16

(1

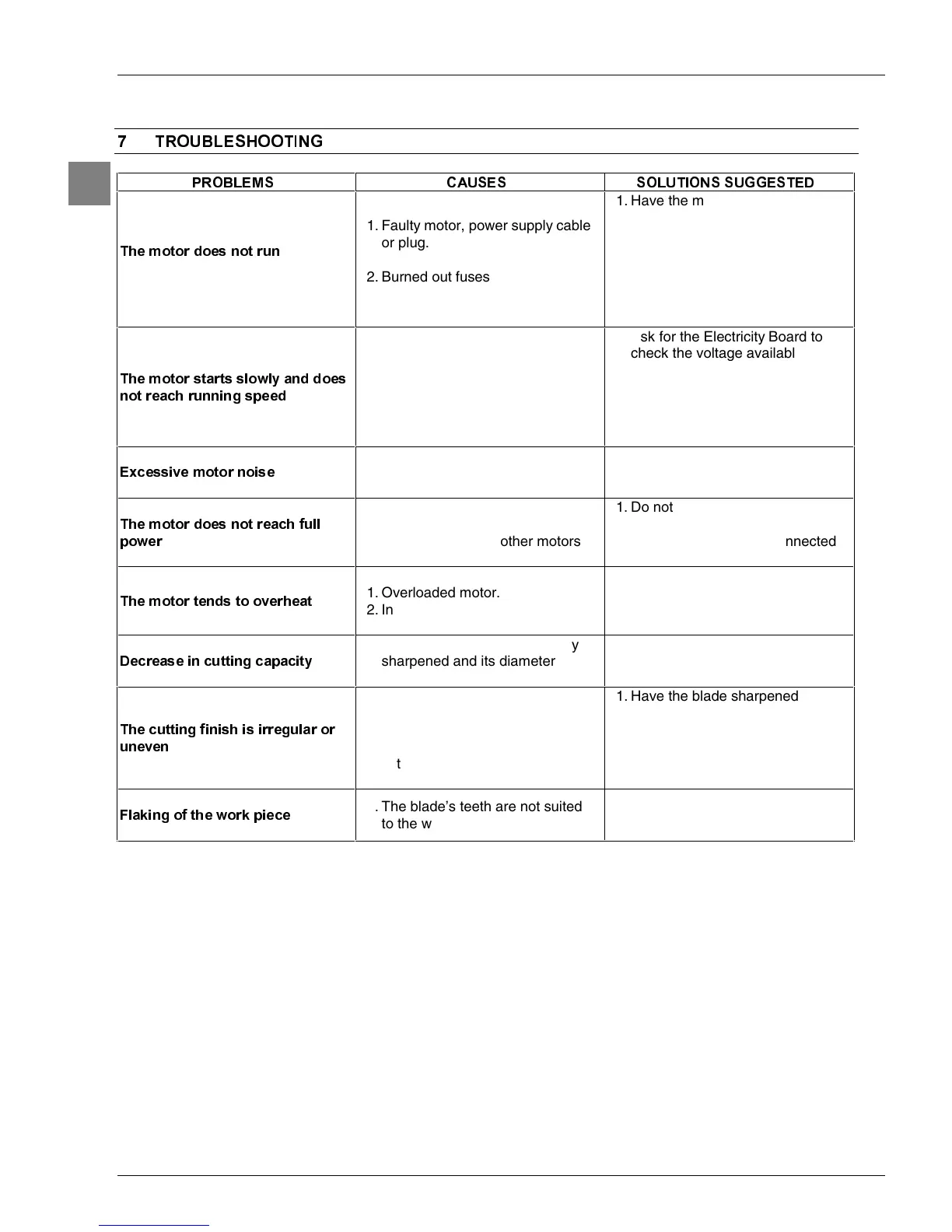

7528%/(6+227,1*

352%/(06 &$86(6 62/87,21668**(67('

7KHPRWRUGRHVQRWUXQ

1. Faulty motor, power supply cable

or plug.

2. Burned out fuses

1. Have the machine checked by

skilled personnel.

Do not try to repair the machine

yourselves as it may be

dangerous.

2. Check the fuses and replace

them if necessary.

7KHPRWRUVWDUWVVORZO\DQGGRHV

QRWUHDFKUXQQLQJVSHHG

1. Low power supply voltage.

2. Damaged windings.

3. Burned out capacitor

1. Ask for the Electricity Board to

check the voltage available.

2. Have the machine motor

checked by skilled personnel.

3. Have the capacitor replaced by

skilled personnel.

([FHVVLYHPRWRUQRLVH

1. Damaged windings.

Faulty motor

1. Have the motor checked by

skilled personnel

7KHPRWRUGRHVQRWUHDFKIXOO

SRZHU

1. Overloaded circuit due to

lighting, utilities or other motors

1. Do not use other utilities or

motors on the circuit to which the

cutting-off machine is connected

7KHPRWRUWHQGVWRRYHUKHDW

1. Overloaded motor.

2. Insufficient motor cooling

1. Avoid overloading the motor

during cutting.

2. Remove dust from the motor in

order to allow adequate cooling.

'HFUHDVHLQFXWWLQJFDSDFLW\

1. The blade has been repeatedly

sharpened and its diameter has

decreased

1. Adjust the limit switch for the

lowering of the head.

7KHFXWWLQJILQLVKLVLUUHJXODURU

XQHYHQ

1. The blade is worn out or the

teeth are not suited to the

thickness of the material being

cut

1. Have the blade sharpened by

skilled personnel.

2. Check that the blade being used

is appropriate by referring to the

paragraph ‘SELECTION OF THE

BLADE’.

)ODNLQJRIWKHZRUNSLHFH

1. The blade’s teeth are not suited

to the work piece

1. Check the appropriate teeth to

use by referring to the paragraph

‘SELECTION OF THE BLADE’

Loading...

Loading...