Page 6

Installation and Maintenance Manual form 185

2.3.2 To avoid over-tightening any of the supporting nuts,

we recommend the following torques for all standard

installations:

2.3.3 Anodes are standard equipment with copper-nickel

units. They minimize the eects of galvanic corrosion

and should be replaced when deteriorated. The life

of these plates varies with localities.

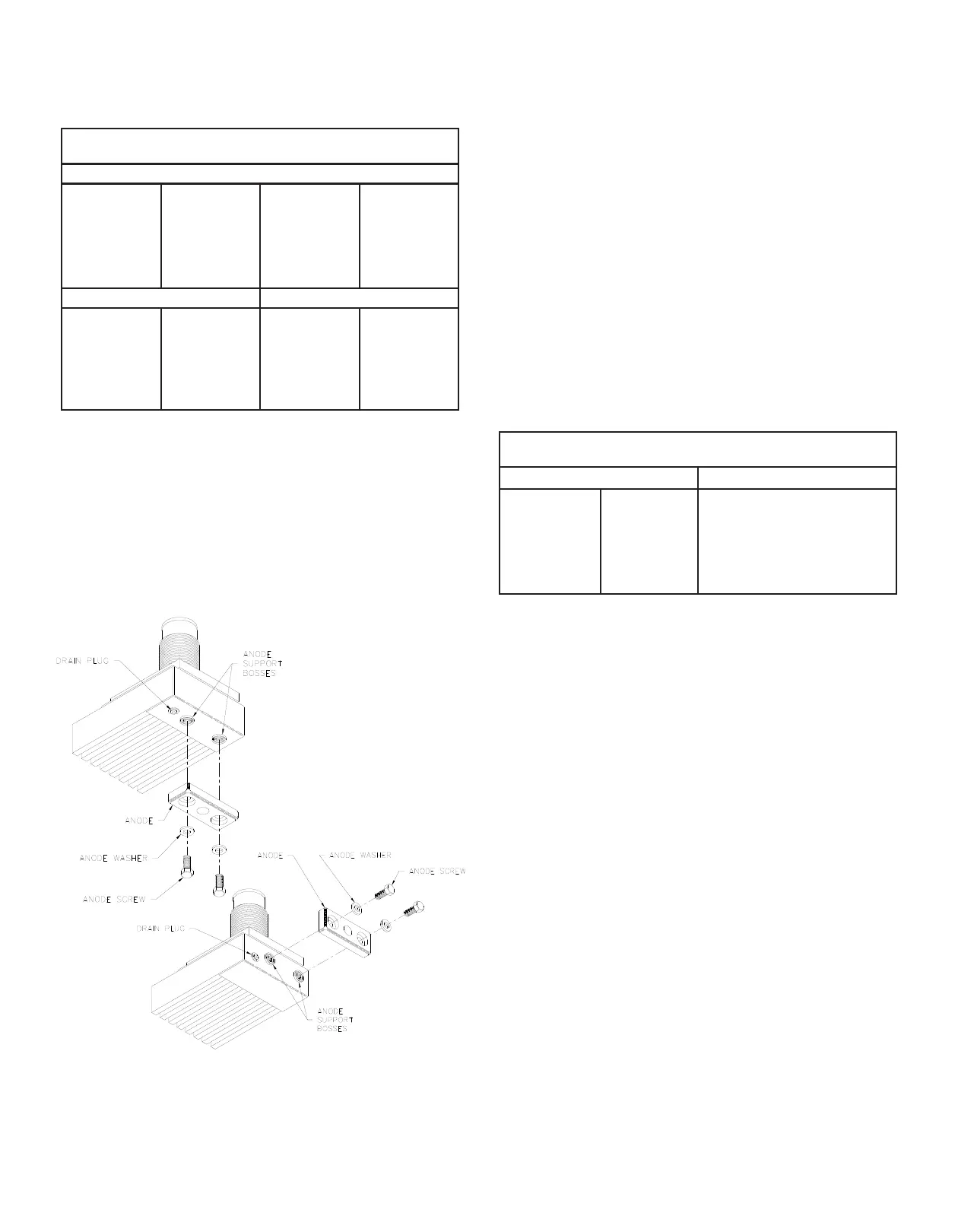

2.3.4 Attach the anodes using the special bolts and

washers supplied with the unit. They can be found

in a cardboard box inside the unit shipping box. See

Figure 10.

FIG.10 Anode Attachment Detail

NOTE: Anode replacement kits, including anodes,

screws, and washers, can be ordered from

the factory. They are available with zinc

anodes or aluminum anodes upon request.

Please provide the model number of your

GRIDCOOLER® Keel Cooler to ensure the

proper replacement anodes are sent.

2.4 ALUMINUM INSTALLATIONS

2.4.1 Aluminum GRIDCOOLER Keel Coolers should be

installed on unpainted aluminum hulls only.

2.4.2 The 1/4-inch mounting gaskets supplied with the unit

must be used to provide proper spacing between

the cooler and the ship’s hull.

2.4.3 To avoid over-tightening any of the supporting nuts,

we recommend the following torques for all normal

installations:

2.4.4 Most aluminum units have tapered threads on the

nipples and no hose connectors (see installation

drawing). These units can be piped directly to the

engine, provided flexible couplings are used to

remove engine vibration between the engine and

the cooler.

2.4.5 If a wire reinforced rubber hose is used to connect

the unit to the engine, put a screw-on coupling over

the cooler nozzle threads.

2.4.6 Aluminum GRIDCOOLER Keel Coolers do not use

anodes.

2.5 PLUMBING

NOTE: Prior to installing cooler, flush entire piping

system to remove any debris.

2.5.1 Remove the orange nozzle plugs from the

GRIDCOOLER unit before hooking up the plumbing

to the cooler.

2.5.2 Engines equipped with inboard raw water heat

exchangers may not be able to be converted to

keel cooling, please consult your engine dealer and

Fernstrum representative for guidance.

2.5.3 As a rule-of-thumb, the expansion tank for your

cooling system should be able to hold approximately

COPPER-NICKEL UNIT

NUT TORQUES FT.-LBS. (KG-M)

NOZZLE THREAD SIZE

¾”

19mm

50 - 60

(7 - 8)

HEADER STUD

SUPPORT BOLT

1 - 1 ½”

25 - 38mm

75 - 100

(10 - 14)

2”

51 mm

125 - 150

(17 - 21)

2 ½ - 3 ½”

63 - 89mm

200 - 250

(28 - 35)

⅝ - ¾”

16 - 19mm

35 - 40

(5 - 5 ½)

1”

25 mm

50 - 60

(7 - 8)

½ - ¾”

13 - 19mm

20 - 25

(3 - 3 ½)

ALUMINUM UNIT

NUT TORQUES FT-LBS (KG-M)

NOZZLE THREAD

1 ½ - 3”

38 - 76mm

125 - 150

(17 - 21)

⅝”

16mm

20 - 25

(3 - 3 ½)

1”

25 mm

75 - 100

(10 - 14)

SUPPORT BOLT

Loading...

Loading...