MSS

TM

Series

© Copyright 2022 Fluid Equipment Development Company | www.fedco-usa.com

- 53 -

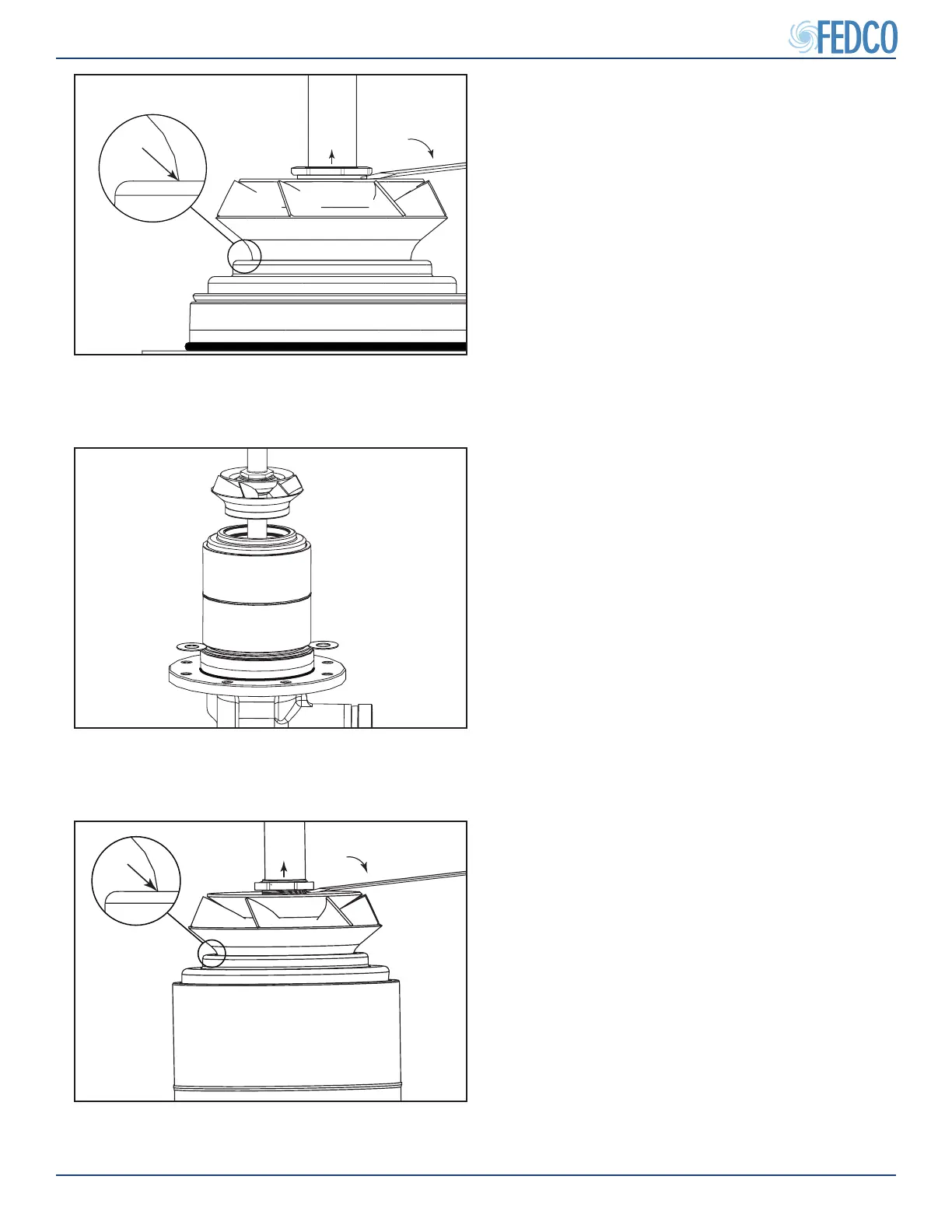

Figure 119 - Impeller Installation

13. Adjust the impeller height so that the seam

on the impeller ring is level with the top of

the oating neck ring.

14. Using a suitable tool, gently pry upwards on

the split cone nut and draw the split cone up

into the impeller before tightening.

15. Grasp impeller to prevent rotation and

tighten split cone nut to torque value speci-

ed in the Fastener Torque Specications

section of this manual.

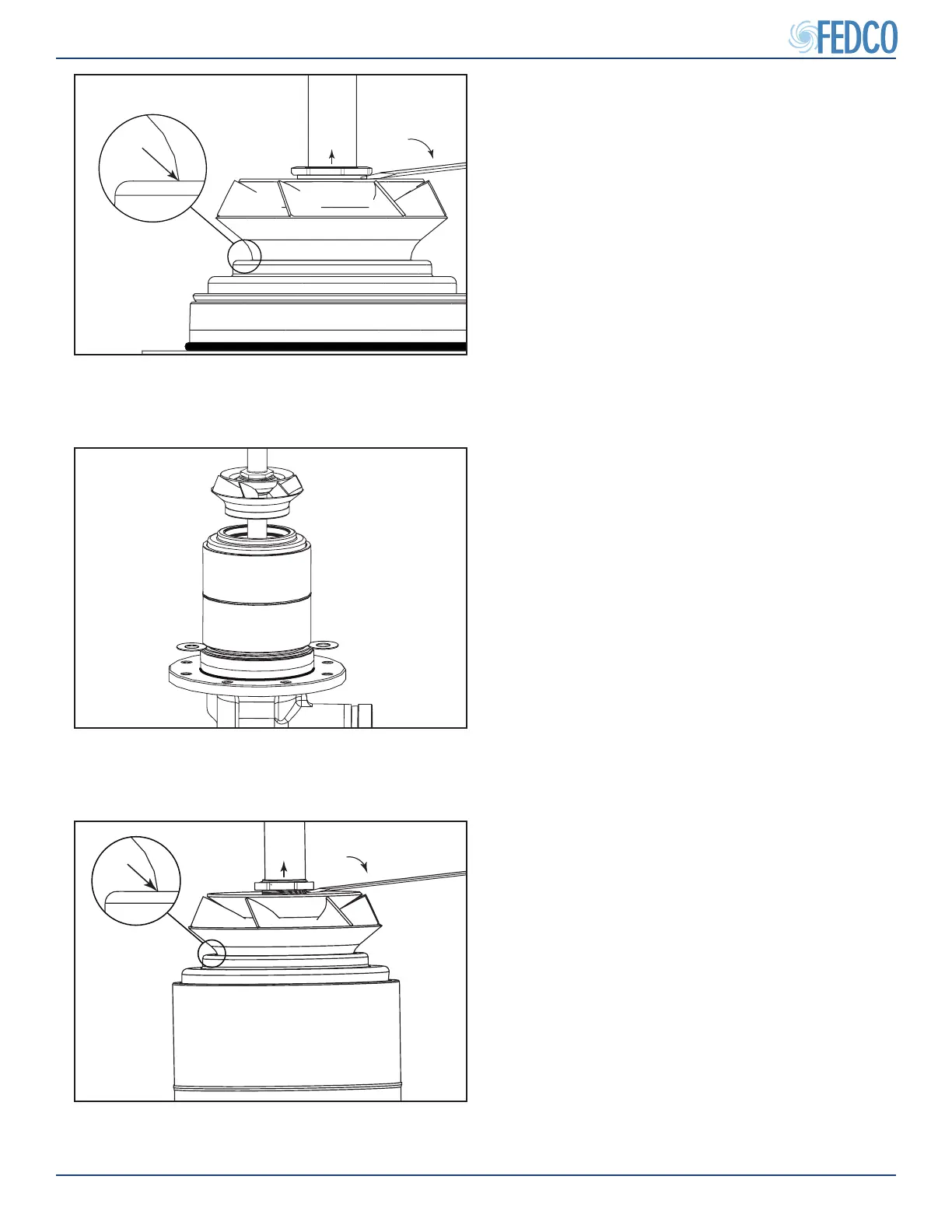

Figure 118 - Diuser Installation

10. Place two (2) spacer washers approximate-

ly 2.8mm (0.11”) thick between the inlet ring

and diuser.

11. Install a fully assembled diuser (diuser,

diuser bearing, oating neck ring, and

clamping neck ring) onto the pump shaft

and seat the diuser assembly onto the

spacer washers.

12. Repeat the impeller assembly procedure

and slide assembly onto pump shaft.

Figure 117 - Impeller Installation

Impeller ring seam and

top of oating neck ring

7. Slide the impeller assembly over the pump

shaft and adjust the impeller height so that

the seam on the impeller ring is level with

the top of the oating neck ring.

8. Using a suitable tool, gently pry upwards on

the split cone nut and draw the split cone up

into the impeller before tightening.

9. Grasp impeller to prevent rotation and tight-

en split cone nut to torque value specied in

the Fastener Torque Specications section

of this manual.

Pump Overhaul Continued

Loading...

Loading...