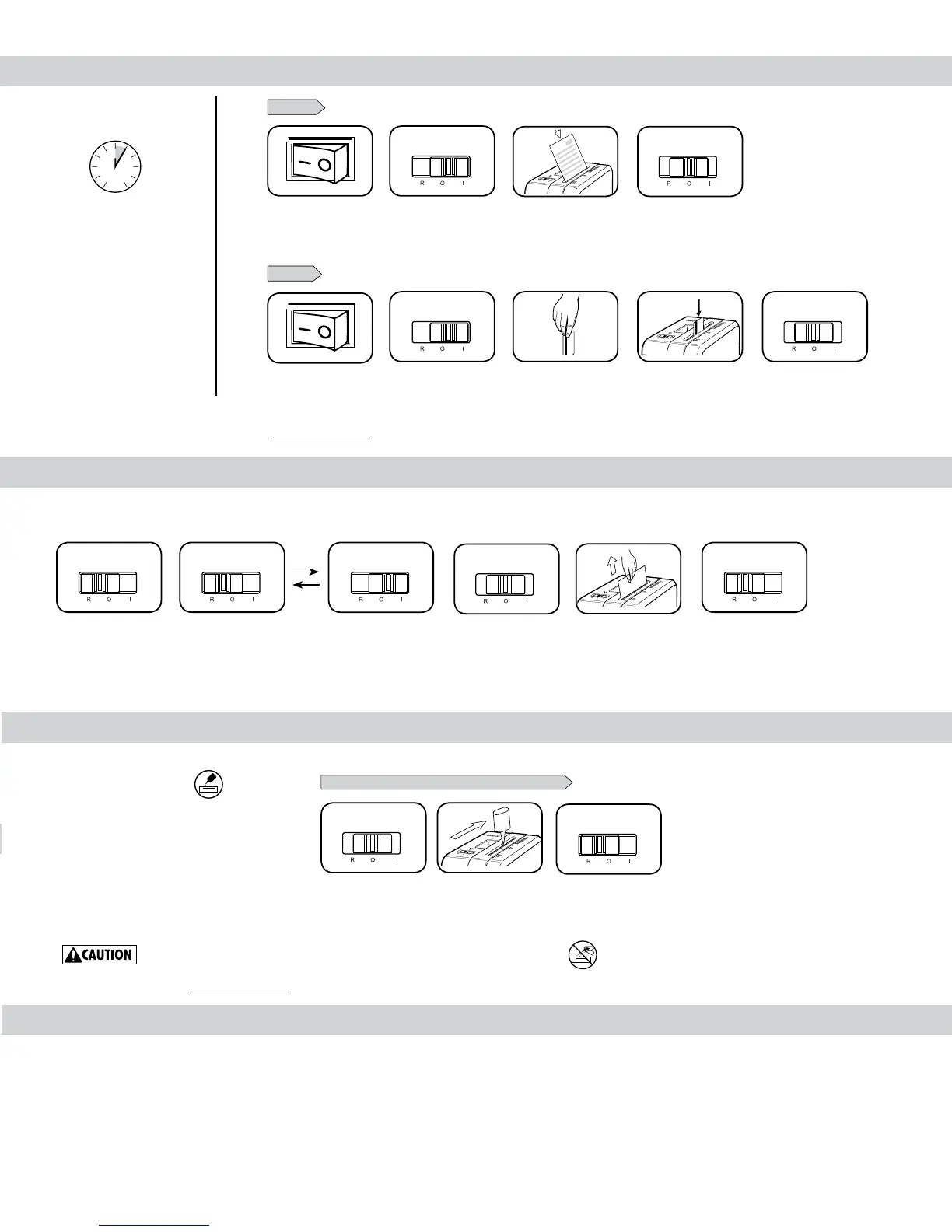

Plug in and put

disconnect power

switchinON(I)position

7

D S

-

7

0 0 C

7

7

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7 0 0 C

D S

-7 0 0 C

7

7

7

7

DS-7 00C

7

D S - 7 0 0 C

7

D S

-7

0 0 C

7

7

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7 0 0 C

D S

-7 0 0 C

7

7

7

7

DS-7 00C

7

D S - 7 0 0 C

7

D S

-7

0 0 C

7

7

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7 0 0 C

D S

-7 0 0 C

7

7

7

7

DS-7 00C

7

D S - 7 0 0 C

7

D S

-

7

0 0 C

7

7

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7 0 0 C

D S

-7 0 0 C

7

7

7

7

DS-7 00C

7

D S -7 0 0 C

7

D S

-7

0 0 C

7

7

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7 0 0 C

D S

-7 0 0 C

7

7

7

7

DS-7 00C

7

D S -7 0 0 C

7

D S

-7

0 0 C

7

7

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7 0 0 C

D S

-7 0 0 C

7

7

7

7

DS-7 00C

7

D S -7 0 0 C

7

D S

-7

0 0 C

7

7

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7 0 0 C

D S

-7 0 0 C

7

7

7

7

DS-7 00C

7

D S -7 0 0 C

7

D S

-7

0 0 C

7

7

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7 0 0 C

D S

-7 0 0 C

7

7

7

7

DS-7 00C

7

D S -7 0 0 C

7

D S

-7

0 0 C

7

7

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7 0 0 C

D S

-7 0 0 C

7

7

7

7

DS-7 00C

7

D S -7 0 0 C

7

D S

-7

0 0 C

7

7

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7 0 0 C

D S

-7 0 0 C

7

7

7

7

DS-7 00C

7

D S -7 0 0 C

7

D S

-7

0 0 C

7

7

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7 0 0 C

D S

-7 0 0 C

7

7

7

7

DS-7 00C

7

D S -7 0 0 C

7

D S

-

7

0 0 C

7

7

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7 0 0 C

D S

-7 0 0 C

7

7

7

7

DS-7 00C

7

D S -7 0 0 C

7

D S

-

7

0 0 C

7

7

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7 0 0 C

D S

-7 0 0 C

7

7

7

7

DS-7 00C

7

D S -7 0 0 C

7

D S

-7

0 0 C

7

7

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7 0 0 C

D S

-7 0 0 C

7

7

7

7

DS-7 00C

7

D S -7 0 0 C

7

D S

-

7

0 0 C

7

7

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7 0 0 C

D S

-7 0 0 C

7

7

7

7

DS-7 00C

7

D S -7 0 0 C

7

D S

-

7

0 0 C

7

7

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7

0 0 C

D S

-

7 0 0 C

D S

-7 0 0 C

7

7

7

7

DS-7 00C

7

D S -7 0 0 C

3

3

TROUBLESHOOTING

BASIC PRODUCT MAINTENANCE

LIMITED PRODUCT WARRANTY

Paper jam: SettoOff(O)andemptybin.Replacebinandfollowanyorallofthebelowprocedures.

Alternate slowly (approx. 2-3 seconds)

betweenReverse(R)andAuto-On(I)

Set to Reverse (R)

for 2-3 seconds

SettoOff(O)

and unplug

Gently pull uncut

paper from paper

entry. Plug in.

Set to Reverse (R)

Feedintopaper

entry and release

Hold card at edge

1

1

2

2

2

3

3

3

4

4

4

5

5

2

6

1

Plug in and put

disconnect power

switchinON(I)position

SettoOff(O)

Feedintocenterof

entry and release

SettoOff(O)

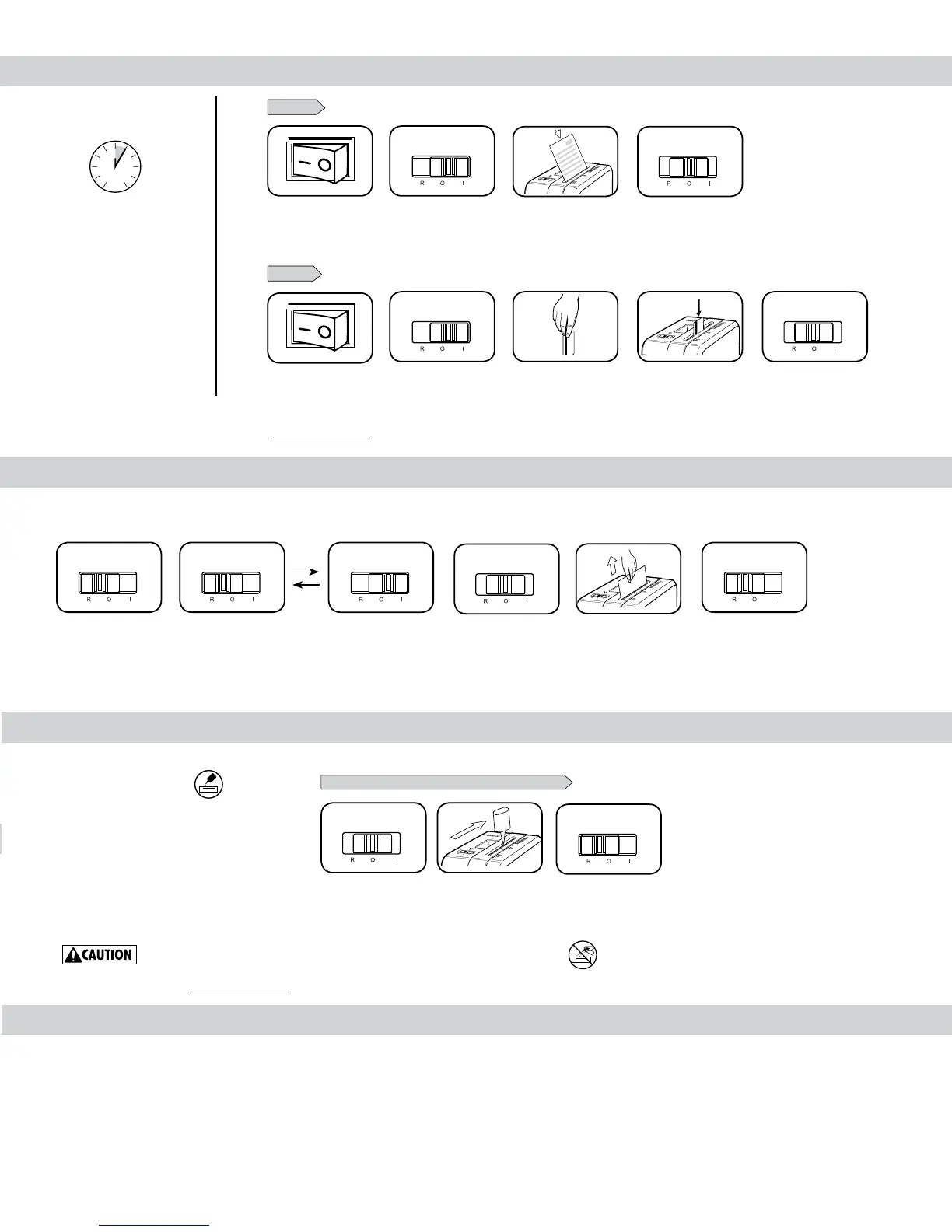

Continuous operation:

5 minute maximum

NOTE: Shredder runs briefly

after each pass to clear entry.

Continuous operation beyond

5 minutes will trigger a

20-minute cool down period.

SettoAuto-On(I)

SettoAuto-On(I)

BASIC SHREDDING OPERATION

LIMITED WARRANTY Fellowes, Inc. (“Fellowes”) warrants the cutting bladesof the machine to

be free from defects in material and workmanship for 3 years from the date of purchase by the

originalconsumer.Felloweswarrantsallotherpartsofthemachinetobefreeofdefectsinmaterial

and workmanship for 1 year from the date of purchase by the original consumer. If any part is

found to be defective during the warranty period, your sole and exclusive remedy will be repair or

replacement,atFellowes’optionandexpense,ofthedefectivepart.Thiswarrantydoesnotapply

incasesofabuse,mishandling,orunauthorizedrepair.ANYIMPLIEDWARRANTY,INCLUDINGTHAT

OFMERCHANTABILITYORFITNESSFORAPARTICULARPURPOSE,ISHEREBYLIMITEDINDURATION

TOTHEAPPROPRIATEWARRANTYPERIODSETFORTHABOVE.InnoeventshallFellowesbeliablefor

anyconsequentialorincidentaldamagesattributabletothisproduct.Thiswarrantygivesyouspecific

legalrights.Theduration,terms,andconditionsofthiswarrantyarevalidworldwide,exceptwhere

differentlimitations,restrictions,orconditionsmayberequiredbylocallaw.Formoredetailsorto

obtain service under this warranty, please contact us or your dealer.

*Only use a non-aerosol vegetable oil in long nozzle container such as Fellowes 35250

Allcross-cutshreddersrequireoilforpeak

performance. If not oiled, a machine may

experience diminished sheet capacity, intrusive

noise when shredding and could ultimately

stoprunning.Toavoidtheseproblems,we

recommend you oil your shredder each time

you empty your waste bin.

OILING SHREDDER

FOLLOW OILING PROCEDURE BELOW AND REPEAT TWICE

* Apply oil

across entry

SettoOff(O)

PAPER

CARD

Set to Reverse (R)

2-3 seconds

www.fellowes.com features an extensive on-line support section with a number of self-service options

Go to Support Section at www.fellowes.com or see back page of manual for useful telephone numbers.

1

1

Loading...

Loading...