Installation and Maintenance Manual form 185

Page 15

7.0 REPAIR

For a unit in warranty, attempt no repairs without first

contacting the manufacturer, otherwise your warranty will

be void.

For a unit out of warranty, if the unit is accidentally damaged

while in use, you can make minor shipyard repairs as follows:

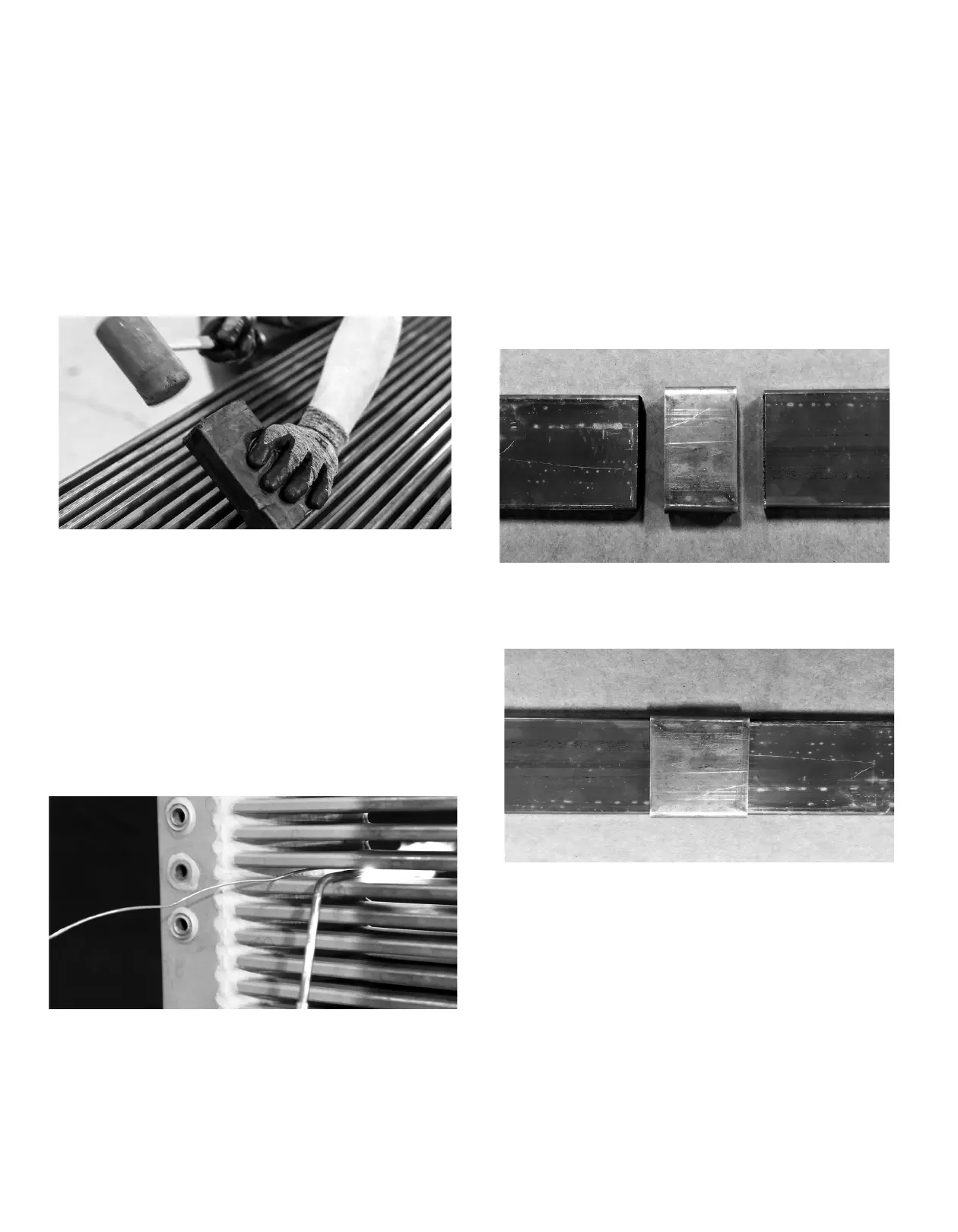

STRAIGHTENING

If the tubes are accidentally bent, they can be straightened

with a hard wood block and a mallet. See Figure 24.

FIG.24 Straightening tubes with a wooden block &

mallet

COPPER-NICKEL GRIDCOOLER® KEEL COOLER

REPAIRS

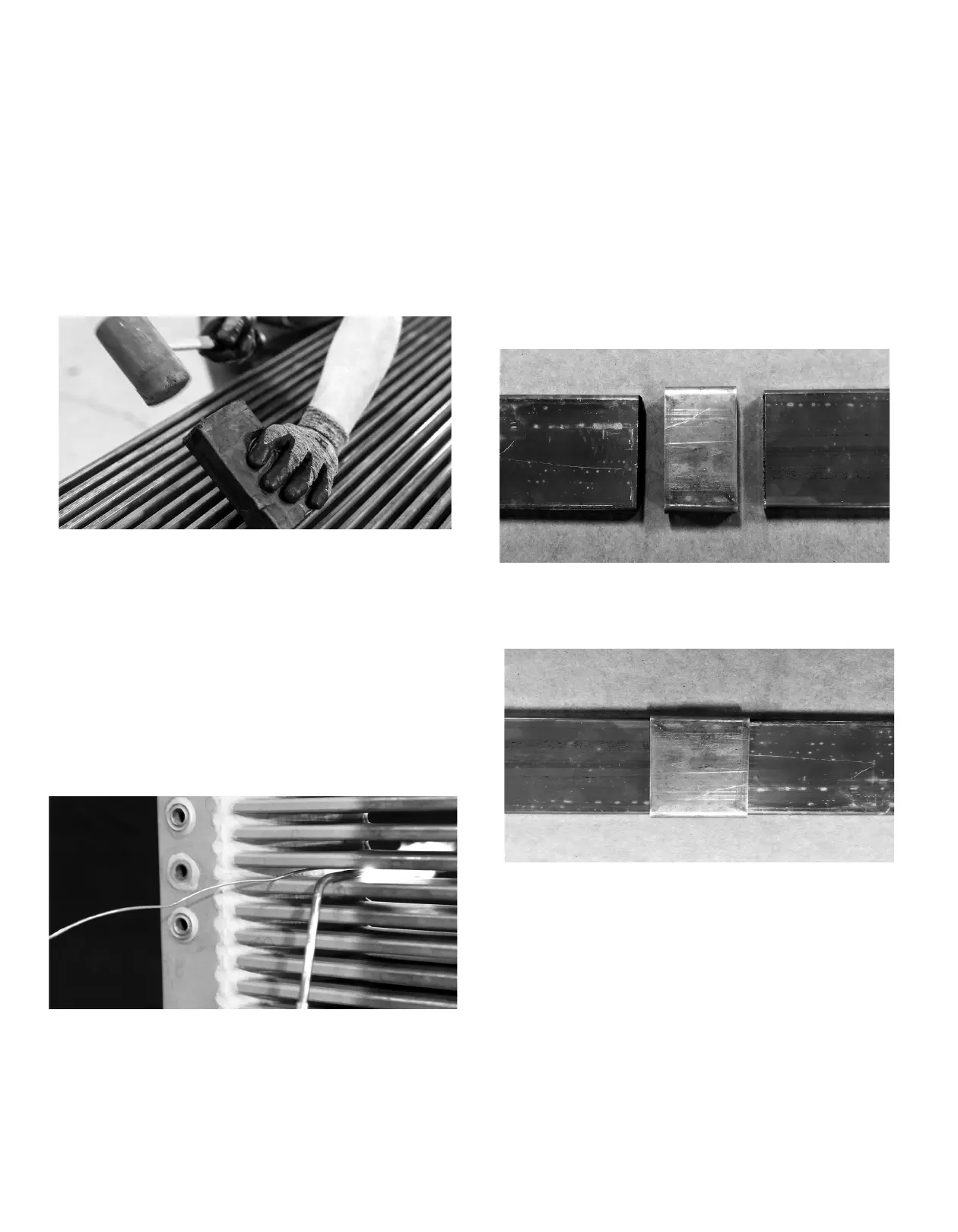

BRAZING:

Drain the cooler before brazing. Clean the area or joint to be

brazed thoroughly with a good degreasing solvent followed

by wire brushing. The braze wire should be 56% silver, AWS

A5.8 BAg-7. See Figure 25.

FIG.25 Brazing repair

TIG WELDING:

C70600 copper-nickel or monel 67 wire may be used.

TEMPORARY REPAIR

For temporary repairs, liberally apply an epoxy compound.

Before applying the epoxy compound, clean the surface of

the GRIDCOOLER unit and relieve any internal pressure.

For major repairs not covered by our Limited Warranty,

contact us. Give us a complete description of the damage,

and we will tell you if and how your unit can be repaired.

TUBE COUPLING REPAIRS

A damaged section of D or C tube can be replaced with two

couplings and a replacement length of tube brazed in place.

FIG.26 Replacing a section of tube

A single coupling can be cut or split, slid over the tube, and

brazed into place to patch a hole in a tube.

FIG.27 Patching a hole in a tube

ALUMINUM GRIDCOOLER KEEL COOLER REPAIRS

TIG WELDING:

Drain the cooler before welding. Clean the area or joint to be

welded thoroughly with a good degreasing solvent followed

by stainless steel wire brushing. The aluminum filler rod used

in the GRIDCOOLER Keel Cooler is R 5554 aluminum wire.

Loading...

Loading...