BLUEHELIX TECH RRT 28 C

34 EN

cod. 354M1070 - Rev. 01 - 07/2018

Annual Boiler Service

To ensure the safe operation of the unit over time, a qualified Gas Safe registered engineer must carry out a yearly

inspection, and complete the following checks:

• The control and safety devices (gas valve, flow meter, thermostats, etc.) must operate correctly.

• The flue exhaust duct must be sealed.

• The boiler casing or chamber must be room sealed.

• The Flue terminal and ducts must be free of obstructions, leaks & located correctly to BS5440.

• The burner and exchanger must be clean and free of deposits. Use suitable soft brushes for cleaning. Never use

chemical products. (Wash down through the exchanger & out through the condense line with clean warm water).

• The electrode must be correctly positioned and free of scale.

The electrode can be cleaned of encrustation's only with a non-metallic brush, and must NOT be sanded.

• The gas and water systems must be tight.

• The water pressure in the system when cold must be approx. 1.5 bar; otherwise bring it to that value.

• The circulating pump must not be blocked.

• The expansion vessel must be charged to 1.0 bar with no system pressure.

• The gas flow and Inlet working pressure must match that given in the respective tables.

• The condense pipework must be solvent weld, sealed & free of debris or blockages.

• The condense trap must be full of water.

• Check the quality of the water in the heating system via an "alkalinity test" (checking the inhibitor concentration).

• Check the condition of the insulation within the exchanger & around the burner (Replace if cracked or damaged).

• Check the flexible gas connection between the valve and Venturi.

• Replace the burner gasket if damaged or over 5 years.

• Finally, always check the combustion parameters (see "checking the combustion values").

Replacement of major components & testing

After replacing the gas valve, burner, electrode or circuit board, it is necessary to carry out the 100% calibration (see

“100% calibration” on page 23). Then follow the instructions in par. “Checking the combustion values” on page 22.

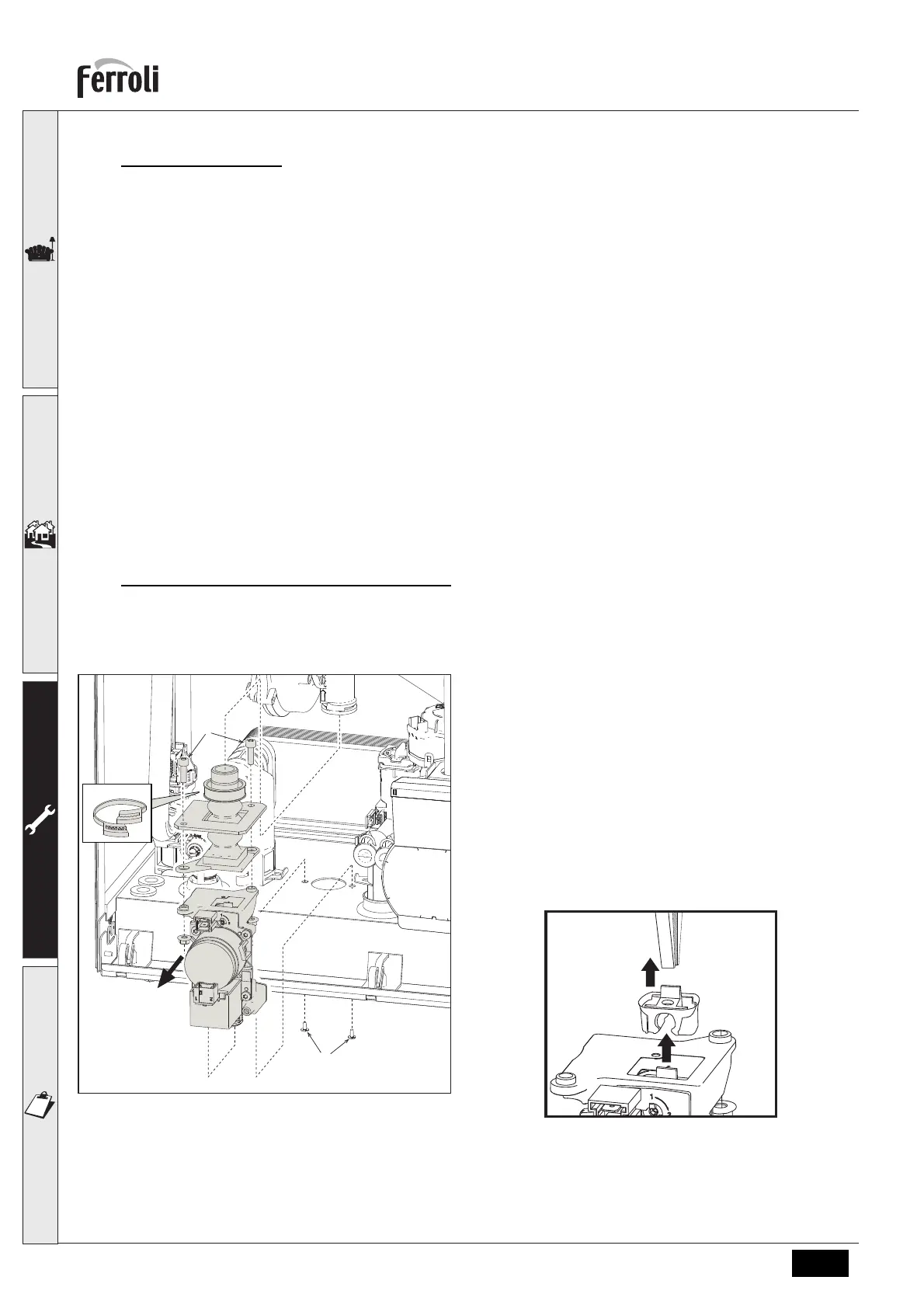

Gas valve

fig. 36- Gas valve replacement

• Disconnect the power supply and turn off the isola-

tion valve upstream of the gas valve.

• Disconnect the two electrical connectors to the gas

valve

• Disconnect the gas supply pipe to the gas valve

• Undo the screws “1”

• Remove the clamp “2”

• Remove the gas valve “3”

• Then undo the screws “4”

• Fit the new valve, carrying out the above steps in

reverse order.

Refer to the instruction sheet included in the kit

when replacing the gas Injector cartridge..

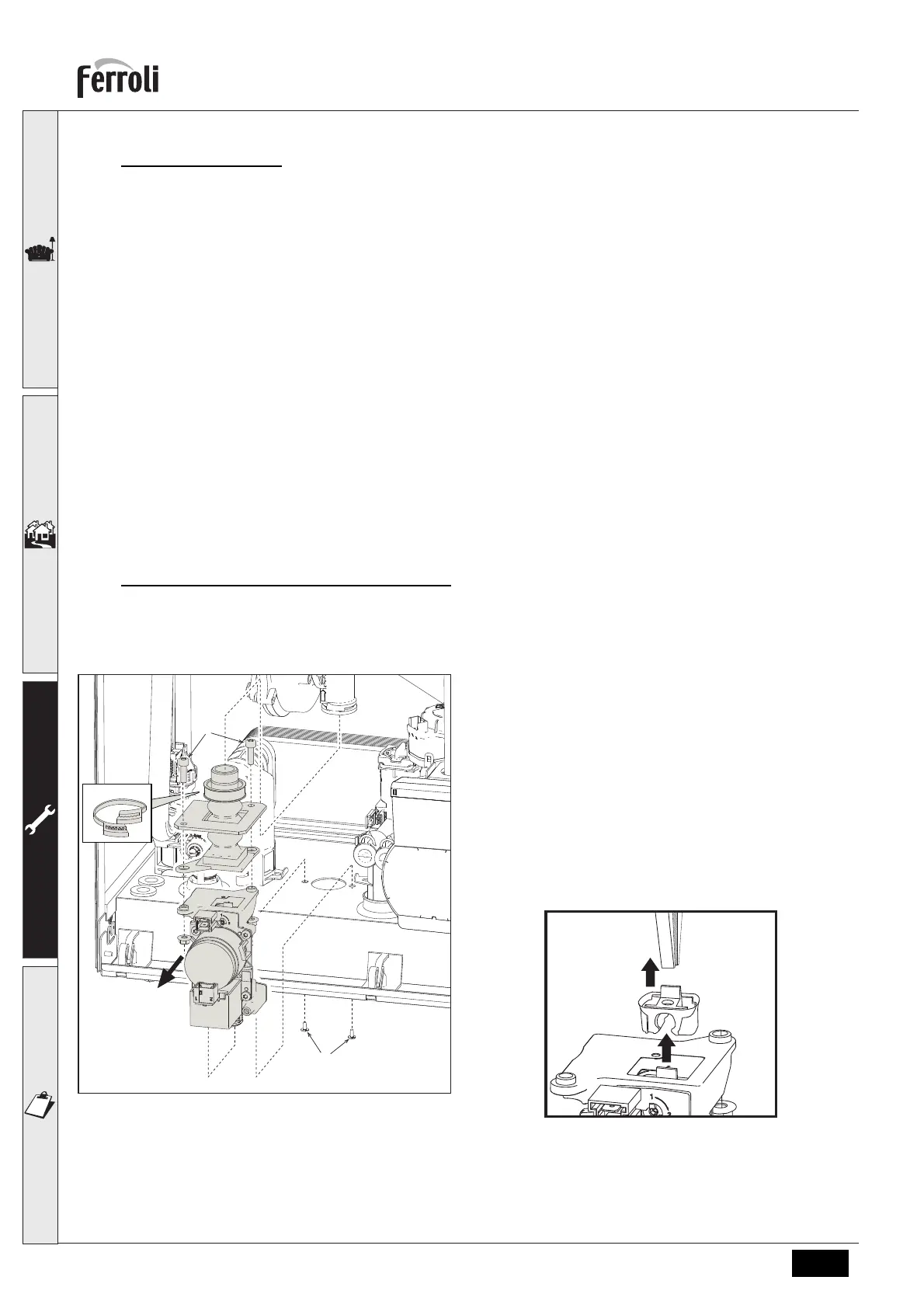

fig. 37- Gas Injector cartridge replacement

1

4

2

3

Loading...

Loading...