Installation and Maintenance Manual form 185

Page 5

2.0 INSTALLATION

Once you have decided on the correct location, use

the following steps as a guideline for installing your

GRIDCOOLER® Keel Cooler.

2.1 MAKING HOLES

2.1.1 Measure the distance between the inlet & outlet

nozzles from center to center (also measure to the

centers of the support studs when applicable) before

cutting holes for them in the ship’s hull.

2.1.2 Make the holes through the hull 1/4 in. (6.4 mm)

diameter oversized.

2.1.3 Make sure that the hull surfaces where the unit will

be mounted are smooth and properly aligned (on

steel hulls, if you burn the holes, grind the edges

smooth afterwards). This will allow the gaskets to

seal properly and ensure that no undue stress will be

placed on the cooler.

2.2 FITTING UP

2.2.1 Under normal conditions, the compression of the

mounting gaskets puts sucient tension on the

nozzle nuts (and support bolt nuts when applicable)

to prevent them from working loose. To seal out

water, apply a bead of sealant to the exterior of the

gaskets, and around the points where the nozzles

and support bolts penetrate the hull before assembly.

2.2.2 Remember to tighten the nuts again, after the

caulking has set.

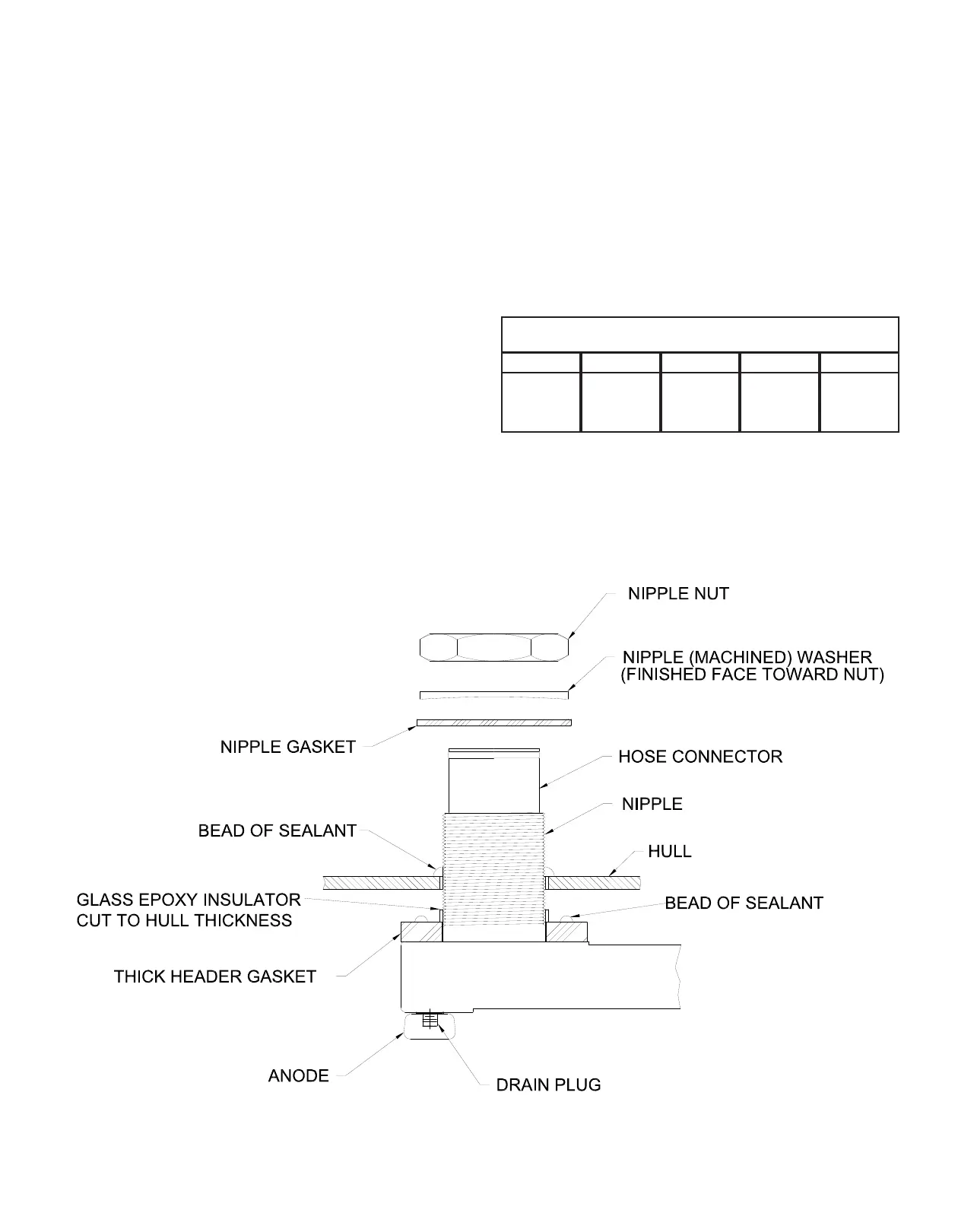

2.3 COPPER-NICKEL INSTALLATION

2.3.1 Mounting gaskets supplied with the GRIDCOOLER

Keel Cooler must be used to provide proper spacing

between the unit and the ship’s hull. See Figure 9.

For exterior gasket thickness see the chart below, all

exterior gaskets are available in ¼” on request

NOTE: INSULATORS: Insulators for galvanic isolation

of through-hull installation studs and nozzles

are available upon request at time of purchase.

When requesting the insulators, provide hull

thickness so the insulators can be supplied at

the proper length.

FIG.9 Mounting Parts Placement

NOTE: IF CONCAVE WASHERS ARE

USED, MAKE SURE CONCAVE SIDE

IS DOWN ON GASKET. FOR NIPPLE

WASHERS THAT ARE CAST, PLACE THE

ROUGH SIDE AGAINST THE GASKET.

EXTERIOR GASKET THICKNESS

B

¼”

6.4mm

½”

12.7mm

¼”

6.4mm

½”

12.7mm

BN

C CN

D

¾”

19mm

Loading...

Loading...