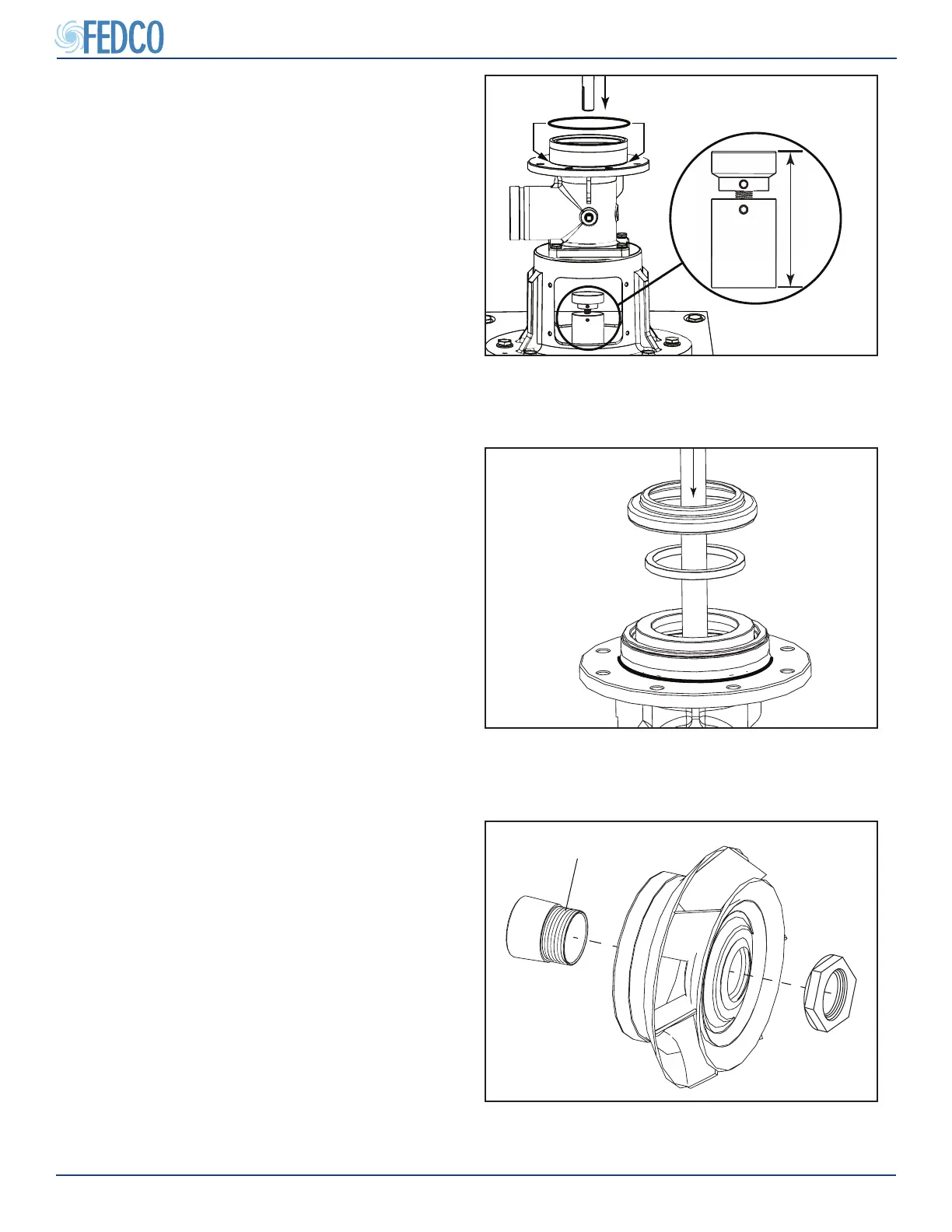

Figure 114 - Floating/ Clamping Neck Ring

Installation

2. Install a oating neck ring and clamping neck

ring from into the inlet ring.

Pump Overhaul Continued

Figure 116 - Shaft Installation

b. Slowly lower the pump shaft into the inlet

until the pump shaft end rests on the gage

block.

6. Lubricate and install the inlet O-ring.

NOTES: Gauge block height should be preset

from the stage removal section. Verify height

before building. Contact FEDCO eld service

for gauge block height if unknown. The pump

serial number must be provided.

Loading...

Loading...