33

The maximum air pressure for cleaning purposes must be

below 205 kPa (30 psi). The maximum water pressure for

cleaning purposes must be below 275 kPa (40 psi).

Engine Maintenance

For engine maintenance schedules and procedures, please

refer to the engine operator's manual.

Containing Spilled Fluids and Proper

Disposal of Waste

Make sure that fluids are contained when performing

inspection, maintenance, testing, adjustment, and repair

of the unit. Be prepared to collect the fluid with suitable

leakproof containers before opening or disassembling any

component containing fluids. Do not pour waste onto the

ground, down a drain, or into any source of water.

Improper disposal of waste can threaten the environment.

Dispose of all fluids according to local regulations and

mandates.

Electronic Fuel Injection (EFI) System -

EFI Models

EFI is an electronically-controlled fuel management system

which is monitored by an Electronic Control Unit (ECU). A

Malfunction Indicator Lamp (M.I.L.) will illuminate if problems

or faults are detected. Servicing by an authorized dealer is

necessary.

CAUTION

Do not disconnect or reconnect ECU wiring harness

connector or any individual components with the ignition

switch in the "ON" position. This can send a damaging

voltage spike through the ECU.

Unplug harness from ECU before performing any welding

on equipment.

Inspect Muffler and Spark Arrester

Inspect the muffler for cracks, corrosion, or other damage.

Remove the spark arrester, if equipped, and inspect

for damage or carbon blockage. If replacement parts

are required, make sure to use only original equipment

replacement parts.

WARNING

Replacement parts must be the same and installed in the

same position as the original parts or fire could result.

Fuse Location and Identification

The electrical system for this unit is equipped with two

replaceable fuses. See the chart below for the circuit,

amperage, and approximate location of the fuses.

Circuit Amperage Approximate

Location

Main 25 amp Instrument control

panel.

PTO Clutch 15 amp Behind the seat on

the left hand side

of the unit.

Some models are equipped with a Starter Relay Jumper

Harness that features 15 amp inline fuse that is locatednear

the battery of the unit.The following units features this

second 15 amp fuse:

• Models with Briggs & Stratton 61G877 engine in serial

number range 4002218815 and above: 5901872,

5901881, 5902039, 5902064, 5902068 & 5902118

• Models with Briggs & Stratton 613777 engine in serial

number range4002180241 and above: 5901937,

5901938, 5902034, 5902035 & 5902067

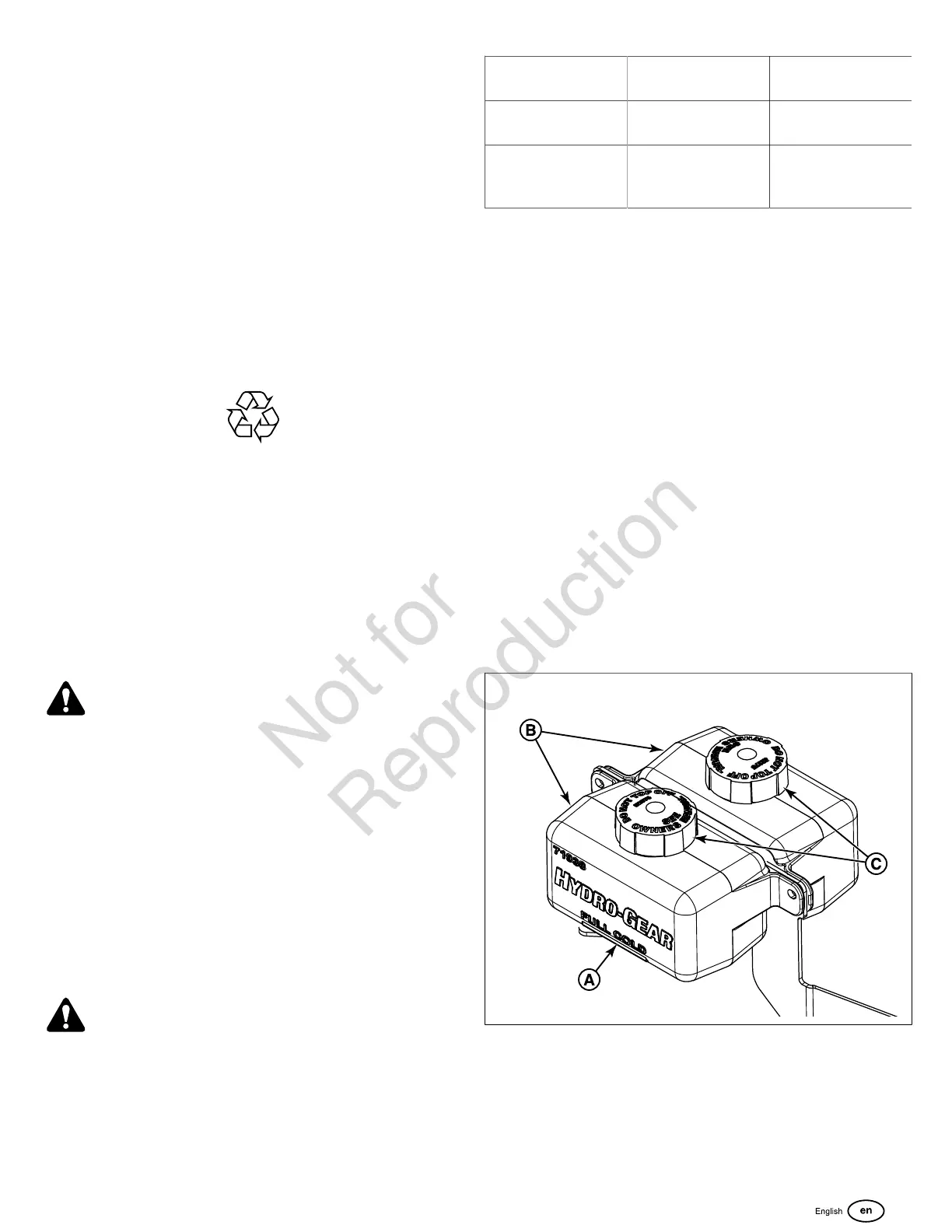

Check / Fill Transmission Oil Level

This unit is equipped with two transmission oil tanks. One

transmission oil tank only supplies oil to one transmission.

The level of oil in both transmission tanks must be checked,

and if necessary, filled.

Oil Type: SAE 20W-50 motor oil

1. Locate the transmission oil tanks (B, Figure 34) by raising

the seat plate of the unit.

2. Check the oil level when the unit is cold. The oil should be

up to the "FULL COLD" mark (A) on the transmission oil

tanks (B). If the oil is below this level, proceed to step #3.

34

3. Before removing the tank cap (C), make sure that the

area around the tank cap and fill neck of the tank is free

of dust, dirt, and other debris. Remove the tank caps.

4. Add oil up to the "FULL COLD" mark.

5. Re-install the tank cap.

6. After adding oil to the tanks, it may be necessary to purge

air from the hydraulic system. If the unit is not driving

Loading...

Loading...