8.2 Electrical Installation

WARNING!

Risk of injury due to electric shock.

• For the electric power supply, use SELV or PELV circuits that guarantee a reliable electric discon-

nection from the mains network.

• Observe IEC60204-1/EN60204-1.

1. If a screened cable is used: earth the shield at the cable end farther away from the valve.

2. Install electrical connecting cable without squeezing, kinking or stretching.

3. Tighten the electrical connecting cable onto plug M12. Tightening torque: maximum 0.3Nm

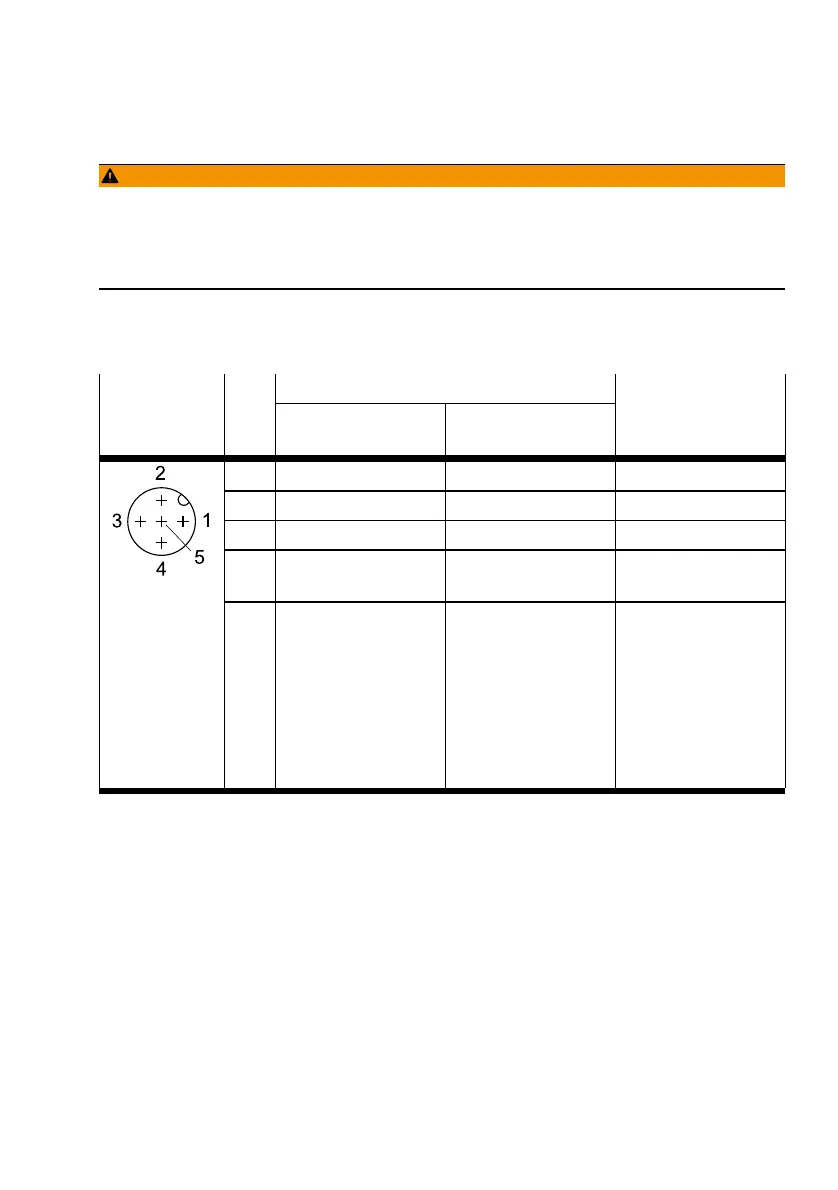

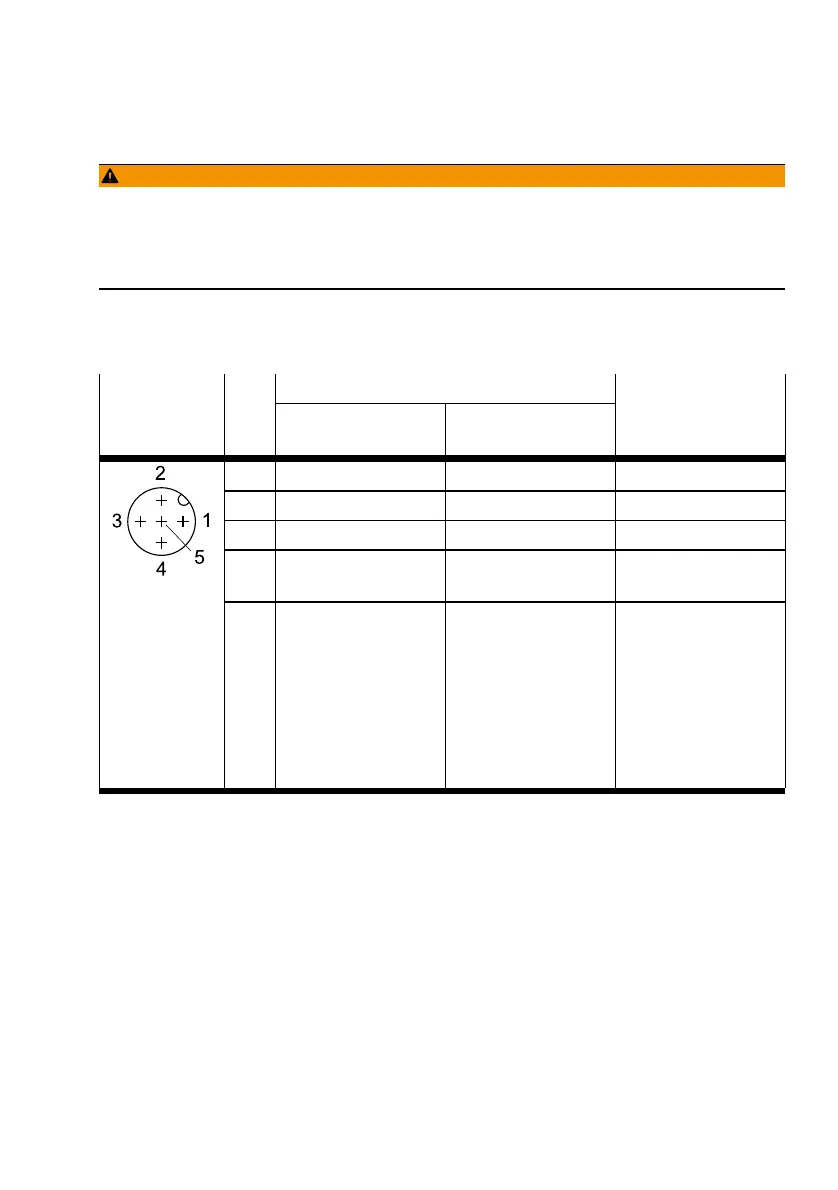

AllocationConnection Pin

Analogue Alternative (digital

input)

Wire colour

1)

(NEBU-M12...)

1 + 24 VDC + 24 VDC BN

2 Setpoint value (-) DI1 WH

3 GND GND BU

4 Setpoint value

(+)/PWM

DI0 BK

5 Actual value output

– related to pin 2

"Setpoint value (-

)" for type

VPPI -...- V1 -...

– related to pin 3

"GND" for

VPPI -...- A4 -...

DI2 GY

1) Colour code in accordance with IEC 60757:1983-01

Tab. 3 Pin Allocation for Plug M12, 5-pin

9 Commissioning

Requirements:

– The valve must be assembled.

– The pneumatic and electrical installation must be complete and checked.

1. Check operating conditions and critical limits è 14 Technical Data.

2. Switch on the power supply.

3. Switch on the compressed air supply.

4. Parameterise valve.

9.1 Parameterisation

The valve can be parameterised in the display menu using the 3 operating buttons.

Commissioning

11Festo — VPPI-...-D — 2019-12

Loading...

Loading...