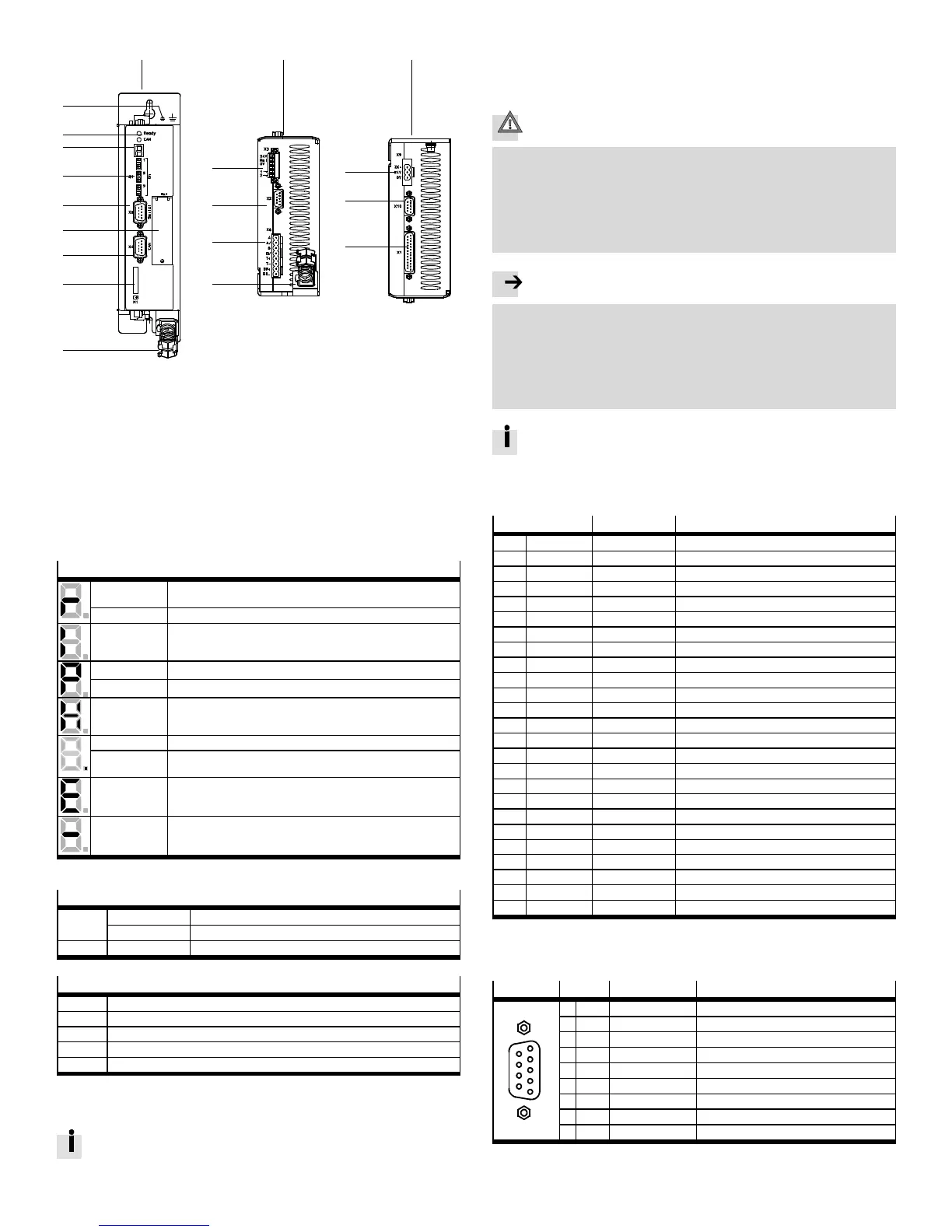

2 Product overview

2.1 Device view

123

4

5

6

7

8

9

aJ

aA

aB

aC

aD

aE

aF

aG

aH

aE

1 Front view

2 View underneath

3 View on top

4 Earthing screw (central FU

connection)

5 LED status display

6 7-segments display

7 [S1]: DIP switch

8 [X5]: RS232/RS485

9 [EXT]: Slot for CAMC-...

aJ [X4]: CAN bus

aA [ M1]: SD memory card

aB [ X3] STO interface

aC [ X2] Encoder

aD [ X6] Motor

aE Shield connection terminal

aF [X9] Power supply

aG [ X10] Master/slave

aH [ X1] I/O interface

Fig. 1 Motor controller CMMS-ST-...-G2

2.2 Display and control elements

7-segments display

1)

Rotating out-

side segments

Speed mode (speed adjustment):

Display changes corresponding to rotor position and speed.

Middle segment Controller enable active (motor is energised).

I Force mode (current control).

Pxxx Positioning mode, record number x x x

PHx Homing phase x

H Two-channel safety function requested (DIN4 [X1.21] and Rel [X3.2]).

POINT Start program (Bootloader) active.

Flashing point – Firmware file (memory card) is being read.

– Display of errors th rough the start program.

Exxy Error (E = error)

Number: Two -position main index (x x), single-position subindex (y )

Example: E 0 1 0 Section 7.

–xxy– Warning

Number: Two -position main index (x x), single-position subindex (y ).

Example:-170- Section 7.

1) Several characters are displayed one after the other.

LED display

Ready Green Operating status/controller enable

Flashing green Parameter file (memory card) is being read/written

CAN Yellow Status display: CAN bus active

DIL switch

S1.1 … 7 CAN bus address o r MAC-ID

S1.8 Automatic loading of new firmware from memory card

S1.9 … 10 Setting th e CAN-bus transmission rate

S1.11 Activatio n of the CAN-bus interface

S1.12 Terminating resistor for CAN-bus

3 Mechanical installation

3.1 Mounting

Observe the information on the installation dimension s and free spaces in

the Mounting and installation description GDCP-CMMS-ST-G2 -HW-. ..

For vertical mounting onto a control cabinet mounting plate:

• Use the motor controller exclusively in a control cabinet:

– mounting position vertical with the power supply lines [X9] on top

– attachment to the mounting holes with two M4 screws.

4 Electrical installation

Caution

Danger from unexpected movement

Faulty pre-assembled lines may destroy the electronics and trigger unexpected

movements of the motor.

• When wiring the system, use only the supplied plug connectors and preferably

the cables listed in the catalogue as accessories.

www.festo.com/catalogue

• Lay all flexible lines so that they are free of kinks and free of mechanical

stress; if necessary in an energy chain.

Note

ESD (electrostatic discharge) can cause damage to the device or other system

parts at plug connectors that are not used.

• Before installation: Earth the system parts and use appropriate ESD equip-

ment (e.g. shoes, earthing straps etc .).

• After installation: Seal unassigned D-sub plug connectors with protective caps

(available at authorized dealers).

• Observe the handling specifications for electrostatically sensitive devices.

Observe the information on safe and EMC-suitable installation and on

protective earthing in the mounting and installation description, G DCP-

CMMS-ST-G2-HW-....

4.1 I/O interface [X1]

Pin

Value Assignment in 0 mode – positioning

1 SGND 0V Screening for analogue signals

2 DIN12/AIN0 –/max. 30 V Mode bit 0/setpoint input 0

2)

3 DIN10 – Record selection bit 4 (high active)

4 +VREF +10V ±4 % Reference output for setpoint value potentiometer

5 – – –

6 GND24 – Reference po tential for digital I/O modules

7 DIN1 – Record selection bit 1 (h igh active)

8 DIN3 – Record selection bit 3 (h igh active)

9 DIN5 – Controller enable (high active)

10 DIN7 – Limit switch 1

11 DIN9 – Mode bit 1

12 DOUT1 24 V 100 mA Motion complete (h igh active)

1)

13 DOUT3 24 V 100 mA Common error (low active)

1)

14 AGND 0V Reference potential for analogue signals

15 DIN13/#AIN0 –/Ri = 20 kΩ Stop (lo w active)/reference potential AIN0

2)

16 DIN11 – Record selection bit 5 (h igh active)

2)

17 AMON0 0…10V±4% Output: analogue monitor 0

18 +24VDC 24 V 100 mA Output: 24 V DC, looped through from [X9.6]

19 DIN0 – Record selection bit 0 (h igh active)

20 DIN2 – Record selection bit 2 (h igh active)

21 DIN4 – Output stage enable (high active)

22 DIN6 – Limit switch 0

23 DIN8 – Start for the positioning procedure (high active)

24 DOUT0 24 V 100 mA Output: Controller ready for operation (high active)

25 DOUT2 24 V 100 mA Start acknowledged (low active)

1)

1) Default setting, configurable in the Festo Configuration Tool (FCT).

2) Pin allo cation with control via analogue input

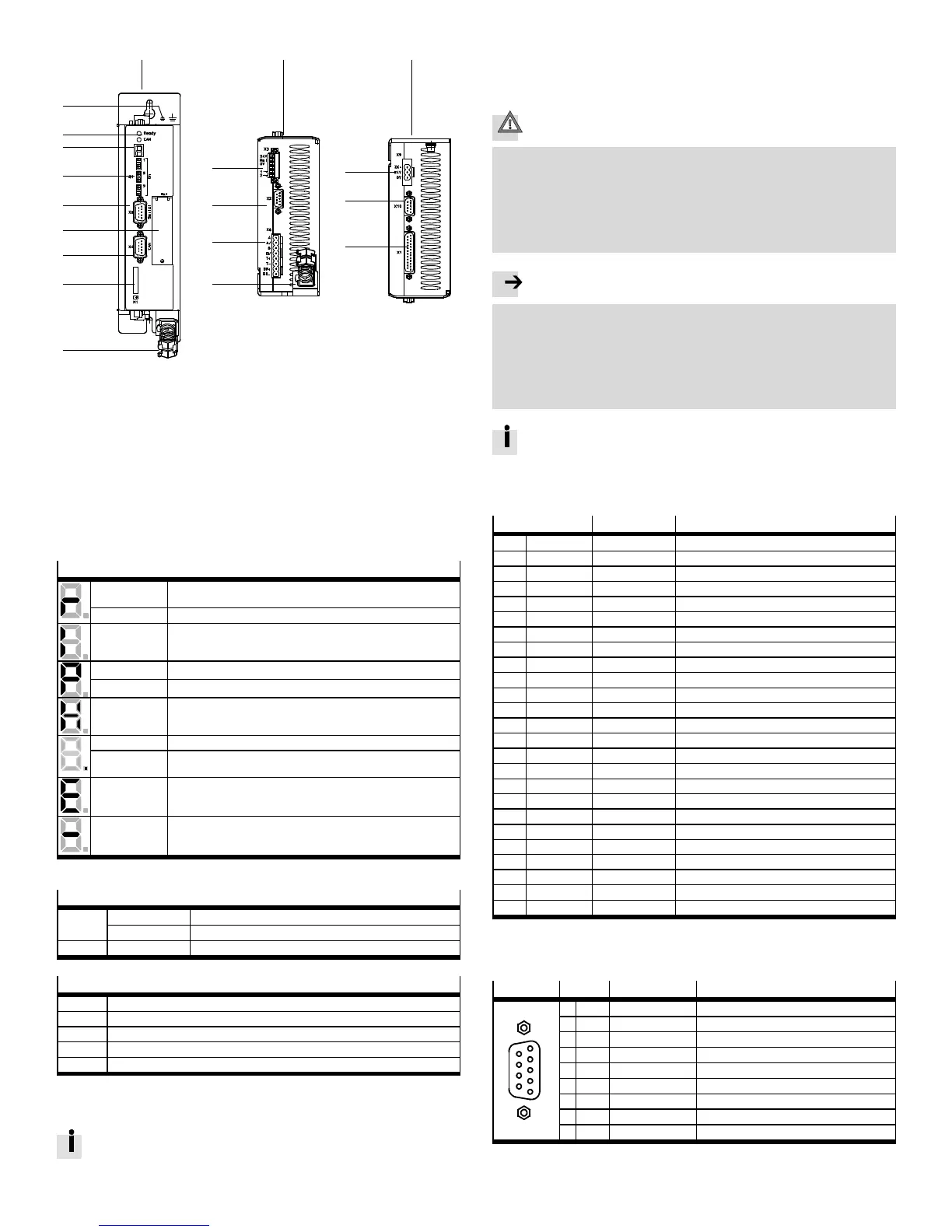

4.2 Encoder [X2]

[X2]

Pin Value

1)

Description

6

7

8

9

2

1

3

4

5

1 A+ 5 V , Ri = 120 Ohm Increment generator signal A, po sitive polarity

2 B+ 5 V , Ri = 120 Ohm Increment generator signal B, positive polarity

3 N+ 5 V , Ri = 120 Ohm Zero pulse N, positive polarity

4 GND - Reference GND for the encoder

5 VCC +5 V +-5 % 100 mA Auxiliary supply, max. 100 mA

6 A- 5 V , Ri = 120 Ohm Increment generator signal A, negative polarity

7 B- 5 V, Ri = 120 Ohm Increment generator signal B, negative polarity

8 N- 5 V, Ri = 120 Ohm Zero pulse N, negative polarity

9 GND - Internal screen for the connecting cable

1) R

i=

Internal resistance

Loading...

Loading...